A U-shaped notch processing system for impact samples

A technology for impacting specimens and processing systems, which is applied in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of low processing efficiency, high risk of injury, and low efficiency, and achieve high processing accuracy and simple operation , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

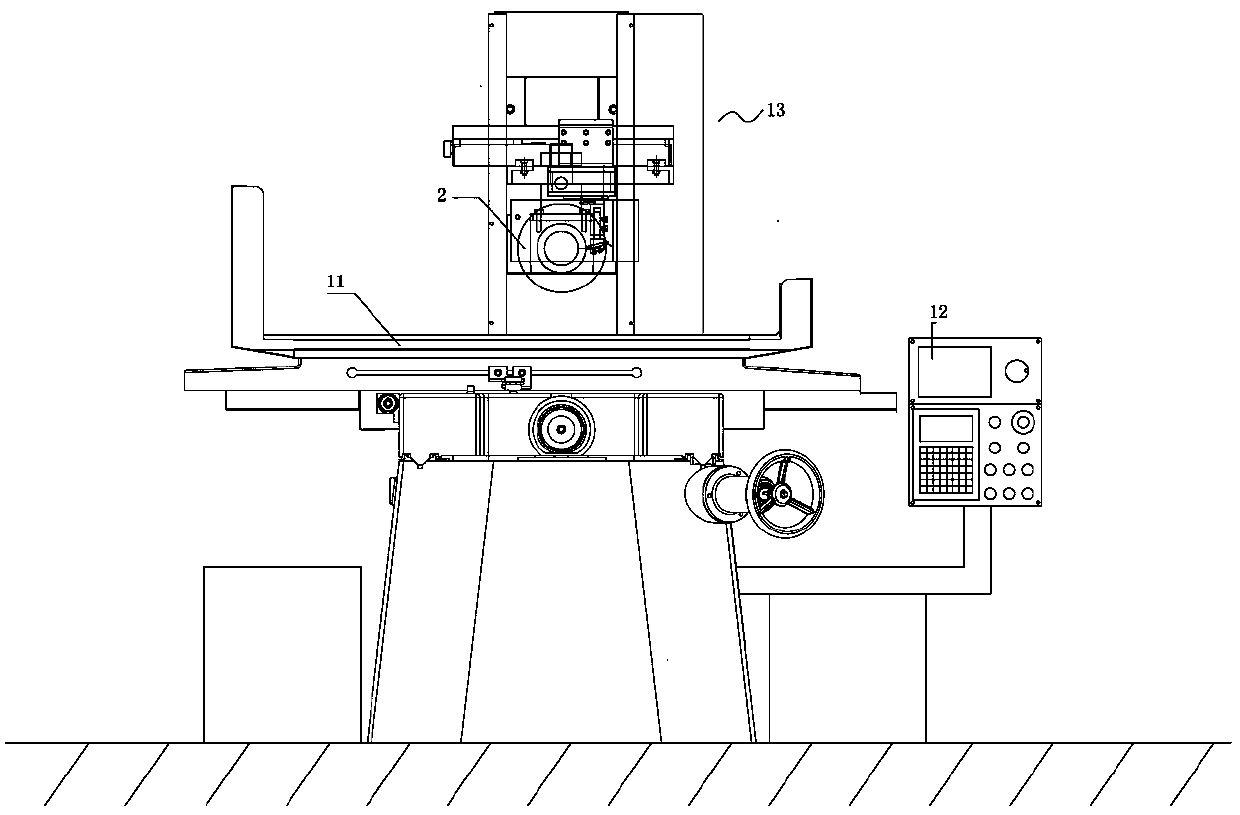

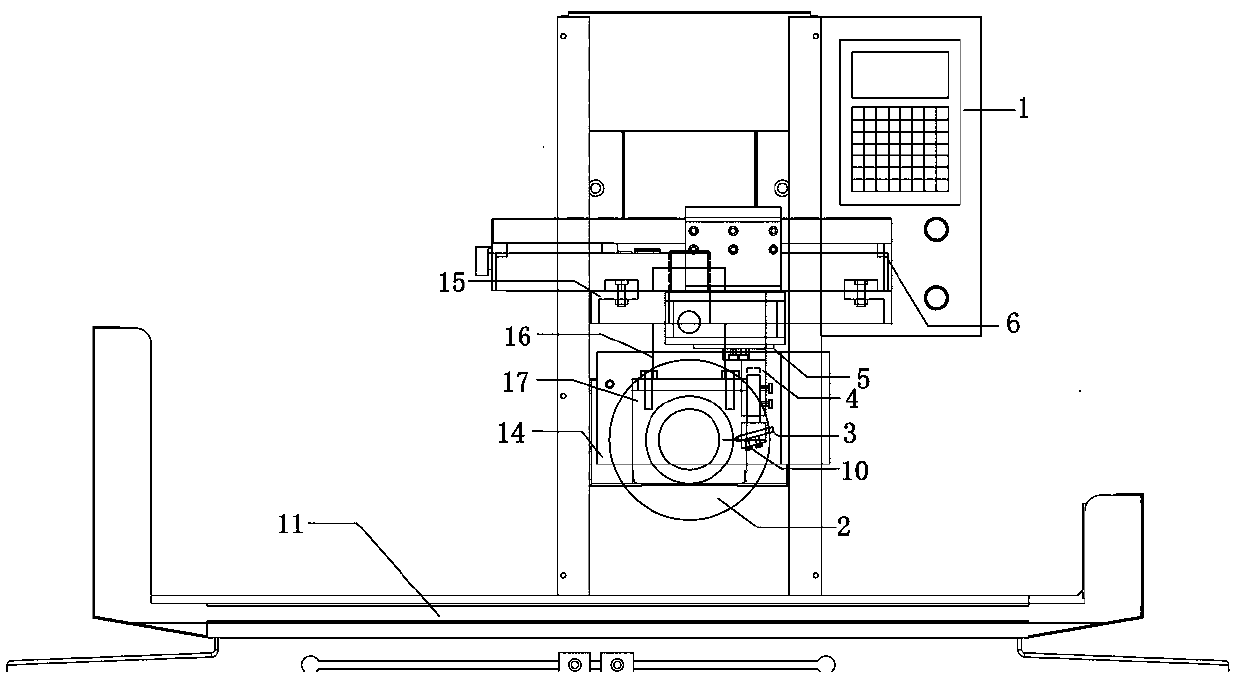

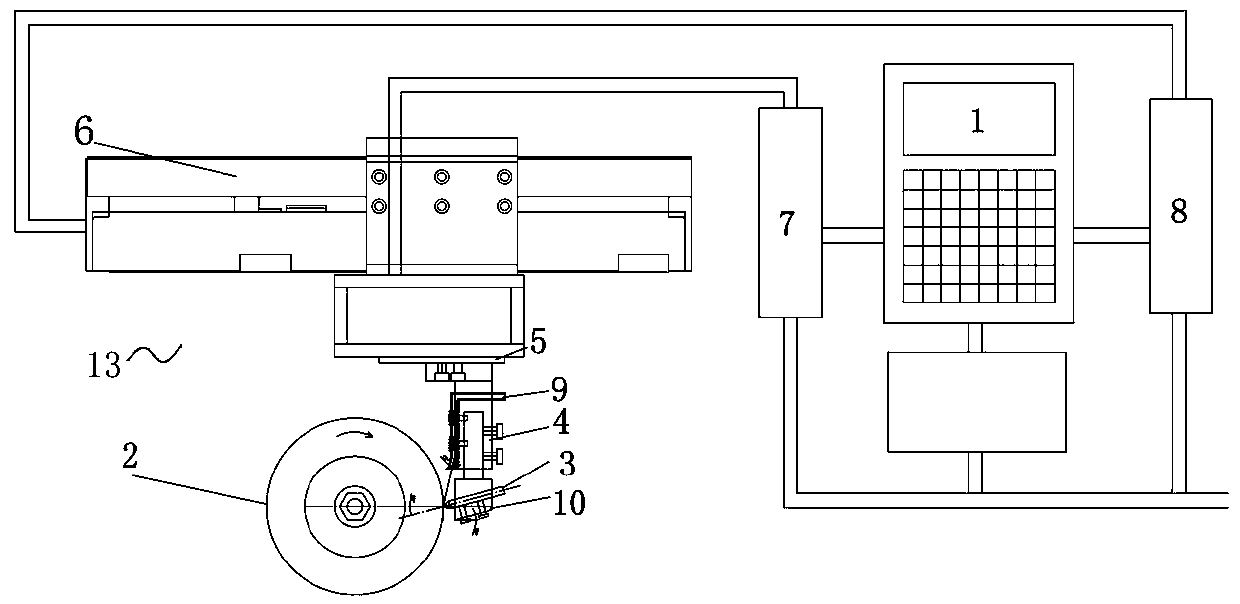

[0023] Such as Figure 1 to Figure 3 As shown, the impact sample U-shaped notch processing system includes a grinding wheel 2, a surface grinder 11, and a grinding machine control module 12 that controls the translation of the surface grinder 11. The grinding wheel 2 is located above the surface grinder 11, and also includes a grinding wheel dressing device 13. The grinding wheel dressing device 13 includes a trimming controller 1, a diamond pen 3 whose nib can be in contact with the outer edge of the grinding wheel 2, the diamond pen 3 is fixedly connected with the rotating seat 5 that can drive the diamond pen 3 to trim the outer edge of the grinding wheel 2 through the pen holder 4, and the rotating platform is located at the outer edge of the grinding wheel 2. On the mobile platform 6 that drives the rotating platform to translate relative to the outer edge of the grinding wheel 2;

[0024] The grinding wheel dressing device 13 is fixed above the grinder 11 through a brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com