Method for eliminating flat coil defect of 590Mpa dual-phase steel hot coil

A dual-phase steel, grade technology, applied in the field of steel rolling, can solve problems such as flat coil defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

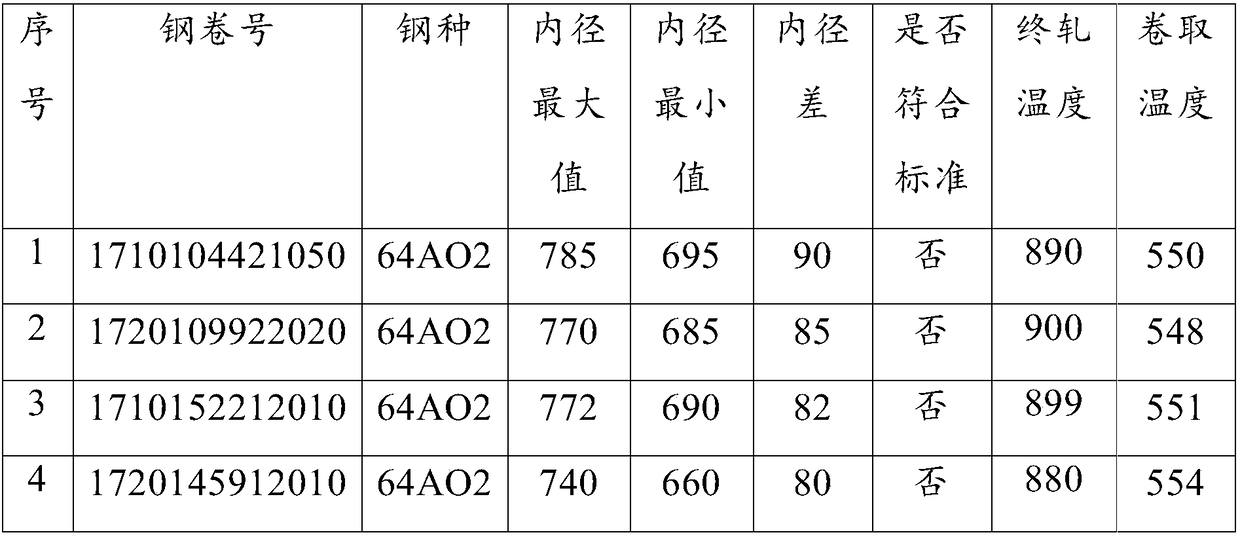

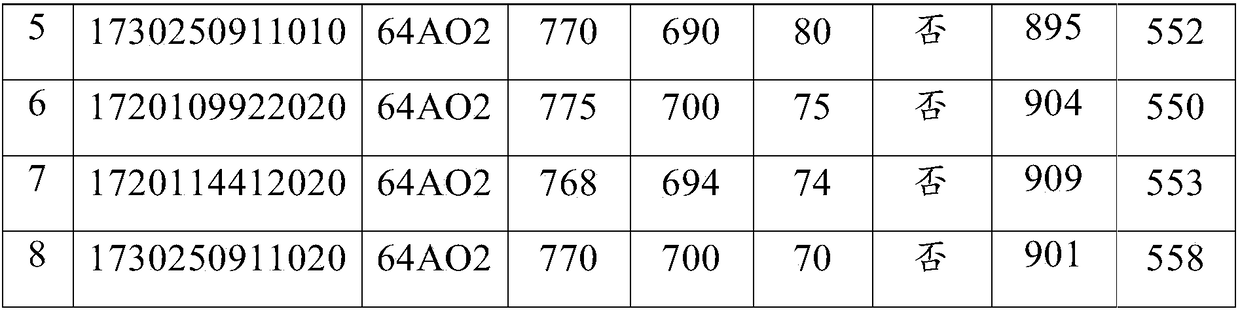

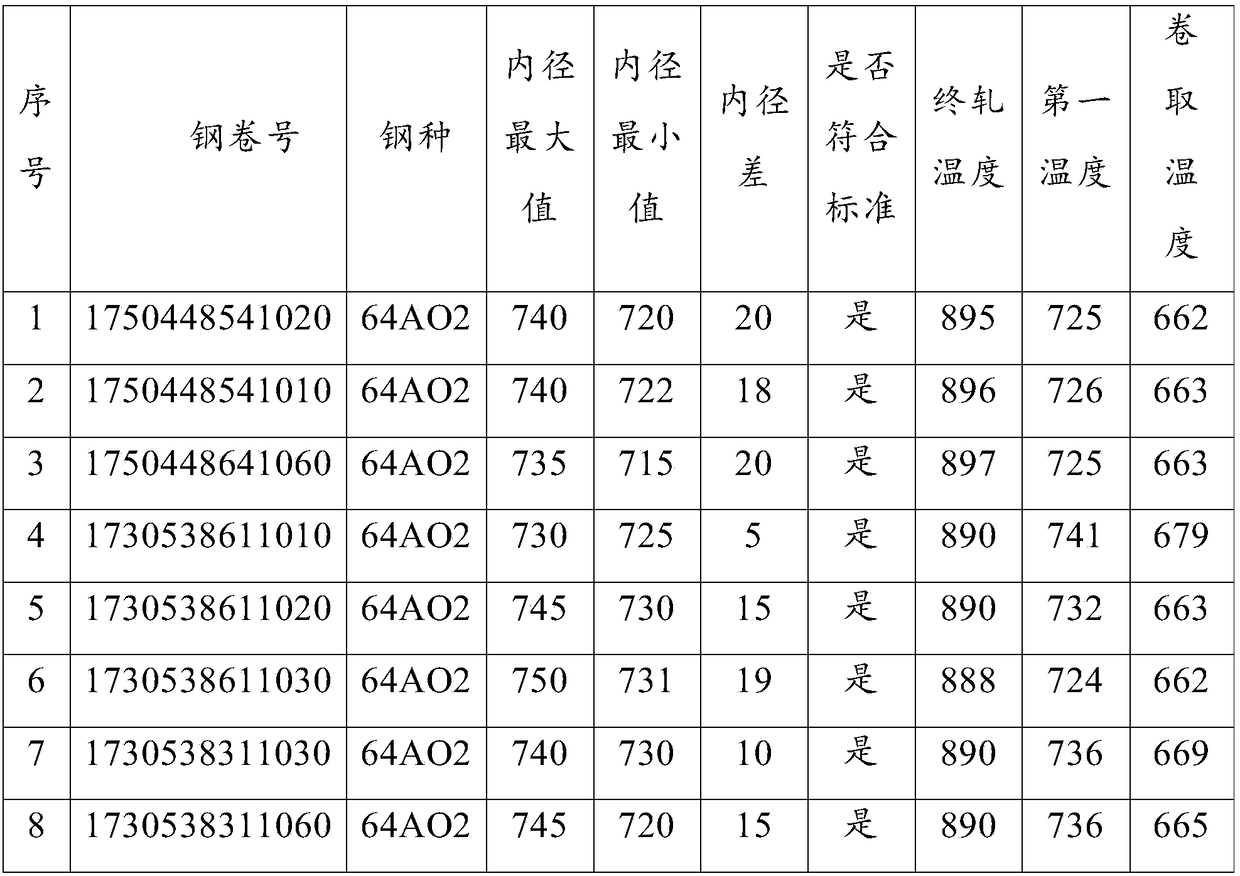

Examples

Embodiment Construction

[0022] The embodiments of the present application provide a method for eliminating defects in 590Mpa-level dual-phase steel hot coils, and solve the technical problem that 590Mpa-level dual-phase steel hot coils are prone to slab defects in the prior art.

[0023] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiments of the present application is as follows:

[0024] With the rolling process of hot-rolled strip steel, the temperature of the strip gradually decreases, and the austenite gradually transforms into other structures with lower transformation temperatures. Some of the structures have very low transformation temperatures, which will lead to A certain degree of phase change process is still maintained after coiling, resulting in a local uneven temperature field, resulting in uneven thermal expansion of the hot rolled coil due to uneven heating. The volume expansion of the outer ring of the hot coil is greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com