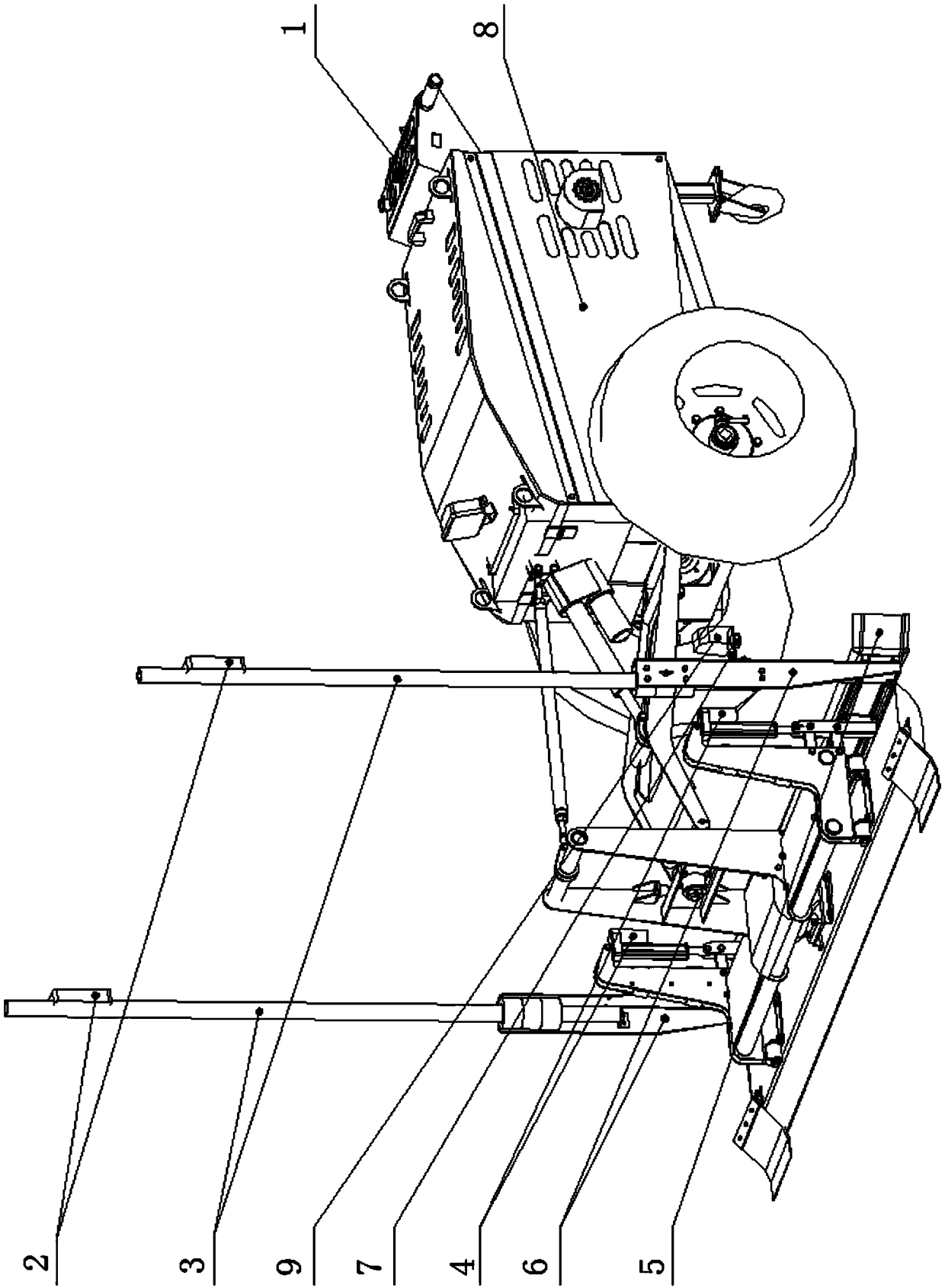

Laser paver and elevation setting method thereof

A technology of paver and laser marking instrument, which is applied to roads, road repairs, roads, etc., to achieve an intuitive effect of the elevation operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

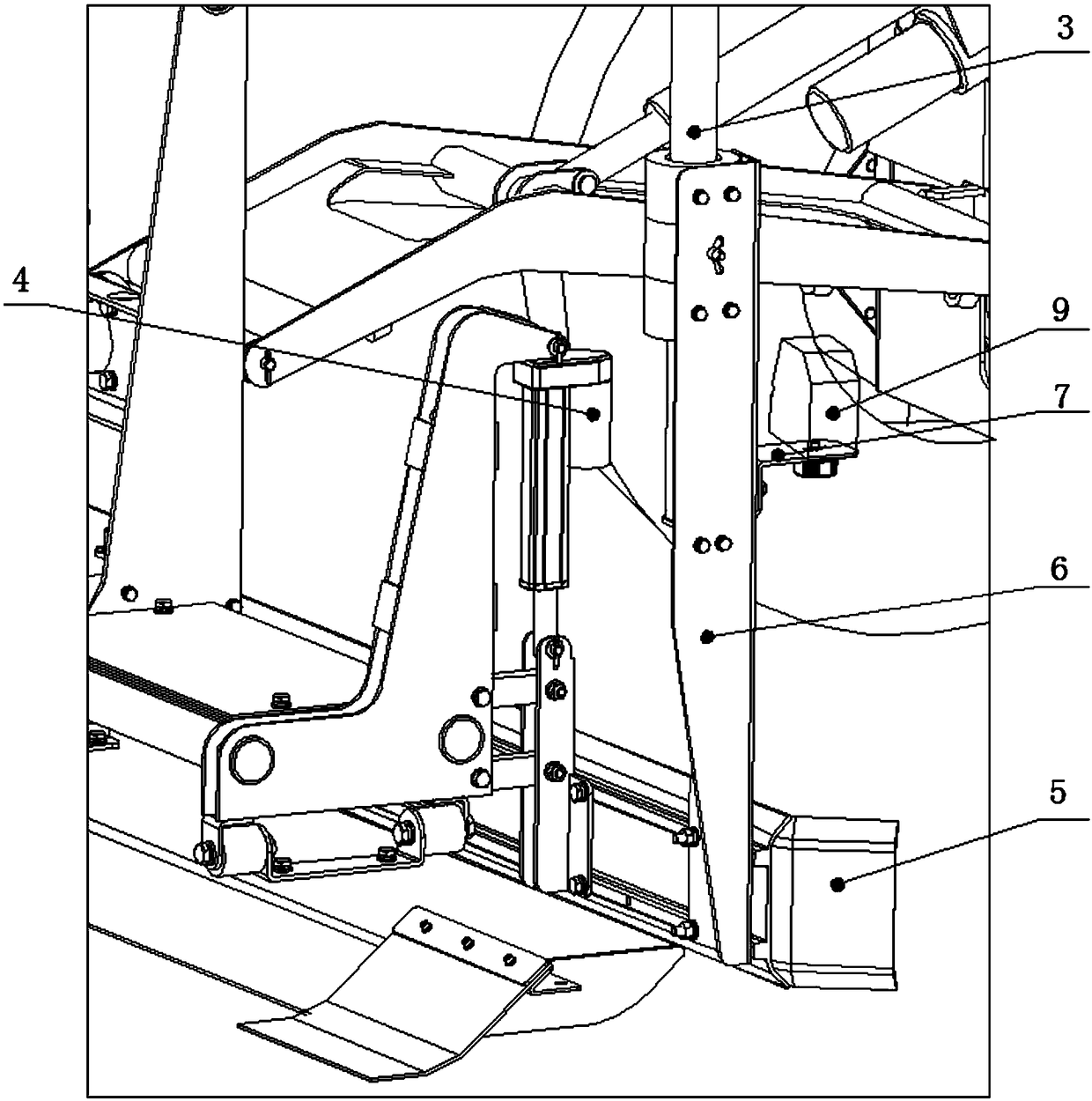

Examples

Embodiment 2

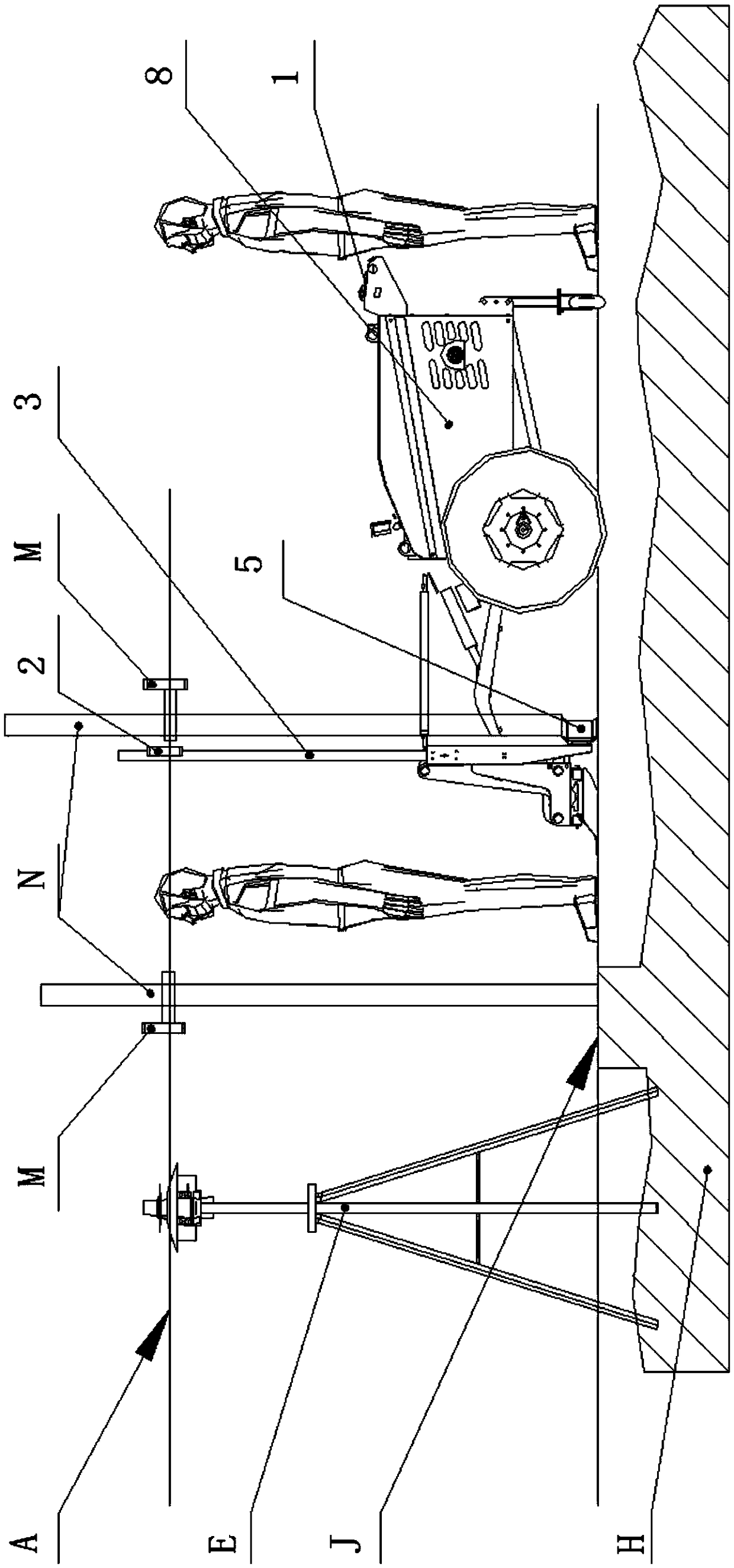

[0045] like Figure 4 , the elevation setting method of the laser paver described in the above-mentioned embodiment 1, comprising the following steps:

[0046] Step 1. Place the laser paver near the 50 line D. The 50 line D refers to the 50 line of the building. It is determined as ±0.000 on the floor surface of each floor, and ±0.000 is a reference plane of the main project. 0.000 is the benchmark and the line that is 50 cm upwards with the ink fountain on the wall W is the 50 line D. The starting surface used for the 50 line D is the reference level when paving the pavement materials. If there is no 50 line D on the construction site , can manually draw 50 lines D on any immovable object based on ±0.000; the 50 lines D can also be 60 lines, 80 lines, or 1 meter lines, because 50 lines are usually reserved on the wall W of the engineering site line, so this embodiment is preferably 50 lines; open the laser marking instrument 9 on the paver, and the laser surface B emitted by...

Embodiment 3

[0052] A working method of a laser paver, comprising the method for setting the elevation of the laser paver described in the above embodiment 2, further comprising the following steps:

[0053] During the laying process of the laser paver, when the body of the laser paver is disturbed and a receiver 2 is not at the height of the laser plane emitted by the laser sweeper E, the receiver transmits a signal to the laser paver The automatic controller of the machine, the automatic controller automatically controls the laser paver to adjust the scraper, so that the receiver returns to the height of the laser plane, and the bottom surface of the scraper returns to the reference plane.

[0054] The automatic controller adopts a single-chip microcomputer or PLC, etc.; the laser paver action drive mechanism is a drive mechanism for controlling the action of each part of the laser paver in the prior art, and it can be realized by a hydraulic system or a motor drive system.

[0055] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com