Bulkhead gate device

A slab gate and beam slab technology, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve the problems of limited weight of counterweight, difficulty in closing gates, small space for slab gates, etc., and achieves low cost, simple structure, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

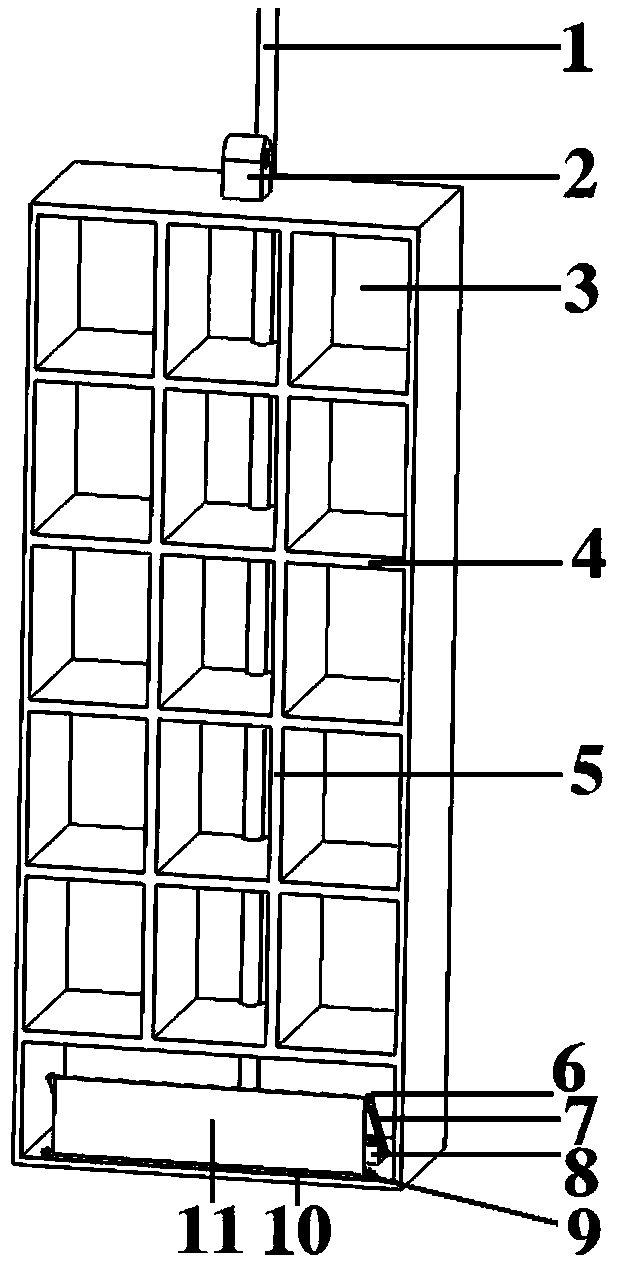

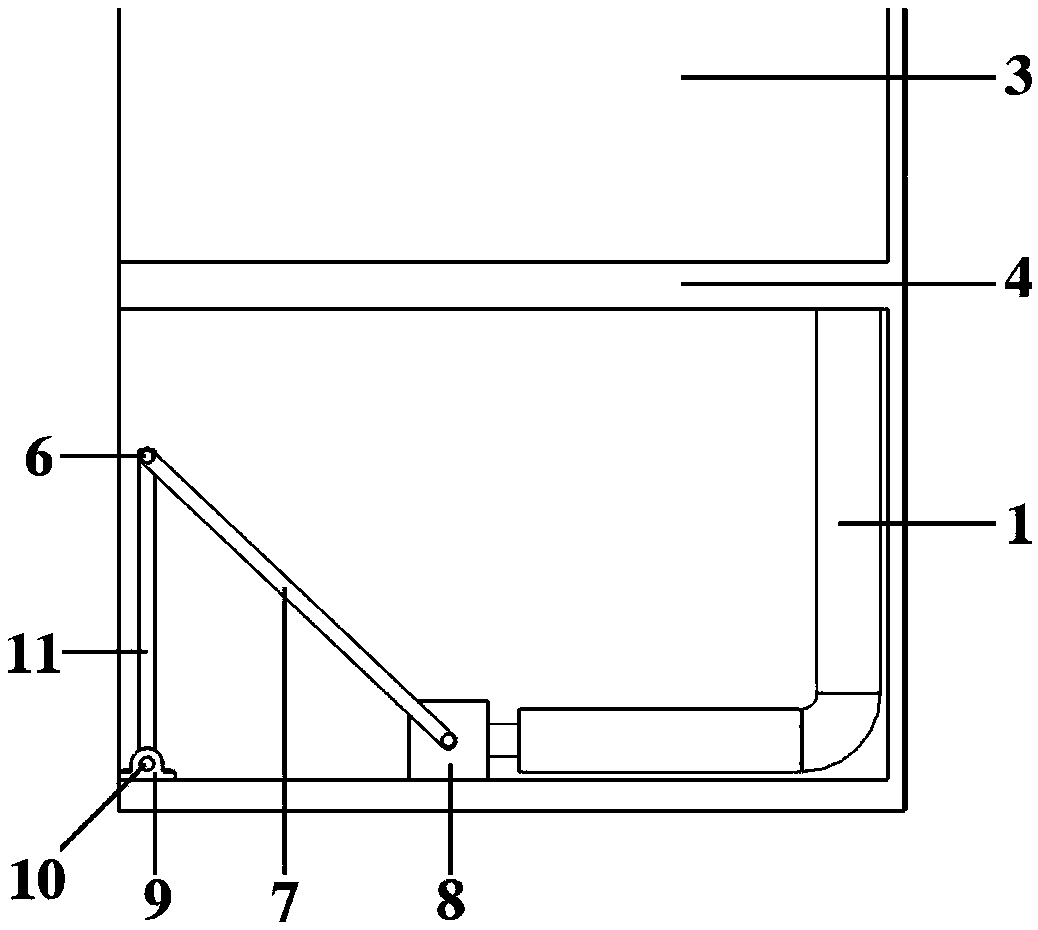

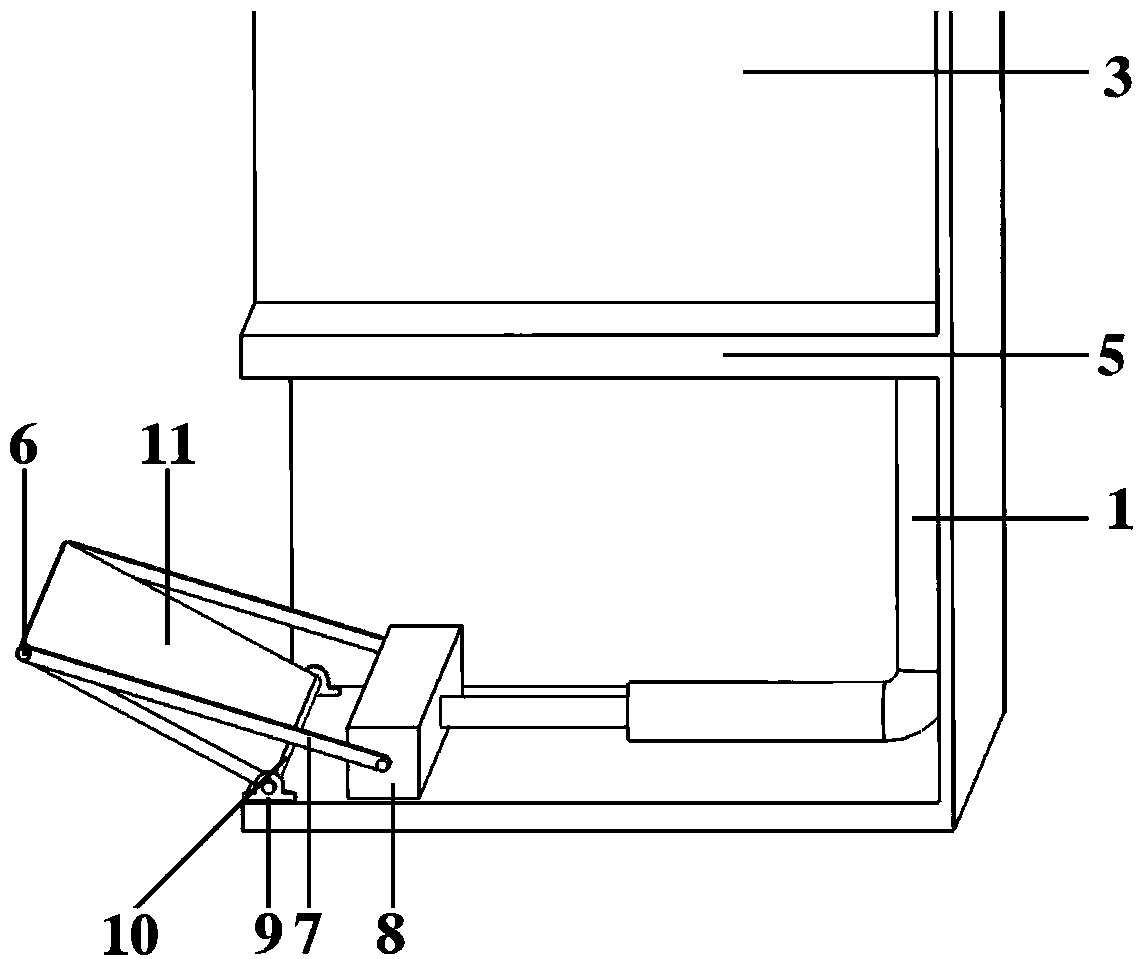

[0018] like Figure 1 to Figure 3 The flat gate device shown includes a flat gate, a hydraulic arm 1, a lifting lug 2, a warehouse 3, a beam 4, a longitudinal beam 5, a hinge point 6, a crank 7, a slider 8, a bearing seat 9, a rotating shaft 10 and a bottom edge 11 .

[0019] During the opening and closing process of the flat gate, the hoist pulls the lifting lug 2 through the pull rod to realize the lifting of the gate. The gate is made up of a series of beams 4, longitudinal beams 5, warehouses 3 between the beams and slabs. When the flat gate is closed, as the opening decreases, the water gravity and horizontal force on the gate increase simultaneously. When the gate is soaked in water for a long time, the friction coefficient will increase. When the friction coefficient is too large, the vertical force of the gate will increase. The axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com