Split floating-type large-flow overflow-preventing and blockage-eliminating floor drain

A floating, high-flow technology, applied in drainage structures, grease/oily substance/floating matter removal devices, water/sludge/sewage treatment, etc., can solve problems such as difficult maintenance and cleaning, easy blockage, and small drainage. Achieve the effect of reducing maintenance time, not easy to block, and low drainage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

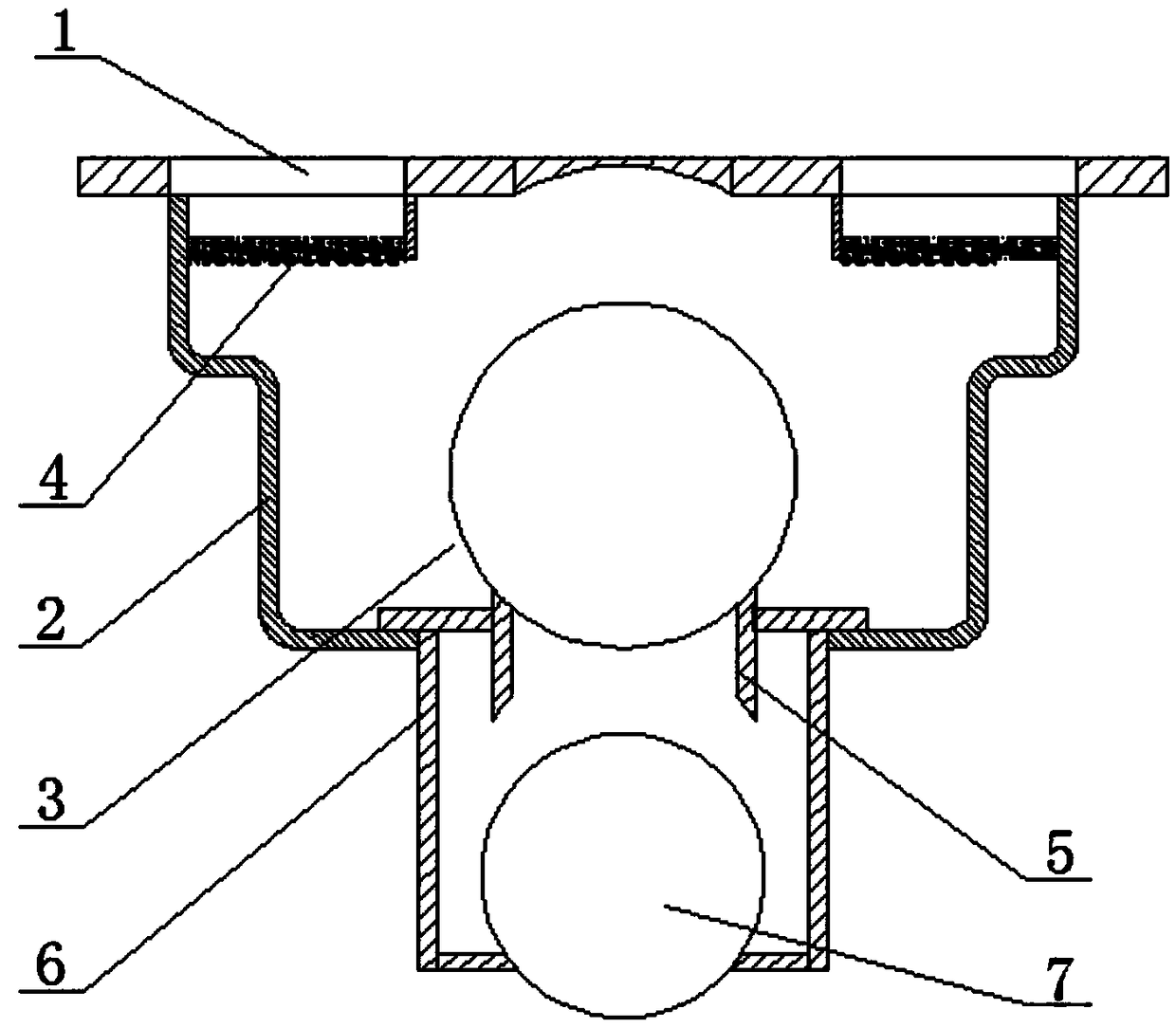

[0013] Such as figure 1 As shown, the split floating large-flow anti-overflow and blockage floor drain in this embodiment includes: a decorative panel 1, a floor drain cavity 2, a floating and deodorant sealing ball 3, an annular filter screen 4 and a dirt-separating sealing sleeve 5;

[0014] The decorative panel 1 is arranged on the top surface of the floor drain cavity 2, and the annular filter screen 4 is arranged on the upper part of the inner cavity of the floor drain cavity 2; The top of the dirt sealing sleeve 5 extends upwards to the inside of the floor drain cavity 2; the floating deodorant sealing ball 3 is arranged in the floor drain cavity 2 and is positioned above the dirt-separating sealing sleeve 5, and the floating deodorizing sealing ball 3 can be separated from the sealing sleeve 5 The top end face of the pollution sealing sleeve 5 is sealed and fitted, and the diameter of the floating and deodorant sealing ball 3 is larger than the pipe diameter of the poll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com