Glue scraping tool for prefabricated building construction

A kind of building construction and assembly technology, which is applied in the direction of architecture and building structure, and can solve the problems of tool differences, construction effects vary from person to person, and equipment is not professional enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

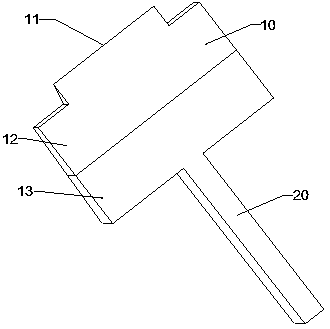

[0022] Such as figure 1 As shown, this embodiment provides a squeegee tool for prefabricated building construction. The squeegee tool is used to process the sealant of the lap joint between the wallboard and the wallboard member, including a squeegee for squeezing the glue. A rubber plate 10 and a handle 20. The rubber squeegee 10 is in the shape of a flat plate. One side of the rubber squeegee 10 is connected with a handle 20, and the other side is a rubber squeegee 11, which has a convex structure.

[0023] Further, the front and back surfaces of the squeegee plate 10 are not parallel, and the intersection line is the squeegee edge 11.

[0024] Further, the rubber squeegee 10 is quadrilateral, and the handle 20 is arranged on the side opposite to the rubber squeegee 11. The squeegee board 10 is a flat plate with a certain thickness. Specifically, the squeegee edge 11 having a convex structure is one of the sides of a quadrilateral. The squeegee board 10 is rectangular, and the sq...

Embodiment 2

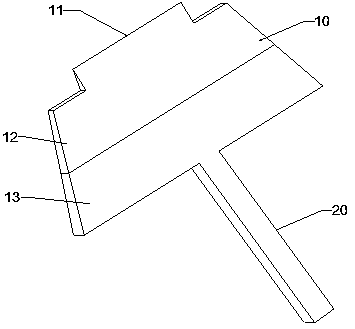

[0034] Such as figure 2 As shown, this embodiment provides a squeegee tool for prefabricated building construction. The squeegee tool is used to process the sealant of the lap joint between the wallboard and the wallboard member, including a squeegee for squeezing the glue. A rubber plate 10 and a handle 20. The rubber squeegee 10 is in the shape of a flat plate. One side of the rubber squeegee 10 is connected with a handle 20, and the other side is a rubber squeegee 11, which has a convex structure.

[0035] Further, the front and back surfaces of the squeegee plate 10 are not parallel, and the intersection line is the squeegee edge 11.

[0036] Further, the rubber squeegee 10 is quadrilateral, and the handle 20 is arranged on the side opposite to the rubber squeegee 11. The squeegee board 10 is a flat plate with a certain thickness. Specifically, the squeegee edge 11 having a convex structure is one of the sides of a quadrilateral. The squeegee board 10 is trapezoidal, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Protrusion height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com