Full-automatic lock

A fully automatic, lock-body technology, applied in non-mechanical transmission-operated locks, building locks, buildings, etc., can solve the problems of fragile internal structure, uneven speed, low stability, etc. Powerful, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

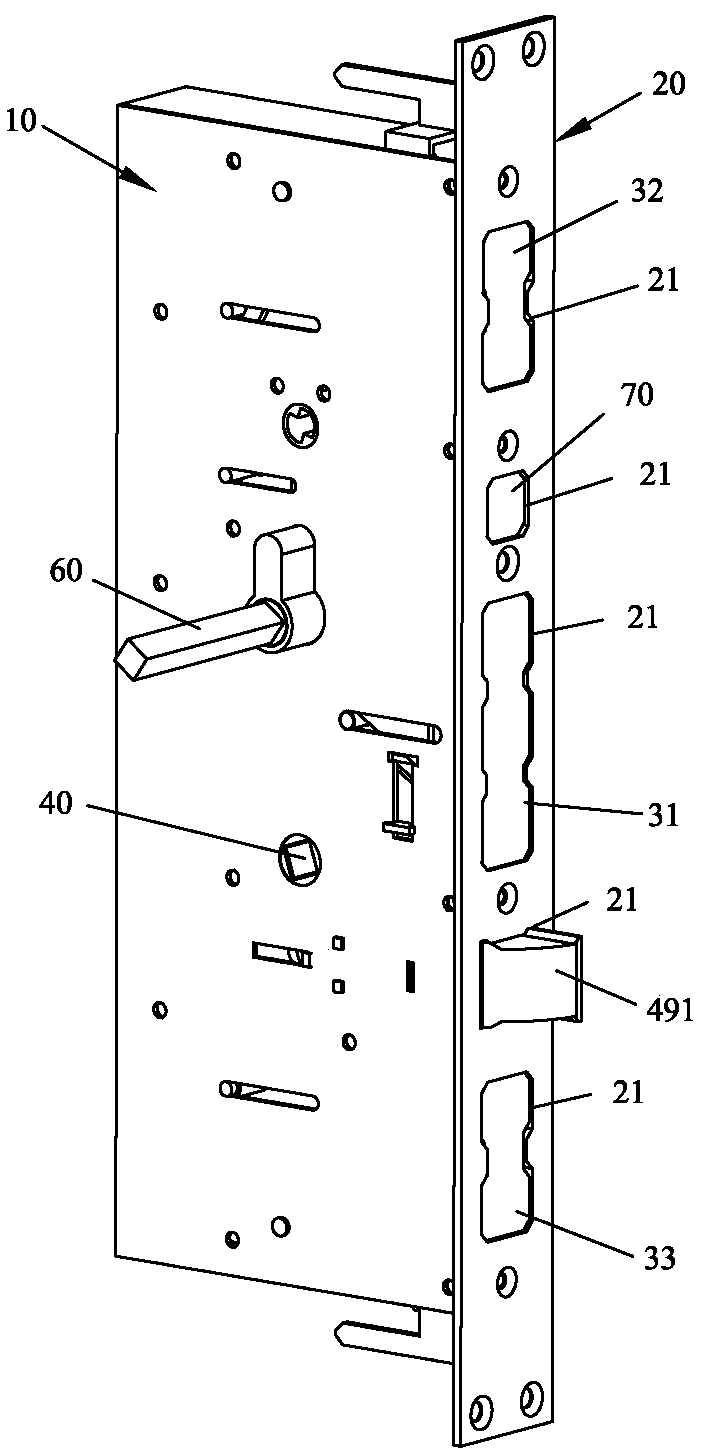

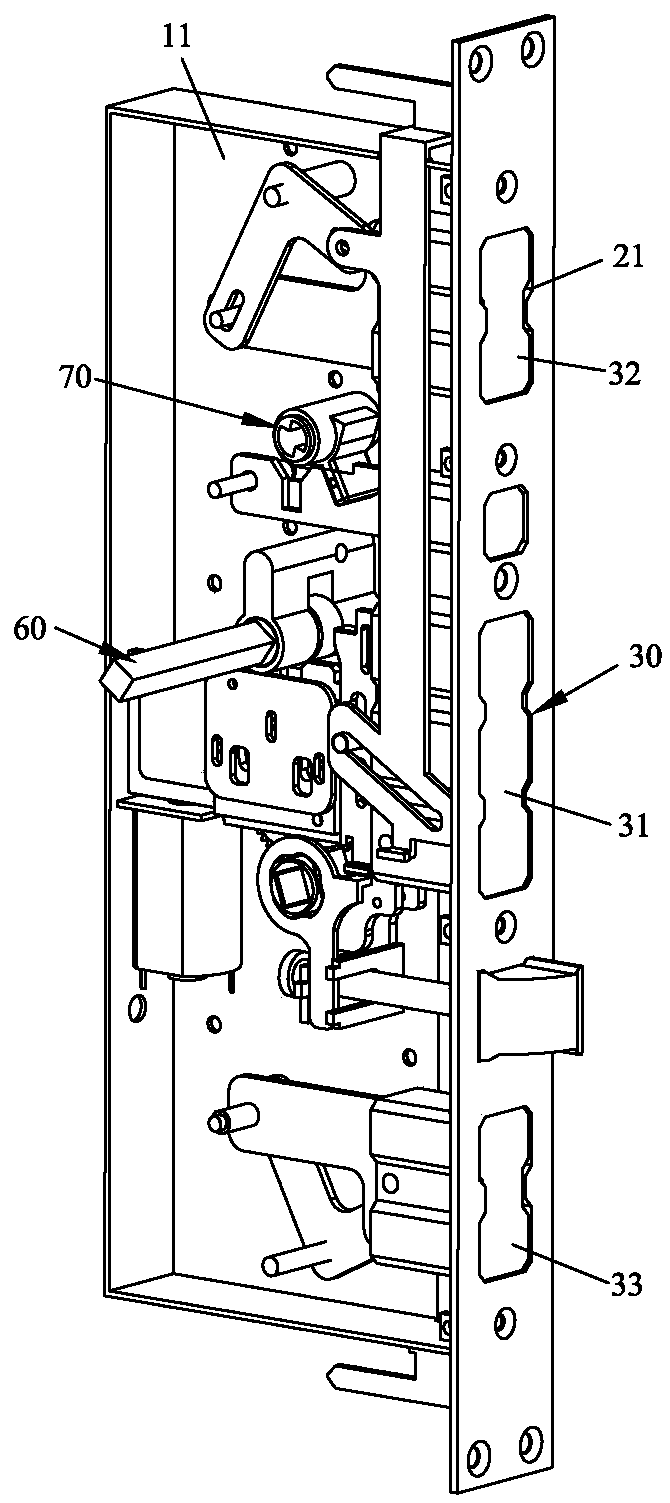

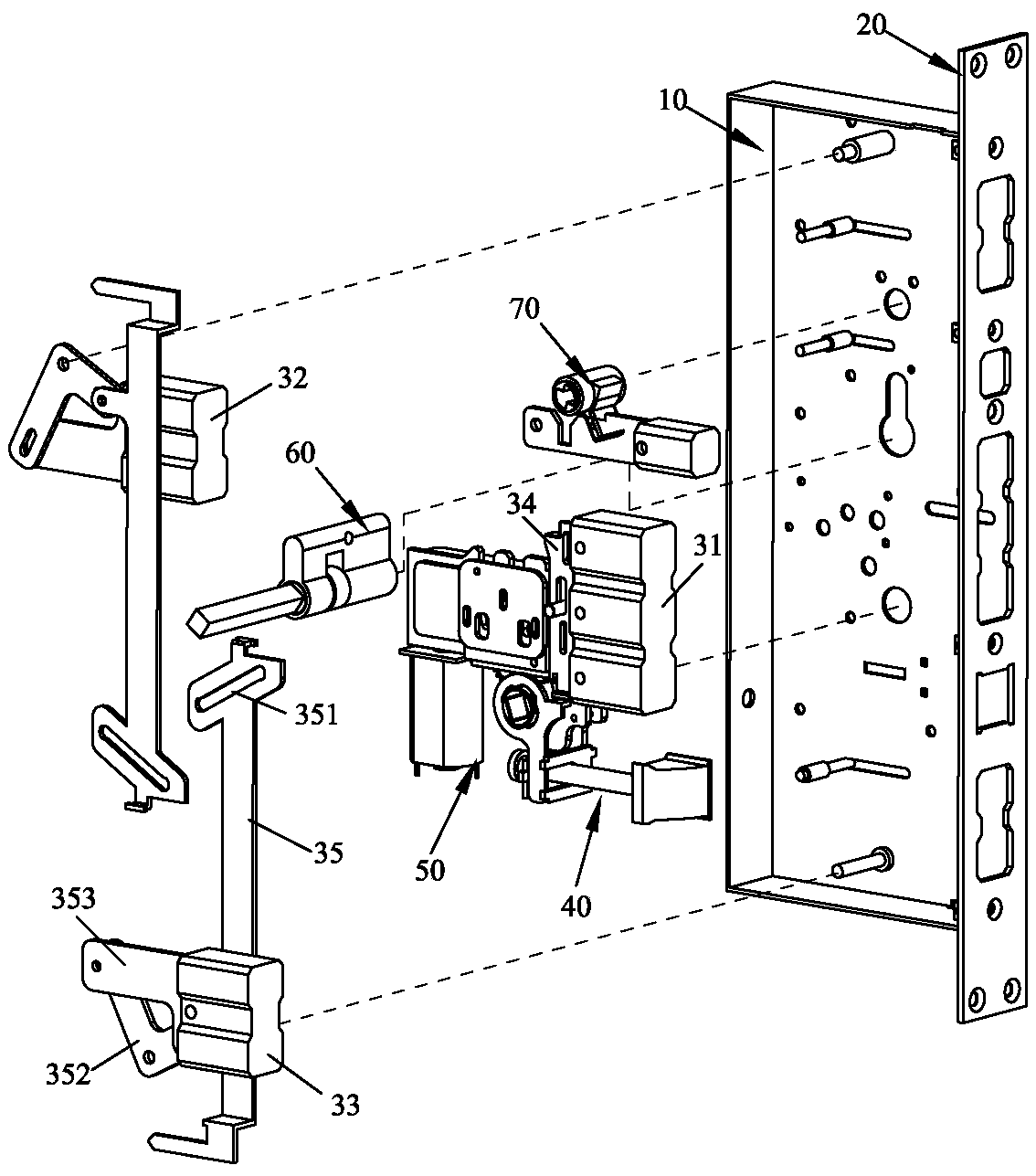

[0045] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the preferred embodiment of the present invention, which is a fully automatic lock body, including lock box 10, side panel 20, main bolt assembly 30, oblique bolt assembly 40, gear box 50, also includes lock cylinder assembly 60, anti-lock assembly 70.

[0046] Wherein, an accommodating space 11 is formed between the lock box 10 and the side panel 20, and the main bolt assembly 30, the oblique bolt assembly 40, and the gear case 50 are all installed in the accommodating space 11. The panel 20 is provided with a through hole 21 for the main bolt and the oblique bolt to protrude. When each dead bolt stretches out of the through hole 21, it means that it is locked. When each dead bolt retracts into the through hole 21, the surface is unlocked and the door can be opened.

[0047] The gear box 50 includes a motor 51, a box body 52, a transmission gear set 53, and a rack plate 54. The transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com