A Calculation Method for Gravel Packing in Horizontal Wells

A gravel filling and simulation computing technology, applied in the fields of sand control of oil wells, oil and natural gas engineering, can solve problems such as difficult to simulate flow laws, and achieve the effect of meeting the requirements of on-site safe operation and high-quality operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

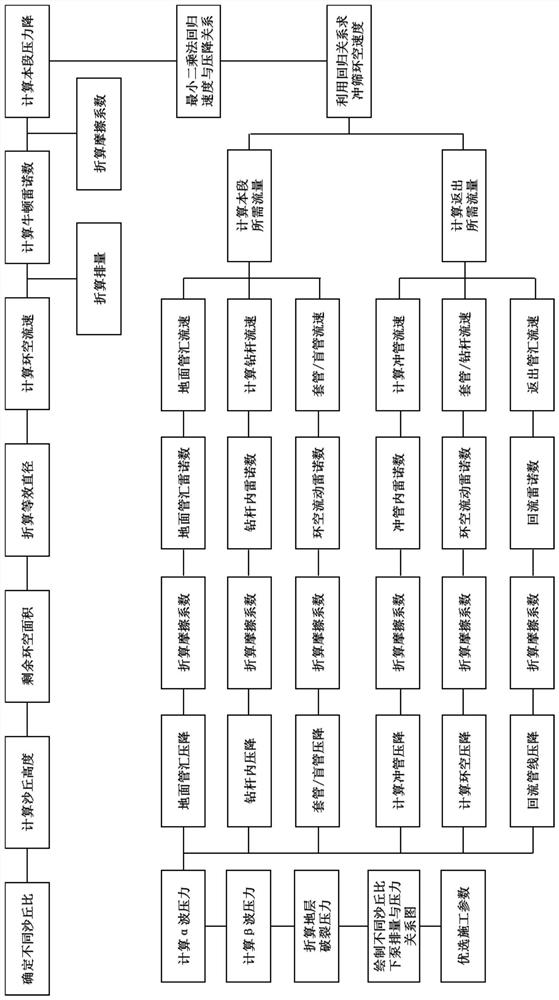

[0042] The embodiment of the present invention provides a horizontal well gravel packing simulation calculation method, see figure 1 , the method includes the following steps:

[0043] 101: According to the size parameters of the filling tool and the formation parameters, calculate and maintain the annular velocity and displacement of the balanced embankment under different dune ratios;

[0044] 102: Determine the friction and pressure drop of the annulus section of the filling operation according to the annulus flow velocity and displacement, and use the least square method to return the annulus flow velocity and displacement of the flushing pipe and screen pipe;

[0045] 103: Calculate the pressure drop of each manifold node in the inflow section and each annulus node in the filling return section in the gravel packing operation;

[0046] 104: Calculate the pressure generated by the α wave at the bottom of the screen during the filling operation, the pressure generated by t...

Embodiment 2

[0050] The scheme in embodiment 1 is further introduced below in conjunction with specific calculation formulas and examples, see the following description for details:

[0051] Step 1: Collect the basic parameters of the gravel packing operation;

[0052] Among them, this step includes: formation parameters (formation pore pressure gradient, formation fracture pressure gradient, open hole leakage rate); wellbore parameters (length of filled open hole section, maximum inclination angle, wellbore size); filling tool parameters (ground The inner and outer diameter and length of the manifold, the inner and outer diameter and length of the drill pipe, the inner and outer diameter and length of the filling tool assembly, the inner and outer diameter and length of the screen pipe, the inner and outer diameter and length of the flushing pipe, and the roughness of the pipe string); filling Medium parameters (sand-carrying liquid viscosity, sand-carrying liquid density, gravel density,...

Embodiment 3

[0115] The scheme in embodiment 1 and 2 is carried out feasibility verification below in conjunction with specific example, see the following description for details:

[0116] 1. Basic data collation

[0117] (1) Drilling tool parameters

[0118] tool depth Length / ft Outer diameter / in Inner diameter in Surface Pump Into Manifold 200 3 2 Drill pipe 1 3900 3900 5.5 4.788 Drill pipe 2 6800 3000 5.5 4.788 blind leg 7000 200 5.5 4.892 screen tube 8400 1400 6.4 4.892 Flushing pipe 1550 4 3.34

[0119] (2) Formation and borehole data

[0120]

[0121] 2. According to the relevant method in step 2, calculate the pump displacement under different sand dune ratio conditions

[0122] sand dune 0.5 0.6 0.7 0.75 0.785 0.83 0.86 0.88 sand height / in 4.59 5.51 6.43 6.89 7.21 7.62 7.89 8.08 Balance dike area / in 2

8.408 12.025 17.338 21.098 23.589 26.577 28.405 29.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com