Construction method for shield machine passing through air shaft

A construction method and technology of shield machine, which can be used in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of high safety, complicated construction steps, inability to have both fast and convenient installation, etc., and achieve high stability and easy installation. and later dismantling, facilitating the effect of subsequent dismantling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

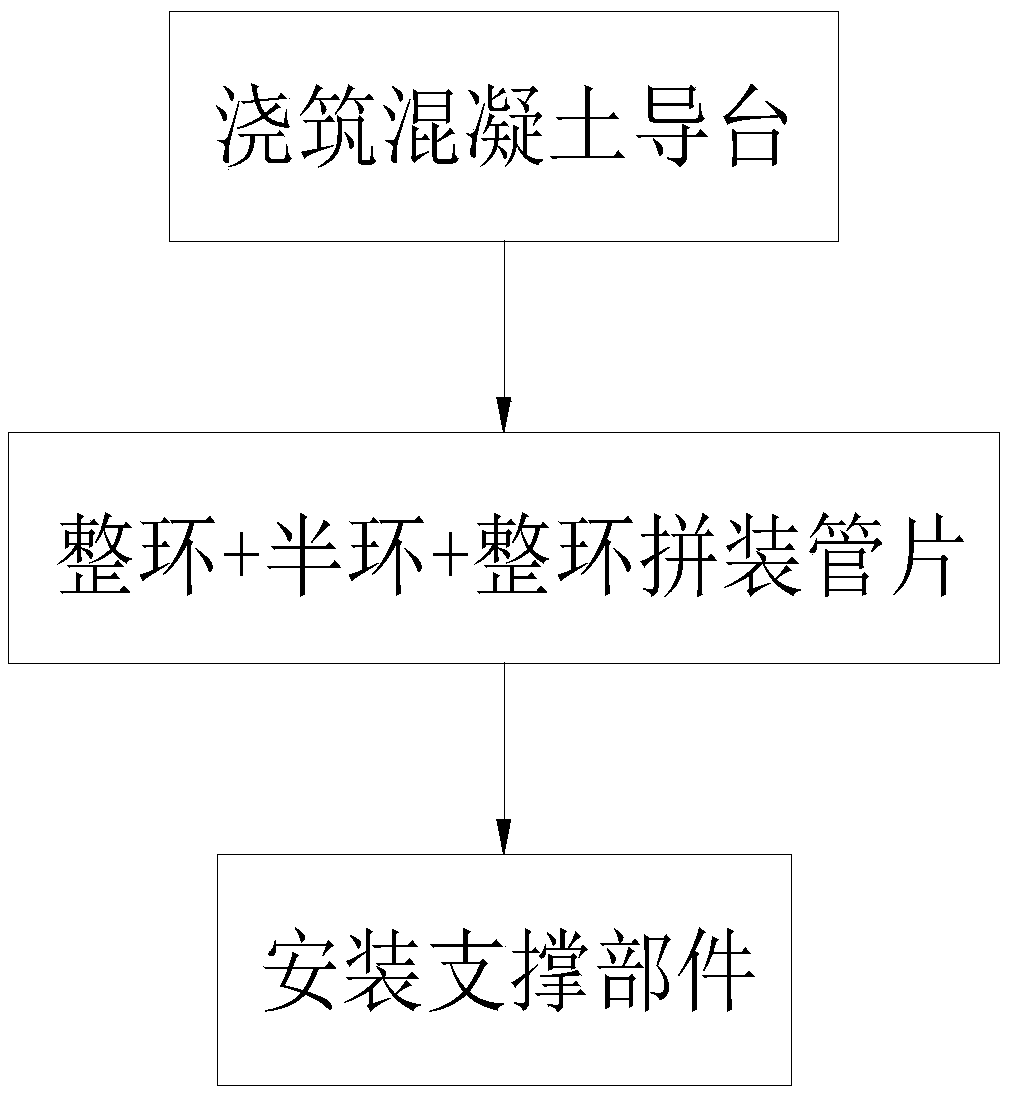

[0031] The construction method of the shield machine passing through the well according to the present invention, such as figure 1 As shown, the construction method includes the following steps:

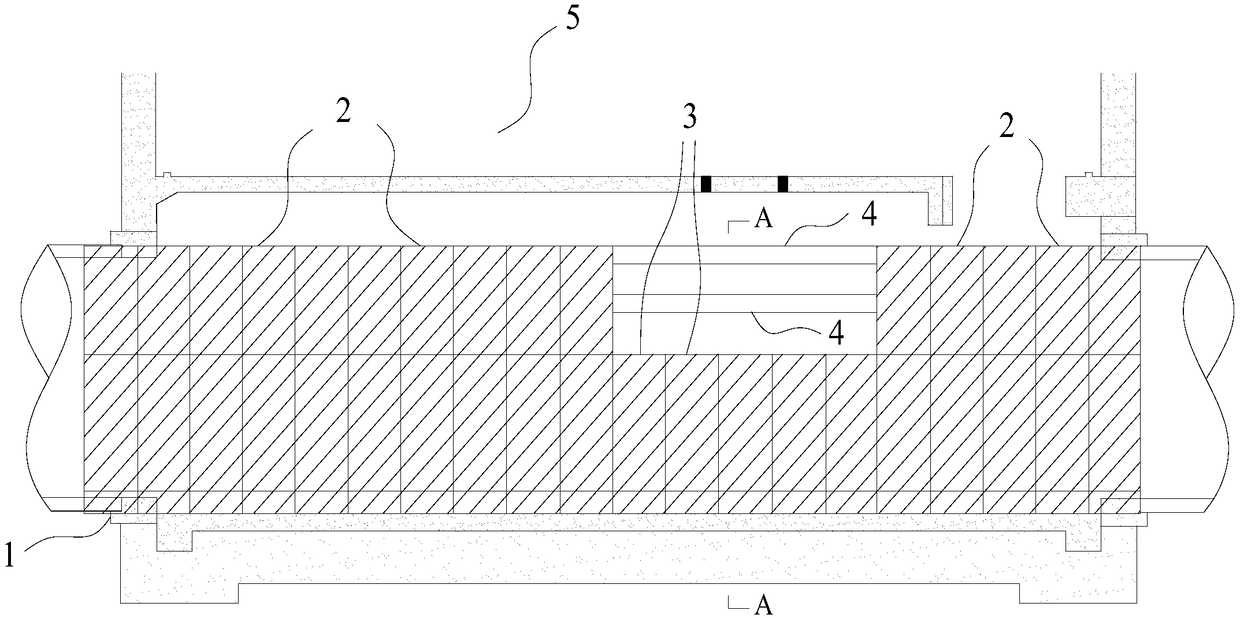

[0032] Step 1. Construct a concrete guide platform 1 on the bottom plate of the intermediate air shaft 5, and install a shield machine track on the concrete guide platform 1;

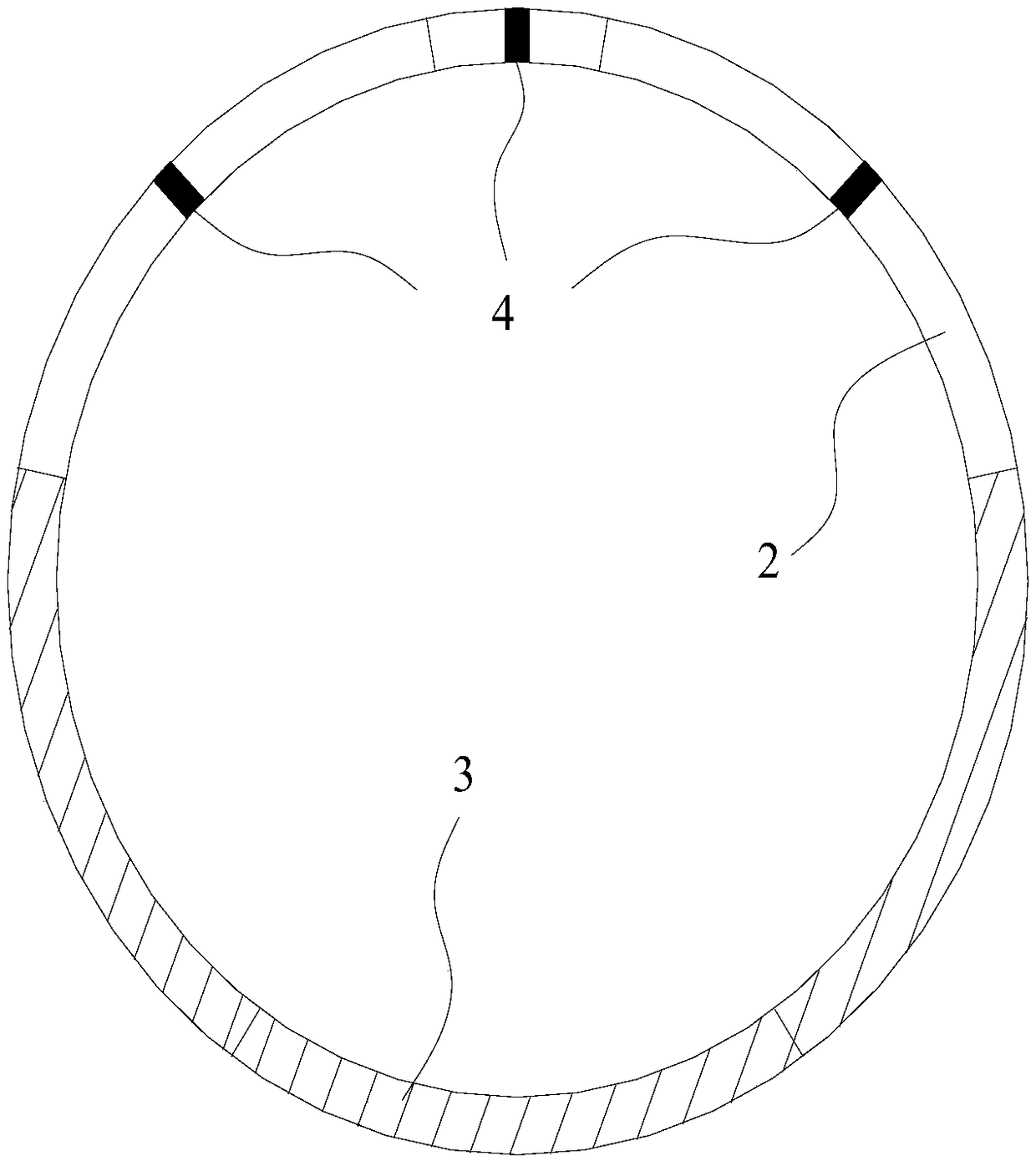

[0033] Step 2. After the shield body of the shield machine enters the middle air shaft 5, a number of whole-ring segments 2 are continuously assembled along the tunneling direction, and then a number of half-ring segments 3 are continuously assembled, and then a number of whole-ring segments 3 are continuously assembled. Ring tube piece 2;

[0034] Step 3. The shield machine reaches the second starting end, and a support member 4 is installed above a plurality of the half-ring segments 3, and both ends of the support member 4 are respectively installed on the plurality of the half-ring tubes On the two adjacent full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com