A Design Optimization Method of Centrifugal Fan

A technology of centrifugal fan and optimization method, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., and can solve problems such as inefficiency, excess, and high research and development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

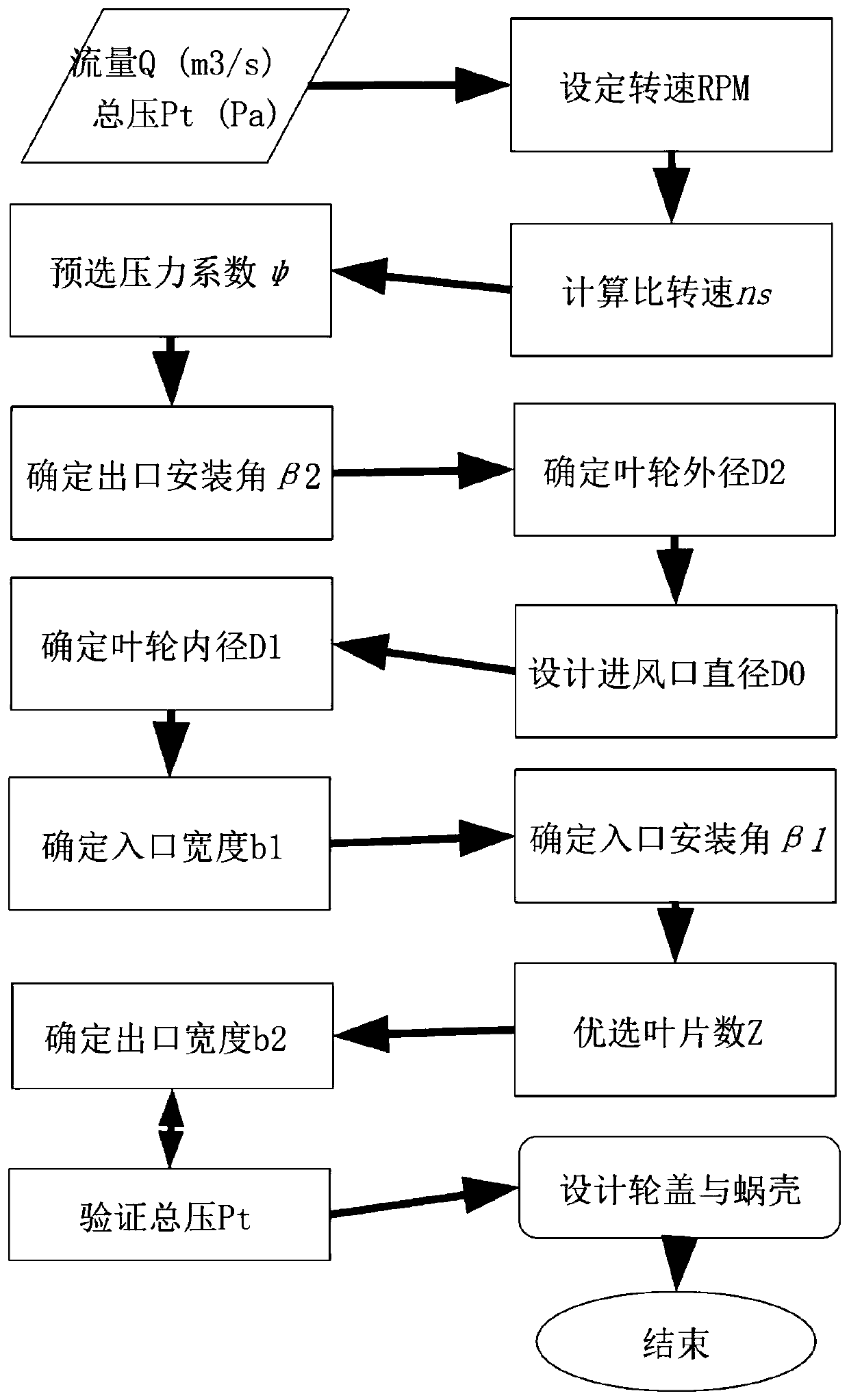

[0081] Embodiment one ( figure 2 )

[0082] figure 2 It is a flow chart showing the design of the universal centrifugal fan involved in Embodiment 1 of the present invention.

[0083] Such as figure 2 As shown, the specific steps of the general centrifugal fan design process are as follows:

[0084] Step 1, determine the design flow Q of the centrifugal fan n (m 3 / s) and design total pressure P n (Pa);

[0085] Step 2, set the speed RPM;

[0086] Step 3, calculate the specific speed ns;

[0087] Step 4, pre-select the pressure coefficient ψ;

[0088] Step 5, determine the outlet installation angle β2;

[0089] Step 6, determine the impeller outer diameter D2;

[0090] Step 7, design the air inlet diameter D0;

[0091] Step 8, determine the inner diameter D1 of the impeller;

[0092] Step 9, determine the entrance width b1;

[0093] Step 10, determine the inlet installation angle β1;

[0094] Step 11, preferred blade number Z;

[0095] Step 12, determine the...

Embodiment 2

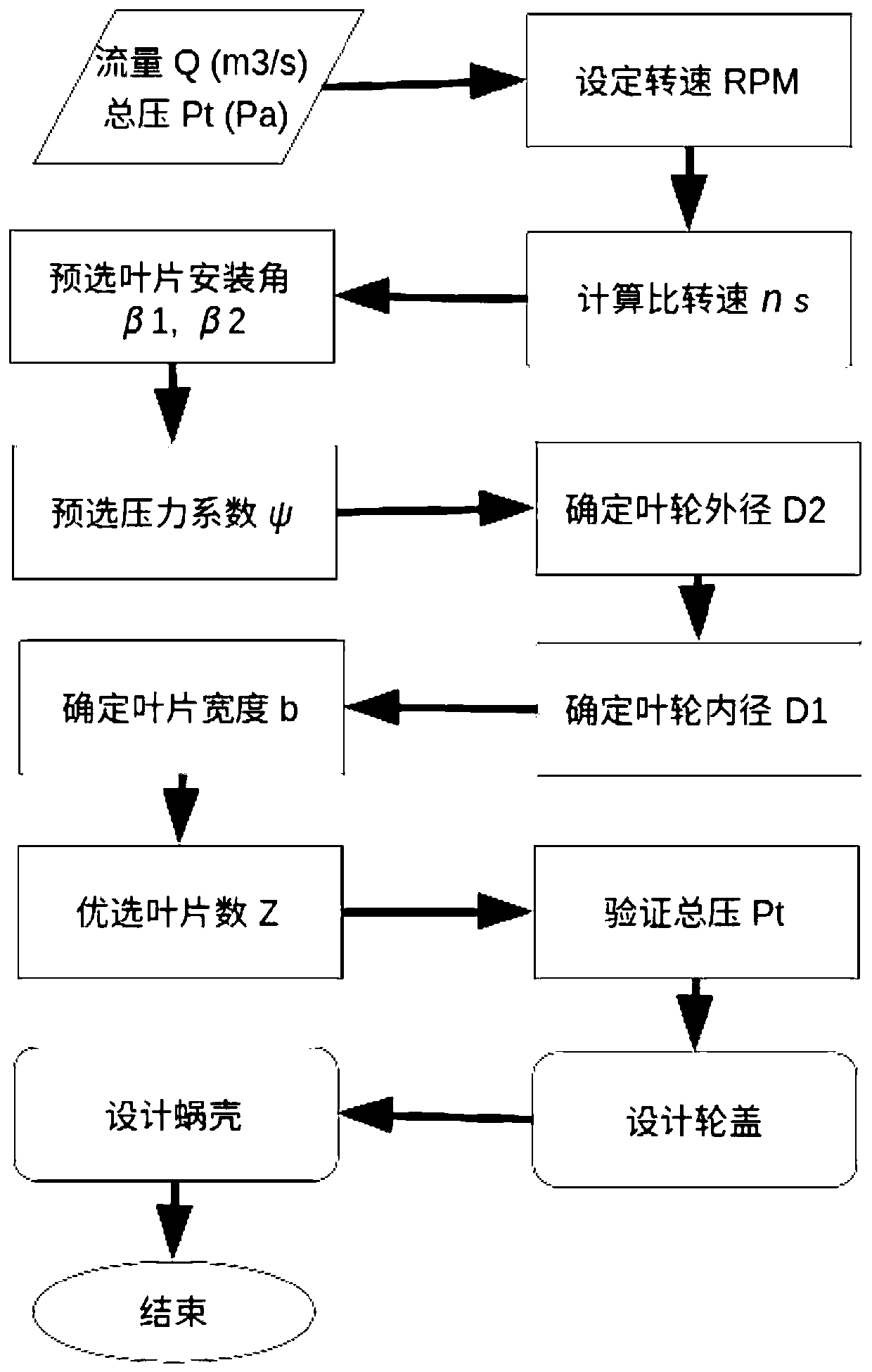

[0099] Embodiment two ( image 3 )

[0100] image 3 It is a flow chart showing the design of the multi-blade centrifugal fan involved in the second embodiment of the present invention.

[0101] The aerodynamic model of the multi-blade centrifugal fan is different from that of a common fan, and the design process described in Embodiment 1 cannot be used. Its feasible design process is as follows: image 3 As shown, the specific steps are as follows:

[0102] Step 1, determine the design flow Q of the centrifugal fan n (m 3 / s) and design total pressure P n (Pa);

[0103] Step 2, set the speed RPM;

[0104] Step 3, calculate the specific speed ns;

[0105] Step 4, preselect blade installation angles β1 and β2;

[0106] Step 5, pre-select the pressure coefficient ψ;

[0107] Step 6, determine the impeller outer diameter D2;

[0108] Step 7, determine the inner diameter D1 of the impeller;

[0109] Step 8, determine blade width b;

[0110] Step 9, preferred blade nu...

Embodiment 3

[0115] Embodiment three ( Figure 4 )

[0116] Figure 4 It is a flow chart showing the design of adjusting the outlet width of centrifugal fan blades of the present invention.

[0117] For non-equal width blades, adjusting the outlet width can change the outlet pressure of the centrifugal fan impeller. Using the steepest descent method, generally satisfactory results can be obtained. The gradient information used at this time is:

[0118]

[0119] For blades of equal width, the width is defined as b=b1=b2, and the gradient information is defined as:

[0120]

[0121] Its feasible design process is as follows: Figure 4 As shown, the specific steps are as follows:

[0122] Step 1, determine the design flow Q of the centrifugal fan n (m 3 / s) and design total pressure P n (Pa);

[0123] Step 2, set the speed RPM;

[0124] Step 3, preselect blade installation angles β1 and β2;

[0125] Step 4, determine the outer diameter D2 of the impeller and the inner diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com