Heat dissipation type LED lamp strip

A technology of LED light strips and LED lights, which is applied in lighting and heating equipment, cooling/heating devices of lighting devices, semiconductor devices of light-emitting elements, etc., which can solve problems such as severe heat generation, premature aging of LED light sources, and small space for lamps and lanterns. Good cooling effect, simple structure, easy to assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

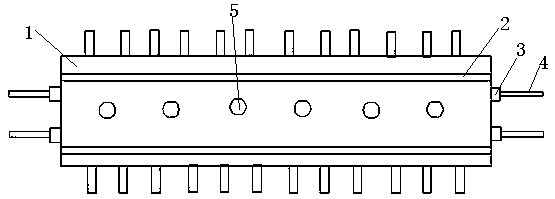

[0016] Such as figure 1 As shown, embodiments of the present invention include:

[0017] A heat-dissipating LED light bar, characterized in that it comprises: a bar-shaped LED light body 1, a line groove 2, a buckle mounting seat 3 and an LED light emitting unit 4; the line groove 2 is set on the LED light body 1 , the positive and negative lines are placed in the line groove 2; several buckle mounts 3 are installed on the four planes of the LED lamp body, and each buckle mount is correspondingly installed with the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap