LED zoom structure with backlight hood and diffusion film

A diffusion film and LED lamp bead technology, which is applied in the direction of semiconductor devices, light sources, electric light sources, etc. of light-emitting elements, can solve the problem of low-power LED details not being described too much, and achieve the improvement of focusing spot effect and optimize the backlight effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

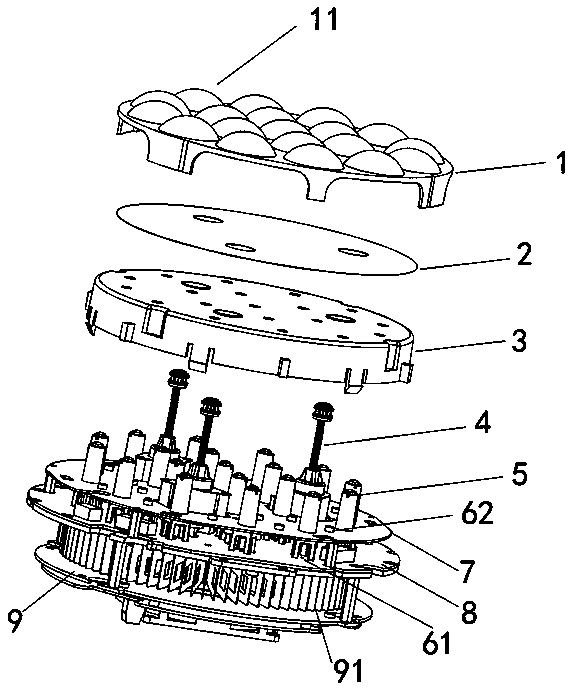

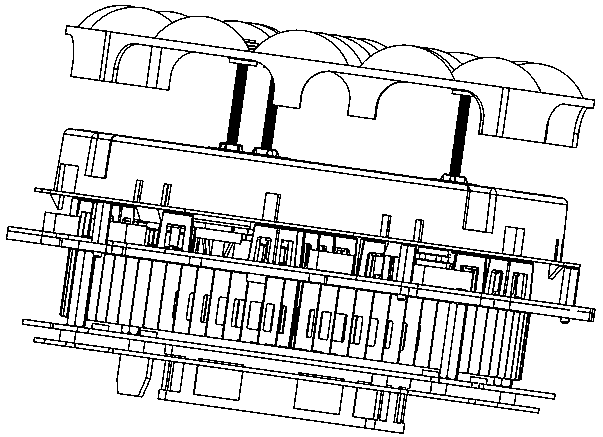

[0022] In this embodiment, as attached figure 1 and 2 As shown, the LED zoom structure with a backlight cover and a diffusion film, from top to bottom, is a combined lens plate (1), a diffusion film (2), a backlight cover (3), a screw focus motor (4), Light guide (5) column, LED lamp bead P2 (62), aluminum substrate two (7), LED lamp bead P1 (61), aluminum substrate one (8), radiator (9).

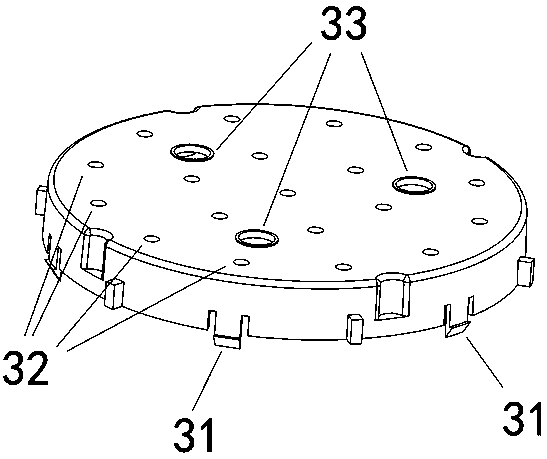

[0023] There are multiple convex lenses (11) on the combined lens plate (1) for spot magnification; the diffusion film (2) is circular and attached to the backlight cover (3), and there are 3 focusing motor holes on the surface; the backlight cover (3) It is in the shape of a circular cover, with multiple light holes (32) on the surface, and three focusing motor holes (33). There are multiple buckle angles (31) on the lower edge of the backlight cover (3), Buckle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com