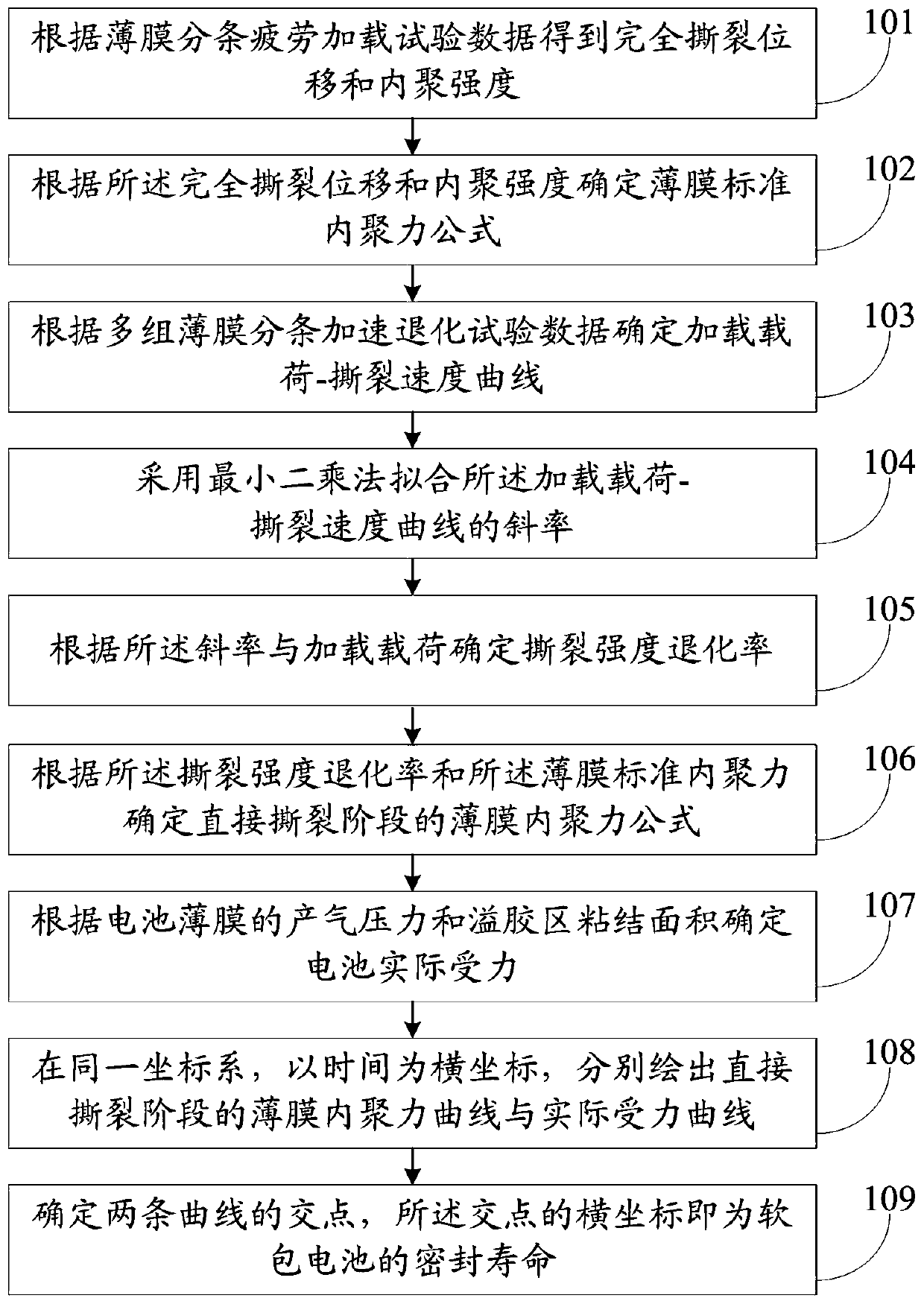

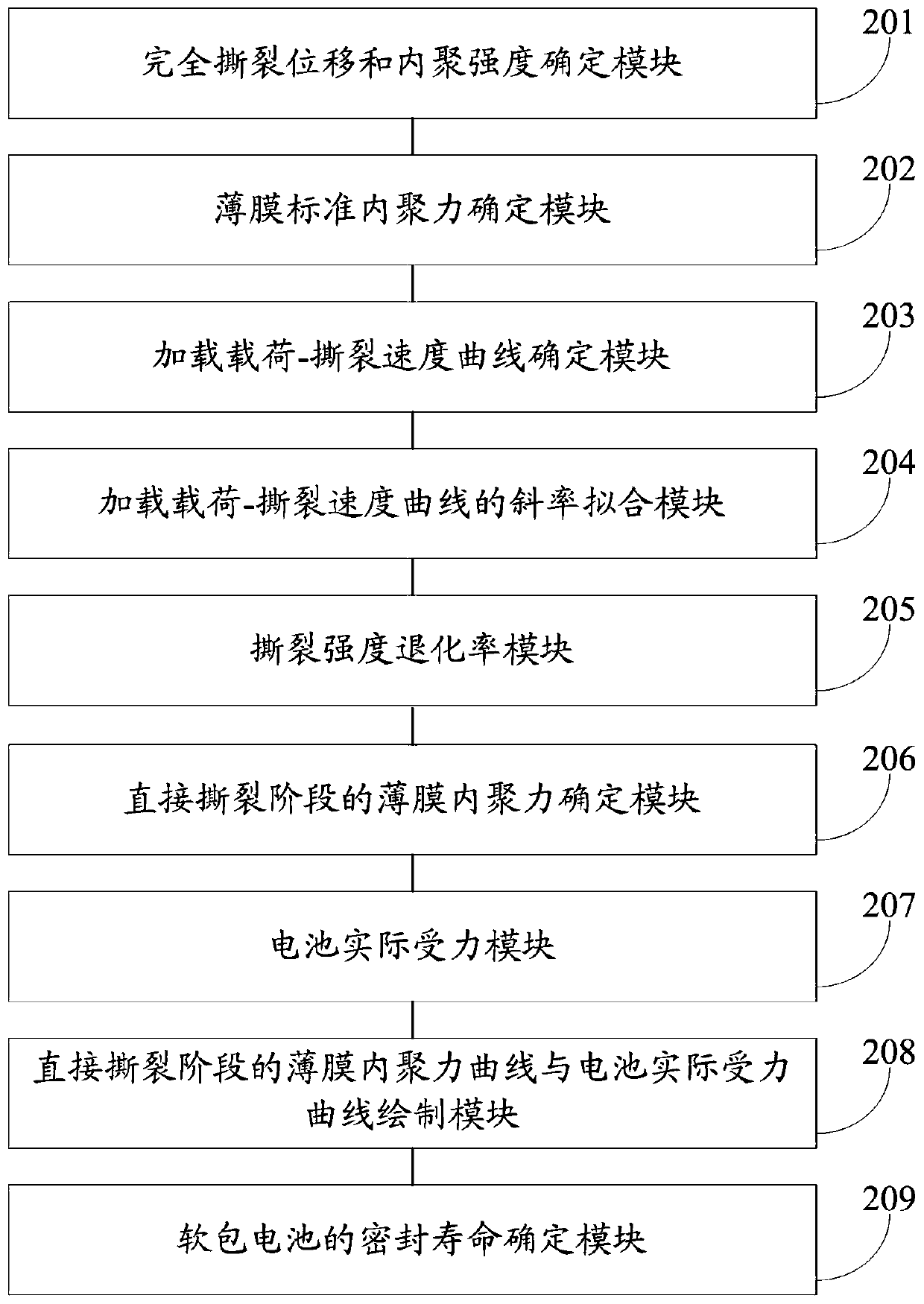

A method and system for predicting the sealing life of a pouch battery

A technology of sealed life and pouch battery, which is applied in the direction of measuring devices, instruments, and mechanical devices, etc., can solve the problem of slow tearing of the sealing edge, and achieve a high degree of self-learning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0117] The present invention uses experimental data to predict the sealing life of the soft pack battery as follows:

[0118] Step 1: Import direct tear test data: including the maximum tearing force τ max =45N, complete tearing displacement λ c =2.00mm;

[0119] Step 2: Substitute the experimental data into formula G c =eτ max λ c The cohesive strength is 244.66J / m2;

[0120] Step 3: G c , Λ c Into the formula Obtain the film standard cohesion model;

[0121] Step 4: By comparing with the test data, adjust the parameters to obtain a satisfactory model:

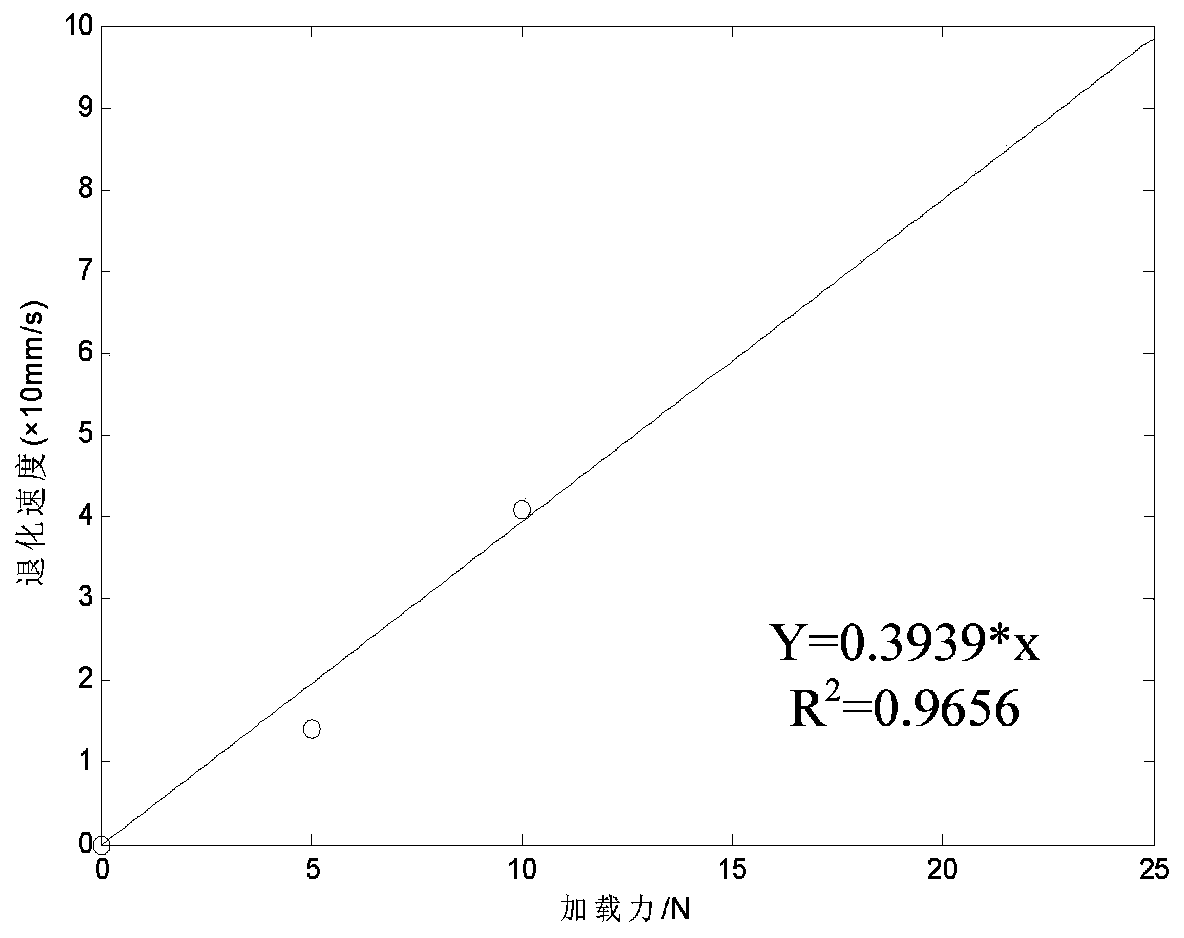

[0122] Step 5: Calculate the tear strength degradation rate:

[0123] Take the average of multiple groups of tearing displacement d to get: d 5N,20h =0.099, d 10N,20h = 0.31, d 15N,20h = 0.42, d 20N,20h = 0.60;

[0124] The fitting slope of the loading time-tearing displacement curve is the tearing velocity v′ corresponding to the tearing displacement, where v′ 5N =1.4×10 -6 mm / s, v′ 10N =4.1×10 -6 mm / s. Use the load as the absci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com