Profiled screen panel

A screen panel, special-shaped technology, applied in lighting and heating equipment, instruments, mechanical equipment, etc., can solve the problem of the width of the lower frame, and achieve the effect of reducing the width and increasing the proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

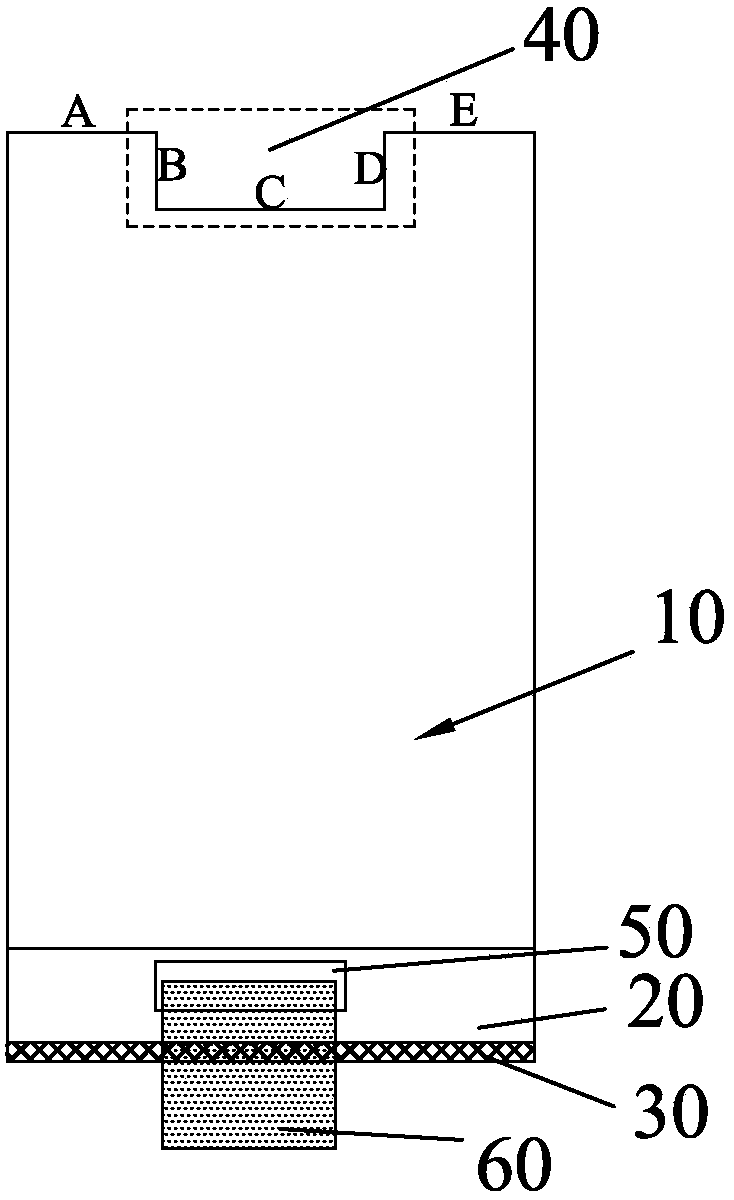

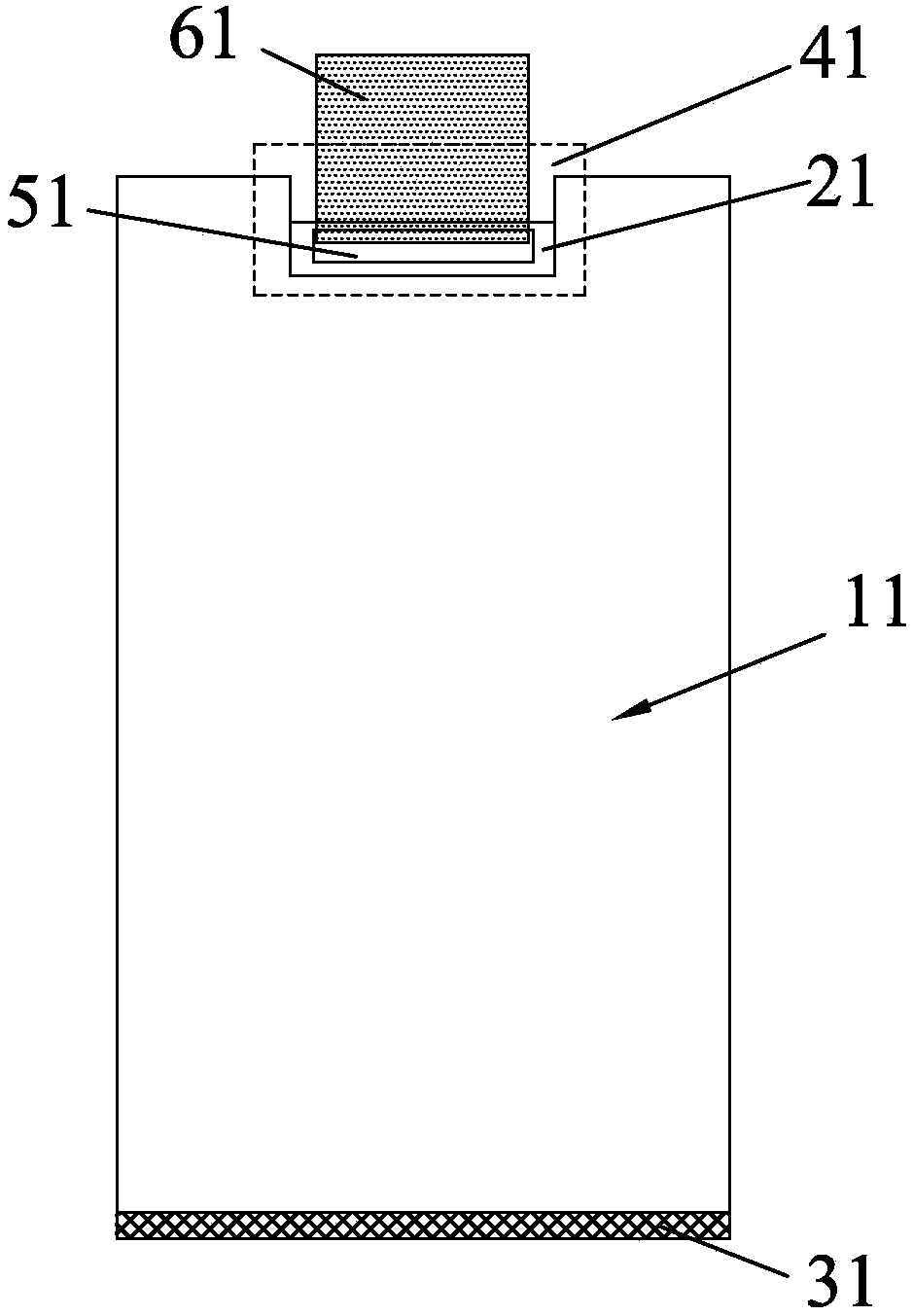

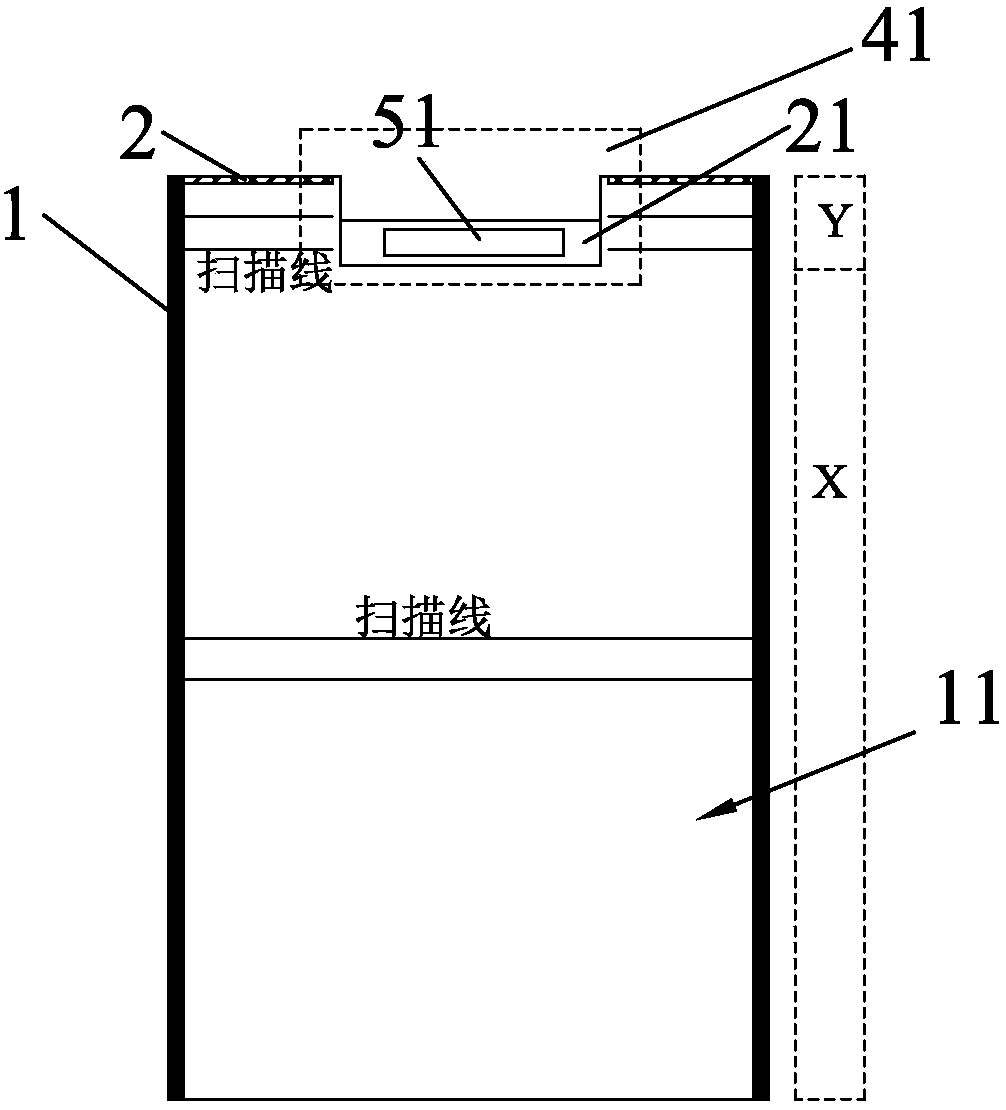

[0027] Based on the problems raised by the background technology, the present invention proposes a design to reduce the lower frame of the special-shaped screen panel and increase the screen ratio of the terminal application, that is, the pad area is set in the groove of the opening / opening position; further, glass can be used Chip-on-chip or chip-on-chip technology connects the pad area and the control circuit system (which may include driver chips, flexible circuit boards, and printed circuit boards); the flexible circuit board can be bent to the back of the panel; and the LED light bar of the backlight system can be Set on the opposite side or the same side as the opening / hole location.

[0028] see figure 2 , which is a schematic structural layout diagram of Embodiment 1 of the special-shaped screen panel of the present invention. The upper end of the panel 11 has a rectangular longitudinal groove 41 formed by an opening / hole design, and the rectangular pad area 21 is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com