Aero-engine online optimization and multivariable control design method based on model predictive control

An aero-engine, multi-variable control technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem that the real-time performance of the controller control system is difficult to take into account

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

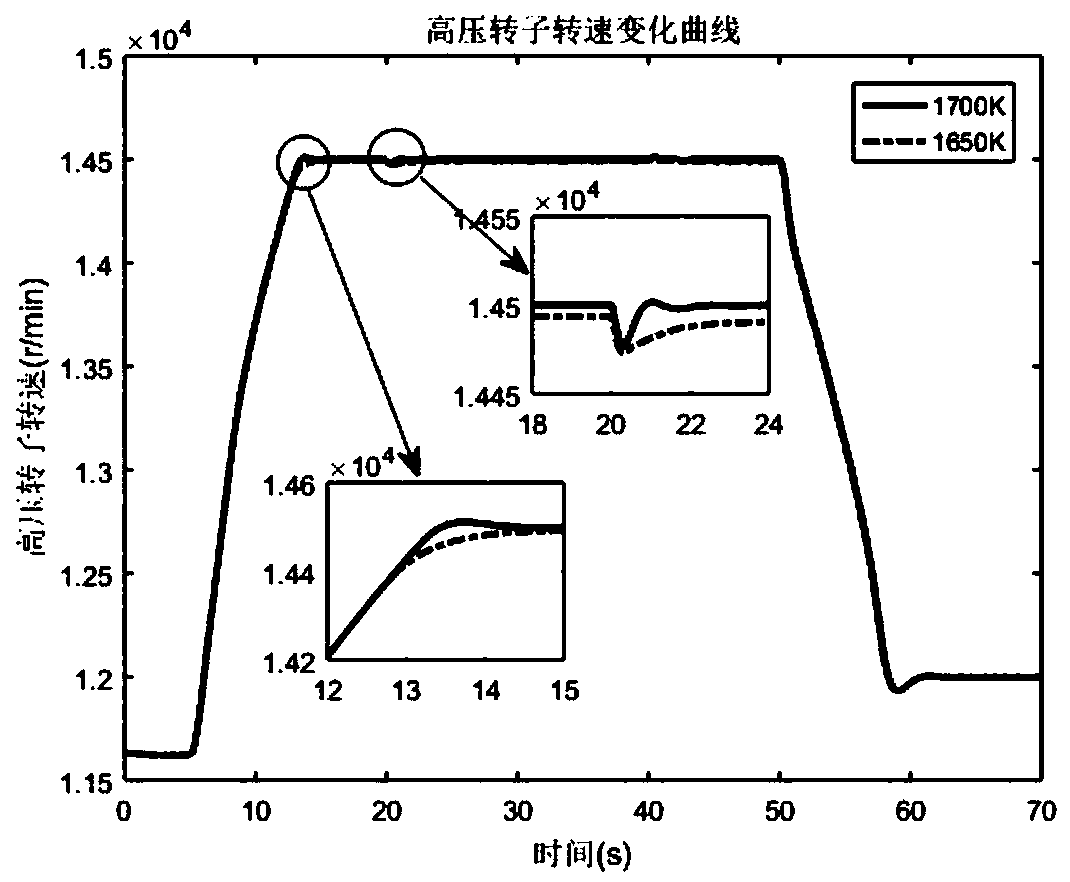

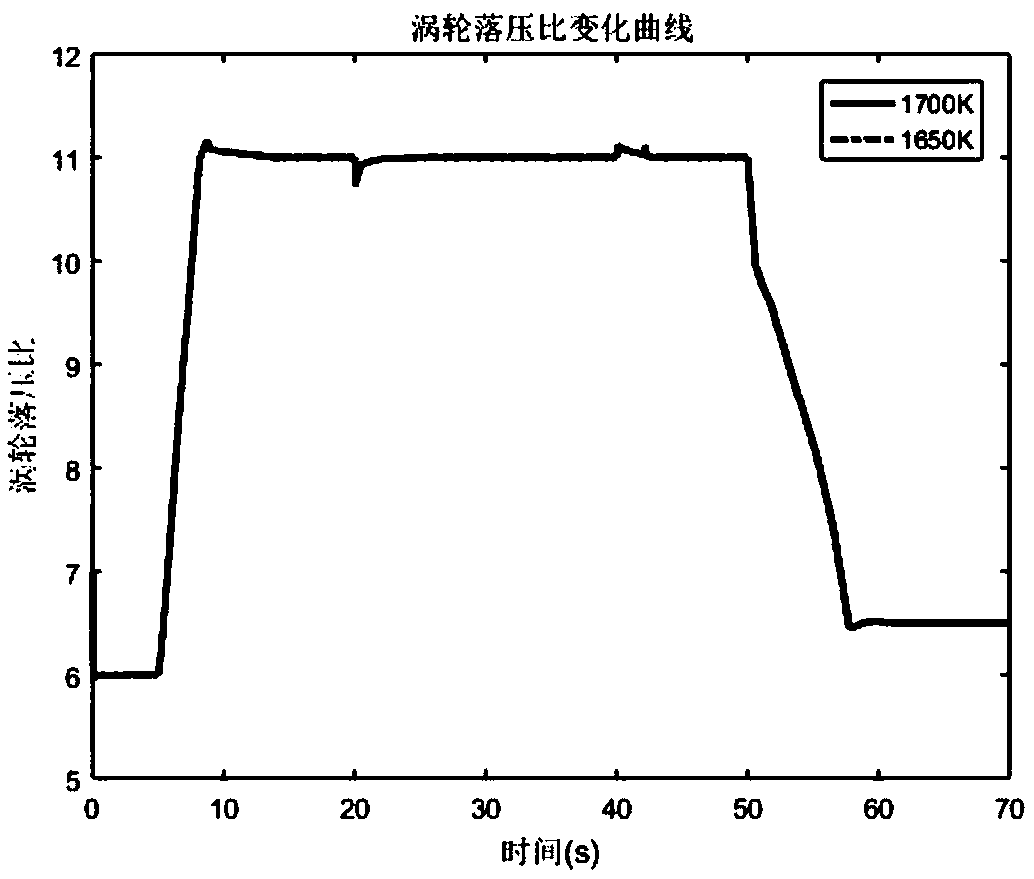

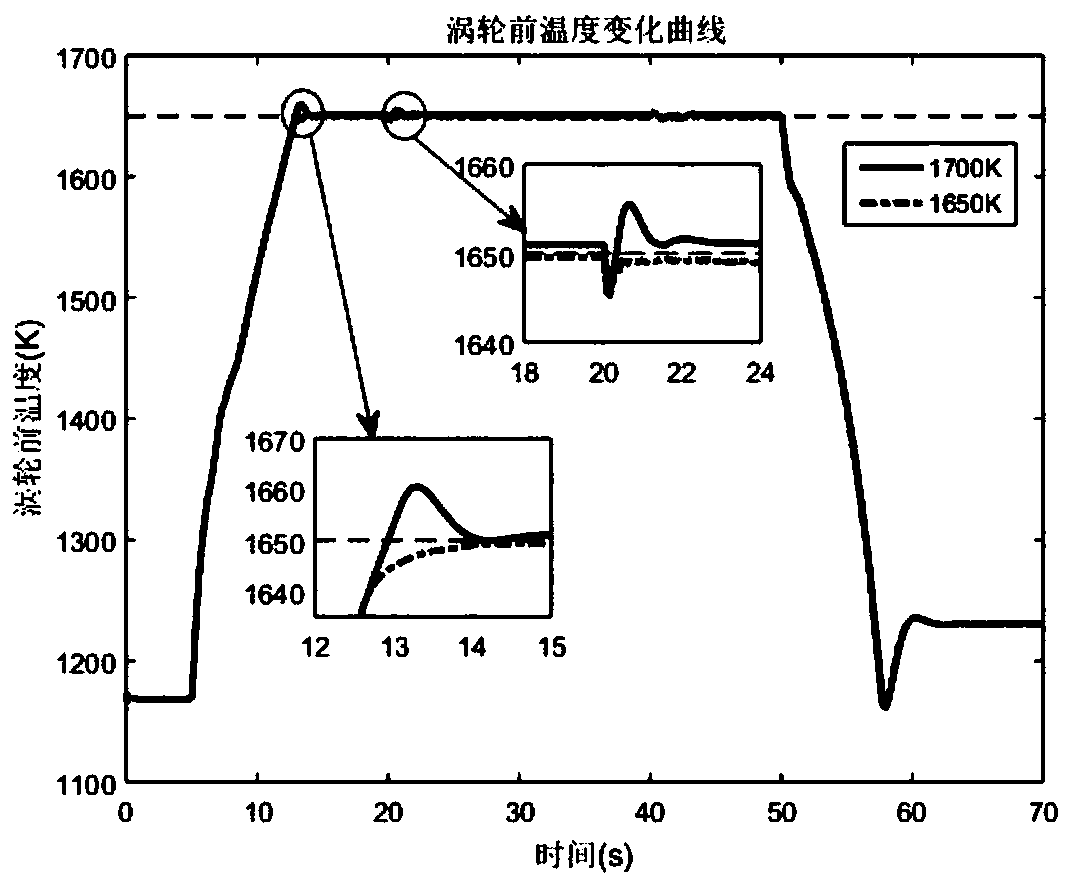

[0097] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0098] This embodiment is an online optimization and multivariable control design method for an aeroengine based on model prediction. The detailed design steps are as follows:

[0099] Step 1: Establish the aero-engine small deviation gain model with the current aero-engine actual input and external environmental parameters as the steady-state point; first obtain the steady-state point for calculating the linearized small-deviation model. In the present invention, the input quantity and environmental parameters at the last sampling moment of the engine are approximated as the steady state point to calculate the small deviation model at the current moment. The method of calculating the small deviation model of the engine near the steady state point is as follows.

[0100] During the working process of an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com