Accurate modeling and assembling method for involute worm gear and worm

A worm gear and assembly method technology, applied in the field of mechanical transmission parts, can solve problems such as error-prone, complex process, low efficiency, etc., and achieve the effects of accurate modeling, strong versatility, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present invention provides a technical solution: a precise modeling and assembling method of an involute worm gear, and the specific steps of the precise modeling and assembling method of an involute worm gear are as follows:

[0037] S1: Modeling of the worm gear,

[0038] 1) In the part design environment, create a three-dimensional basic entity of the worm gear blank;

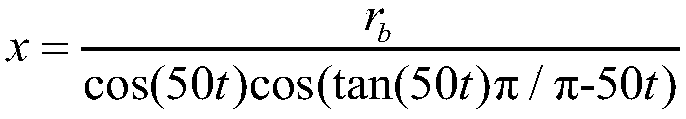

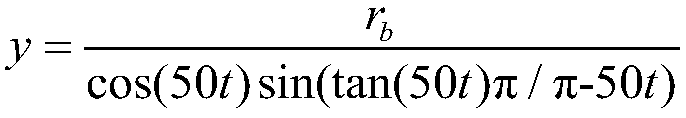

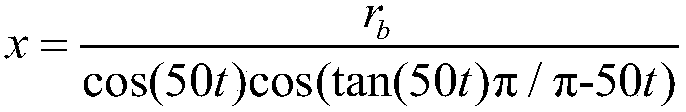

[0039] 2) In the environment of wire frame and surface design, a number of model points on the involute line are generated through the regular curve, and the corresponding worm gear involute curve is constructed by using the fourth-order cubic interpolation B-spline curve, and each point on the involute line The regular curve expression about the abscissa x and ordinate y is as follows:

[0040]

[0041]

[0042] where r b is the radius of the base circle, and 50 means that the selection range of the involute is 0°-50°;

[0043] 3) In the part design environment, after a series of operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com