Involute surface envelope ring surface worm and worm wheel tri-dimensional entity modelling method

A toroidal worm and three-dimensional solid technology, applied in 3D modeling, using manual input to modify/create images, image data processing, etc., to achieve the effect of wide application range, strong versatility, and accurate modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

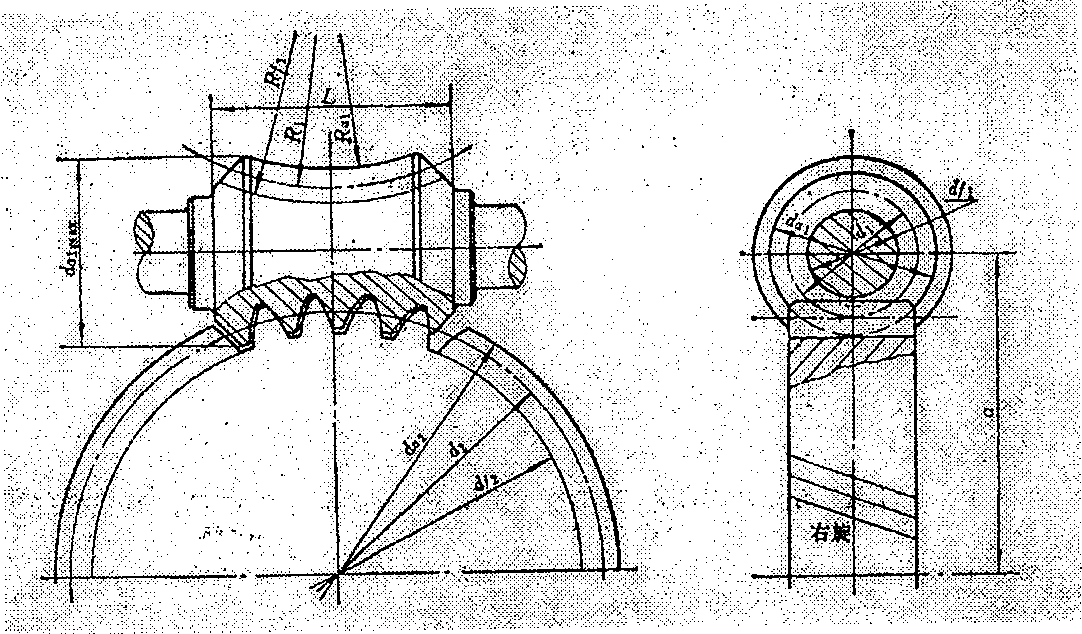

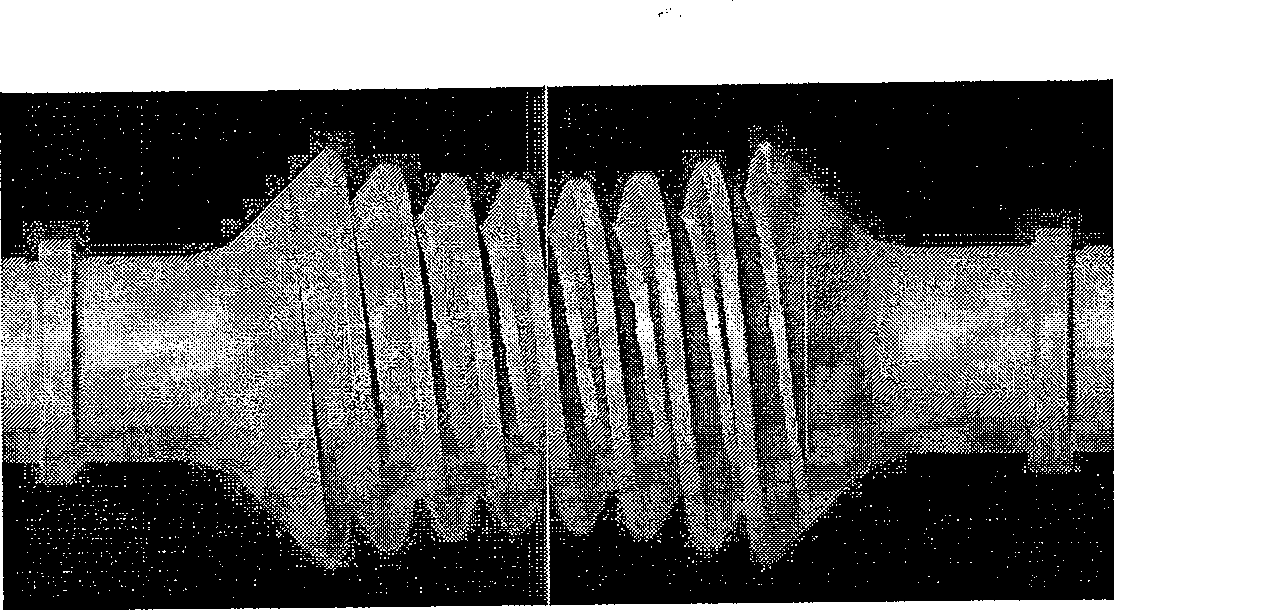

[0054] figure 1 It is a reference diagram for the design of involute enveloping toroidal worms, figure 2 It is the three-dimensional solid modeling of the involute enveloping toroidal worm completed according to the design reference drawing. Its main parameters are as follows: worm head number z1=2, worm axial modulus m=6.033, worm pitch circle diameter d1=89.753, worm throat helix angle r=8.1718, axial section pressure angle α=20.10140, min Degree circle helix angle β=6.00030, number of worm gear teeth surrounded by worm z'=7, number of worm gear teeth z2=68, diameter of worm gear pitch circle d2=410.244, transmission center distance a=249.9985.

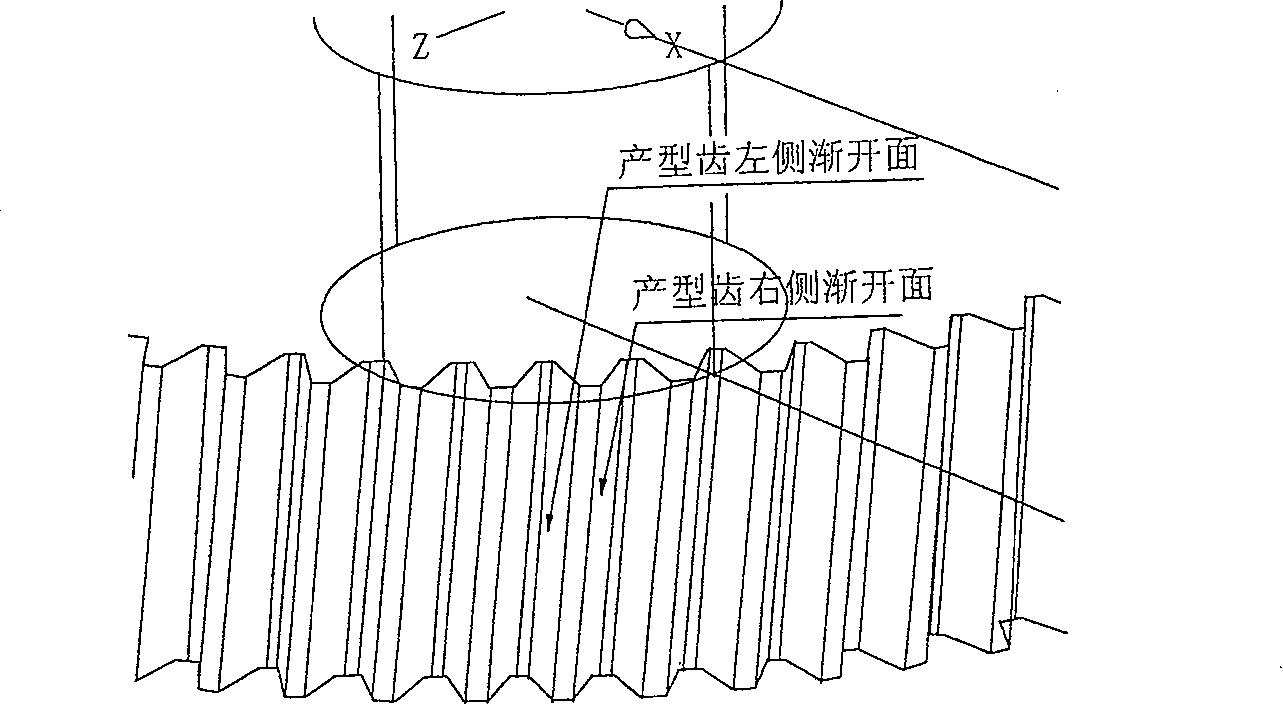

[0055] Before constructing the three-dimensional entity of the involute enveloping toroidal worm, in order to better understand the present invention, the characteristics of the enveloping involute surface are first analyzed:

[0056] The teeth of the involute surface primary enveloping toroidal worm can be straight involute gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com