Group maintenance decision-making method based on system-level life service information

A system-level, maintenance strategy technology, applied in the direction of instruments, data processing applications, forecasting, etc., to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

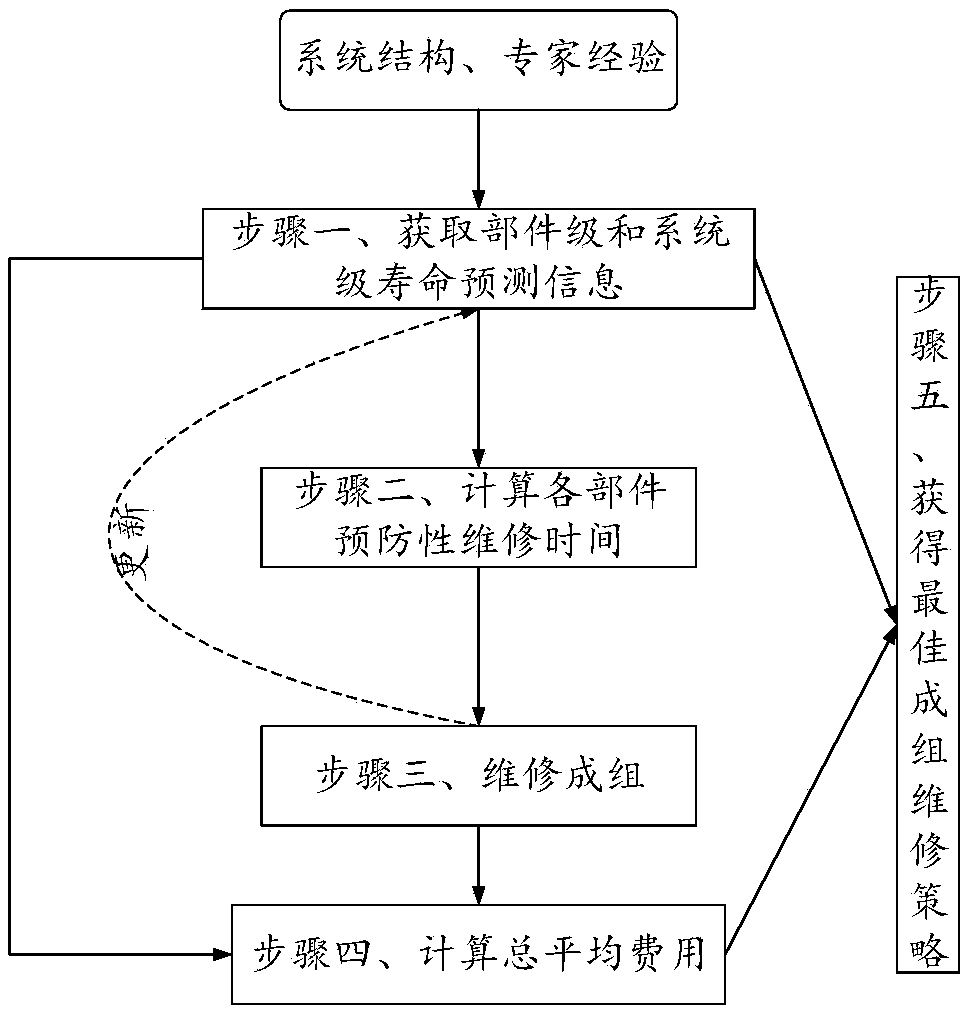

Method used

Image

Examples

Embodiment example

[0053] (1) Overview of simulation examples

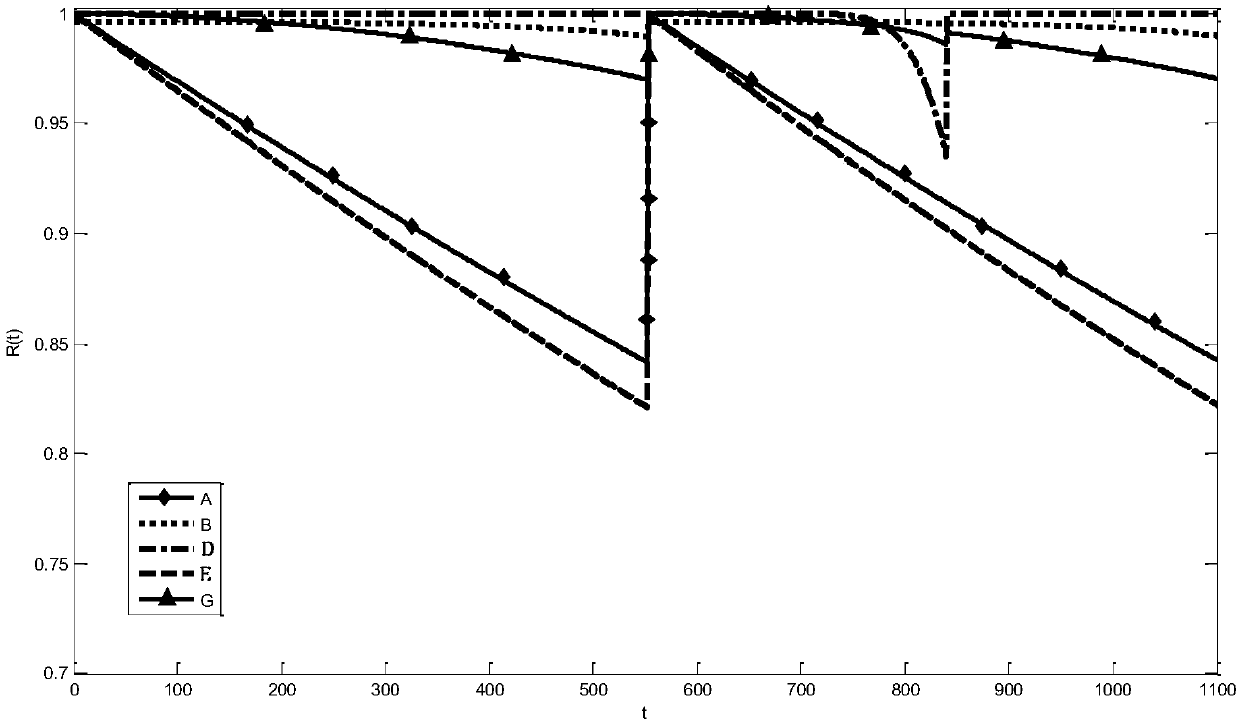

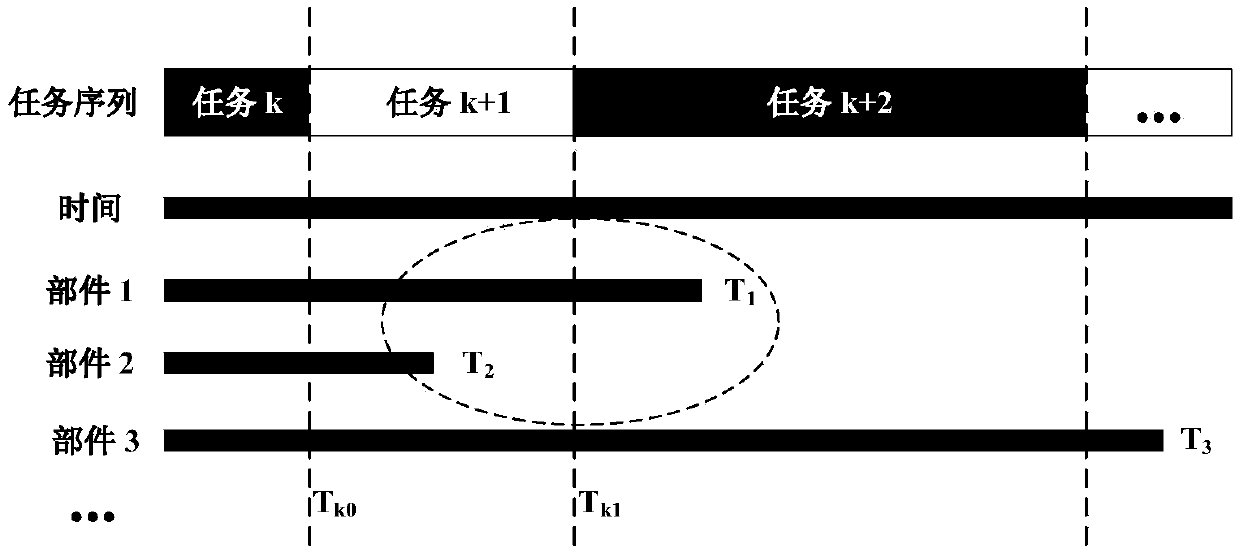

[0054] Suppose a product G has image 3 The functional structures shown are related, in which subsystems C and F are connected in parallel, and A, B, D, and E are connected in series respectively. The product has two mission downtimes at 552h and 840h, that is, two maintenance opportunities, and is decommissioned after the working time reaches 1100h. The failure modes and associated costs of components A, B, E, and D are shown in the table below.

[0055] Table 1 Failure modes and related costs of each component

[0056]

[0057] (2) Model construction

[0058] According to the system reliability block diagram, the relationship between components can be established. It can be known that components A, B, D, and E are root nodes, subsystem CF is an intermediate node, and system G is a leaf node. Based on the series-parallel relationship between components and expert experience, the BN model can be established as Figure 4 show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com