A granulated tea

A technology of granular tea and tea leaves, which is applied in tea treatment before extraction, etc., can solve the problems of inconvenient use, easy mildew and deterioration, and affecting drinking desire, etc., and achieves less mildew, more brewing times, and little difference in taste before and after Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a kind of preparation method of above-mentioned granular tea, comprises the following steps:

[0040] A) drying and pulverizing the tea leaves to obtain tea powder;

[0041] Under airtight conditions, the tea powder is heated to 172-290°C and kept for 90-360s to obtain tea gum in a molten state;

[0042] B) In step A), the tea powder after extracting the tea gel is molded to obtain the tea ball core;

[0043] C) Spraying the tea gum in the molten state on the surface of the tea ball core, and cooling to obtain granular tea.

[0044] The present invention selects one or more of high-quality green tea, black tea and black tea as raw materials, and pulverizes after drying to obtain tea powder;

[0045] Wherein, the crushing fineness of the tea powder is preferably 10-20 mesh. The moisture content in the dried tea leaves is 8%-11.5%, preferably 9%-11%.

[0046] Next, under airtight conditions, the tea powder is heated to 172-290°C and k...

Embodiment 1

[0056] The green tea is dried until the moisture content is 9.2%, and then pulverized to 10-20 meshes to obtain tea powder.

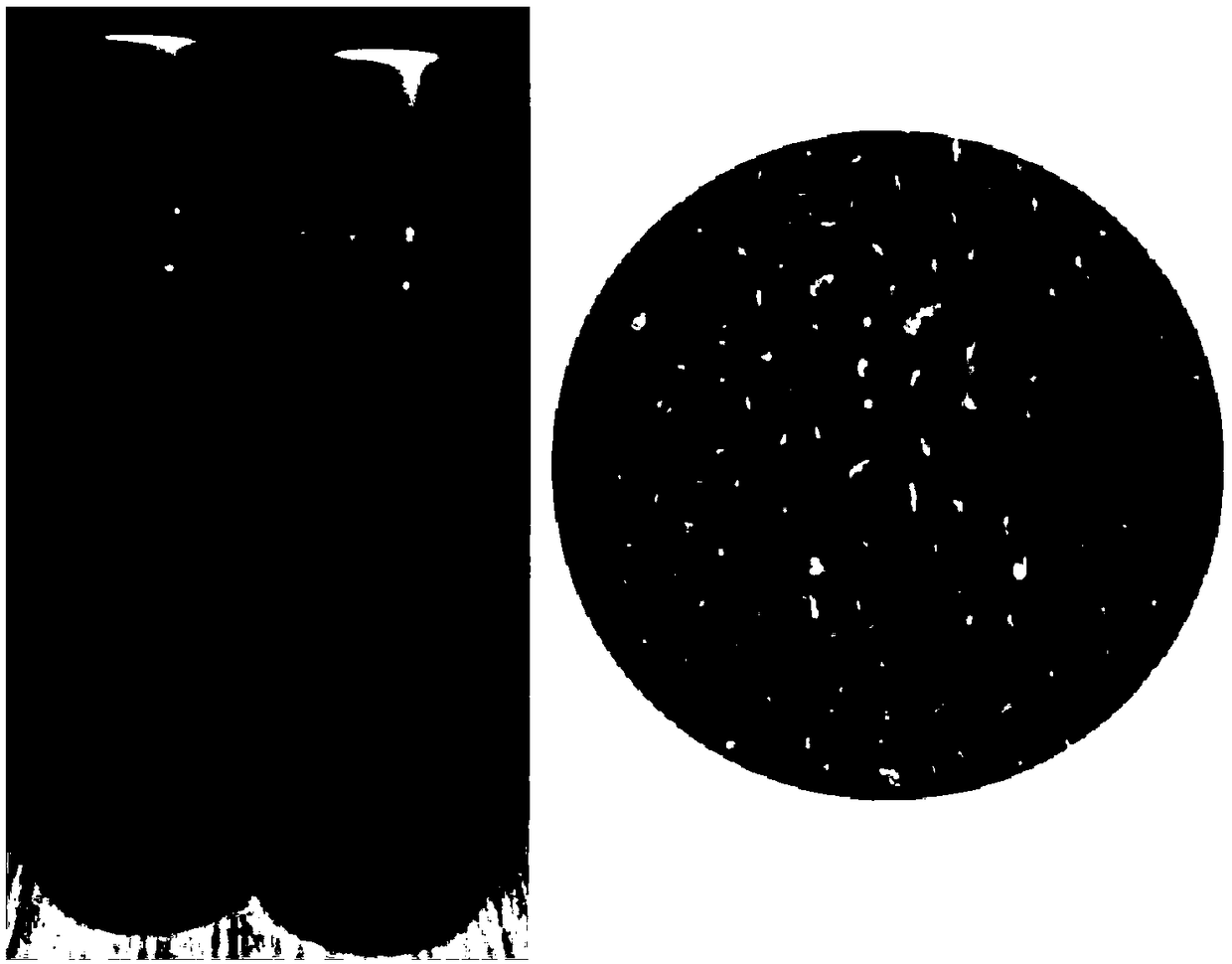

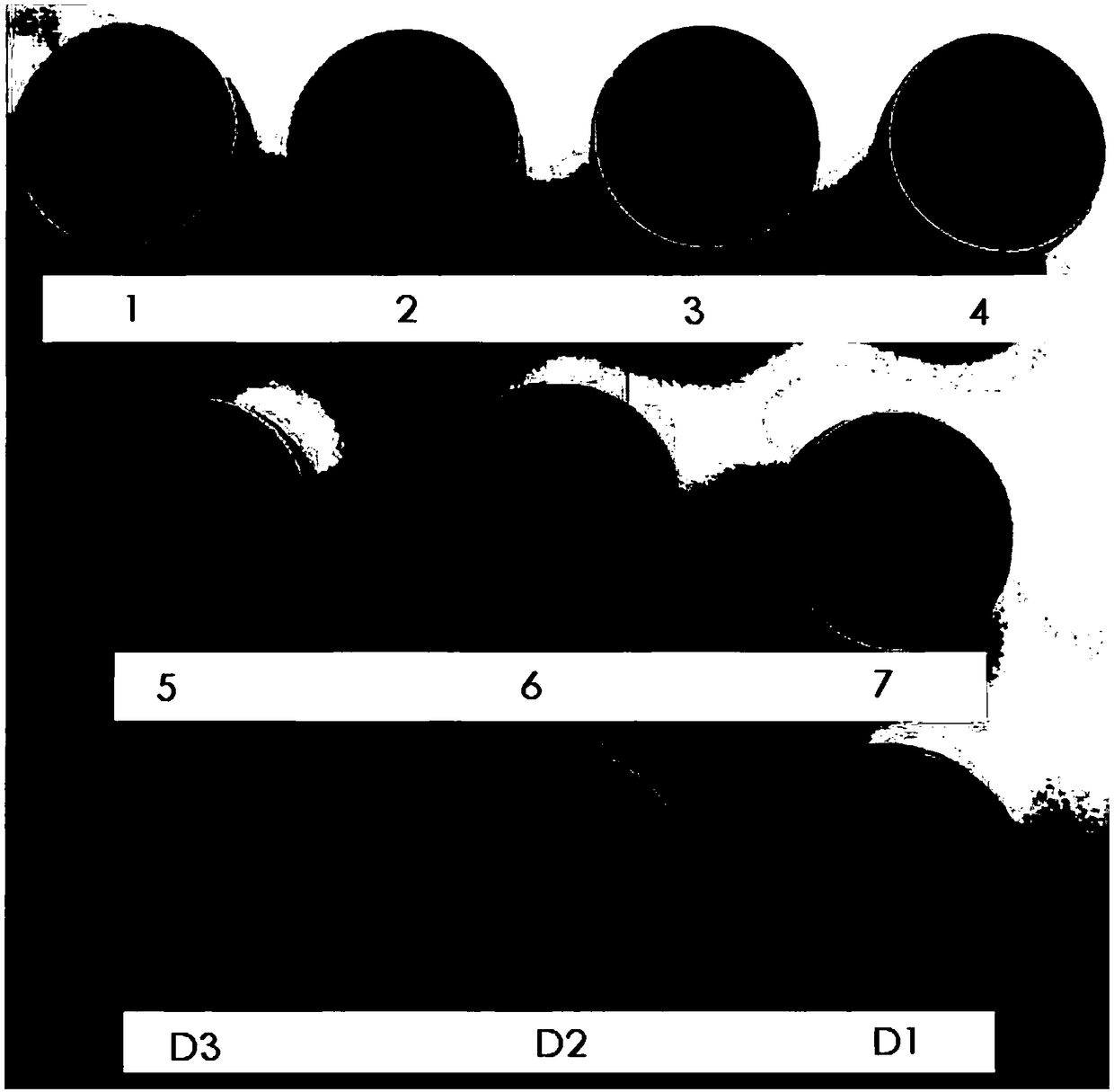

[0057] Under airtight conditions, the tea powder is heated to 183° C. and kept for 220 s to obtain tea gum in a molten state; the tea powder after extraction of tea gum is molded to obtain a tea ball core with a particle size of 2-3 mm. Under the condition of 286°C, 13340g of the tea gum in molten state was sprayed on the surface of 186660g of the tea ball core to form a tea gum layer with a thickness of 55-75μm, and after cooling, granular tea was obtained. see diagram 2-1 as well as Figure 2-2 , diagram 2-1 For the photo of the granular tea that embodiment 1 prepares, Figure 2-2 It is a photo of the granular tea prepared by the present invention and the tea leaves of the comparative example.

Embodiment 2

[0059] The black tea is dried until the moisture content is 7.7%, and then pulverized to 10-20 meshes to obtain tea powder.

[0060] Under airtight conditions, the tea powder is heated to 175° C. and kept for 210 s to obtain tea gum in a molten state; the tea powder after extraction of the tea gum is molded to obtain a tea ball core with a particle size of 2-3.5 mm. Under the condition of 285°C, 12890g of the molten tea gum was sprayed on the surface of 187110g of the tea ball core to form a tea gum layer with a thickness of 50-70μm, and after cooling, granular tea was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com