Automatic waterproof zipper laminator

An automatic waterproof and film lamination machine technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of high labor cost, low efficiency, complicated waterproof zipper lamination process, etc., and achieve the effect of saving labor and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

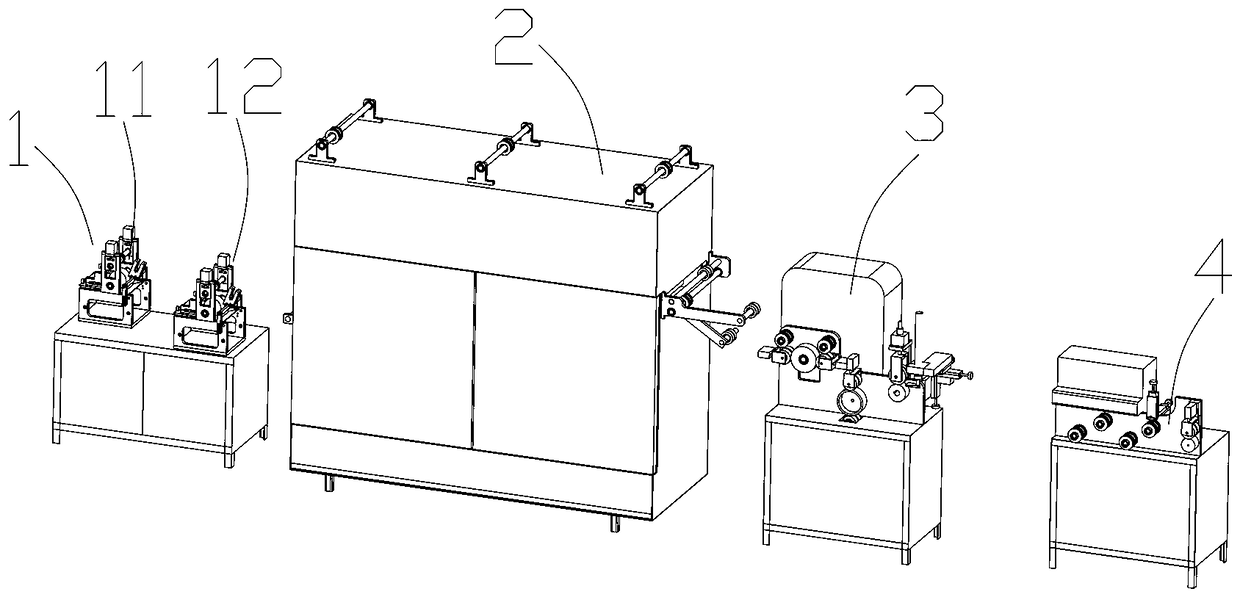

[0028] refer to Figure 1 to Figure 8 , the automatic waterproof zipper film laminating machine of the present invention includes a gluing device 1 for gluing the zipper cloth tape, a drying device 2 for drying the glue on the zipper cloth tape into an adhesive film, and is used for bonding the adhesive film to the adhesive film. Laminating device 3 for pressing and bonding the cloth tape, and splitting device 4 for slit the film;

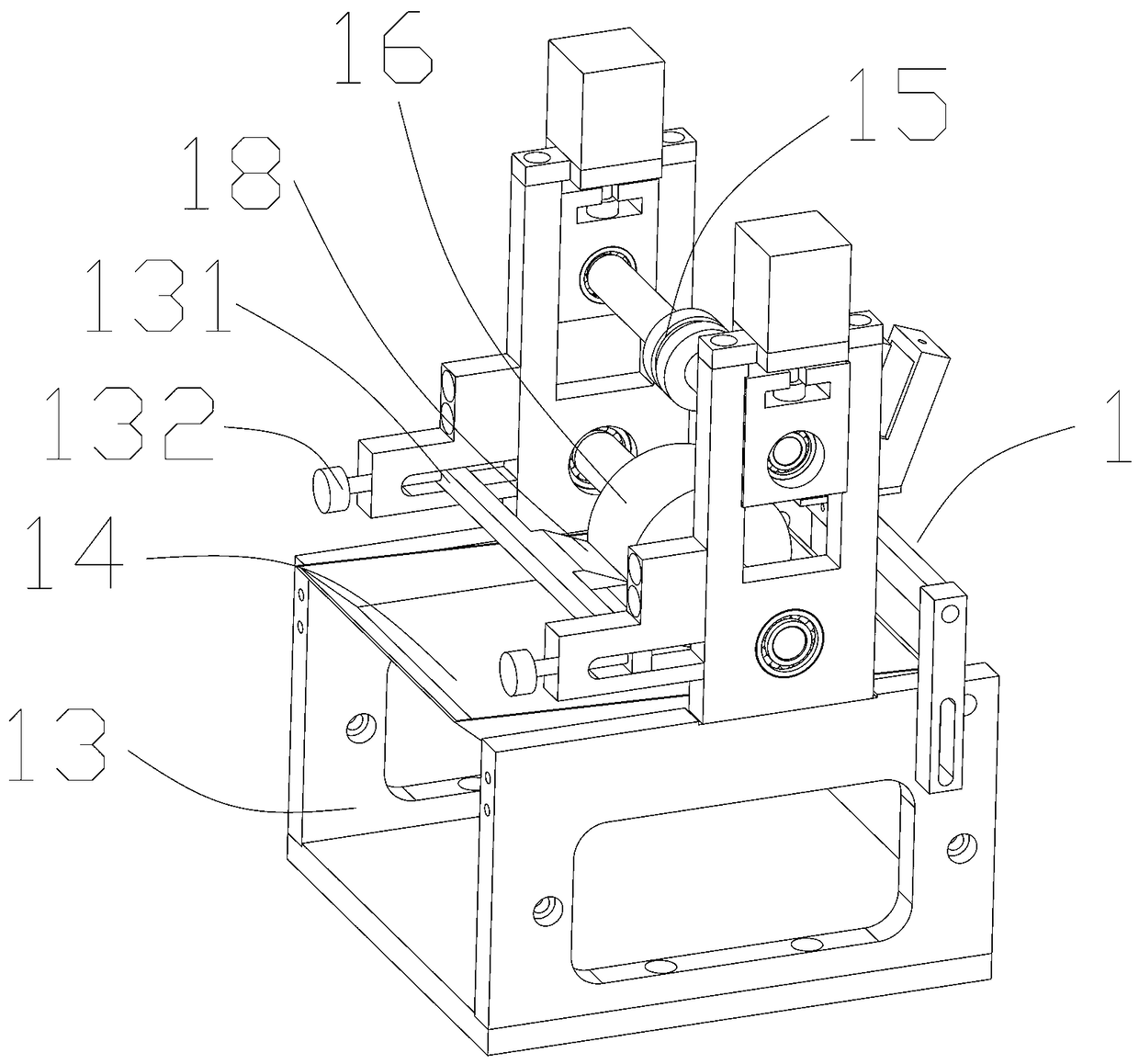

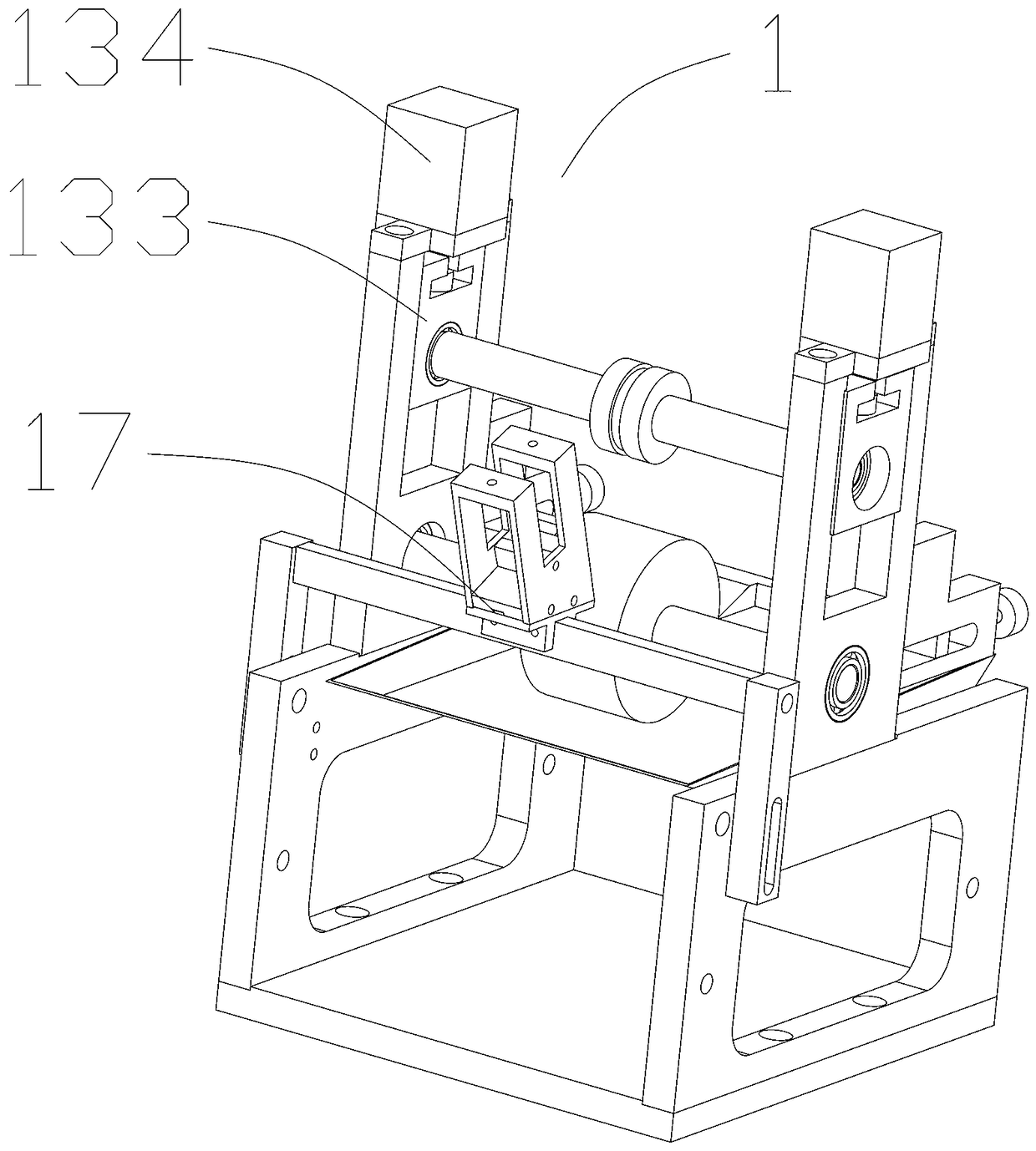

[0029] The gluing device 1 is provided with two respectively the first gluing device 11 and the second gluing device 12; in the present embodiment, the first gluing device 11 and the second gluing device 12 are arranged on the gluing base, The gluing device 1 includes a gluing bracket 13, a glue storage tank 14 arranged on the gluing bracket, a gluing guide wheel 15 and a gluing wheel 16 for pressing the zipper cloth tape ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap