Interior iron chip slag removal machine for complex parts

A technology for parts and slag removers, applied in the field of machining, can solve the problems of too much cleaning fluid or cutting fluid, hidden dangers, slippery ground and other problems, and achieve the effect of low noise and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

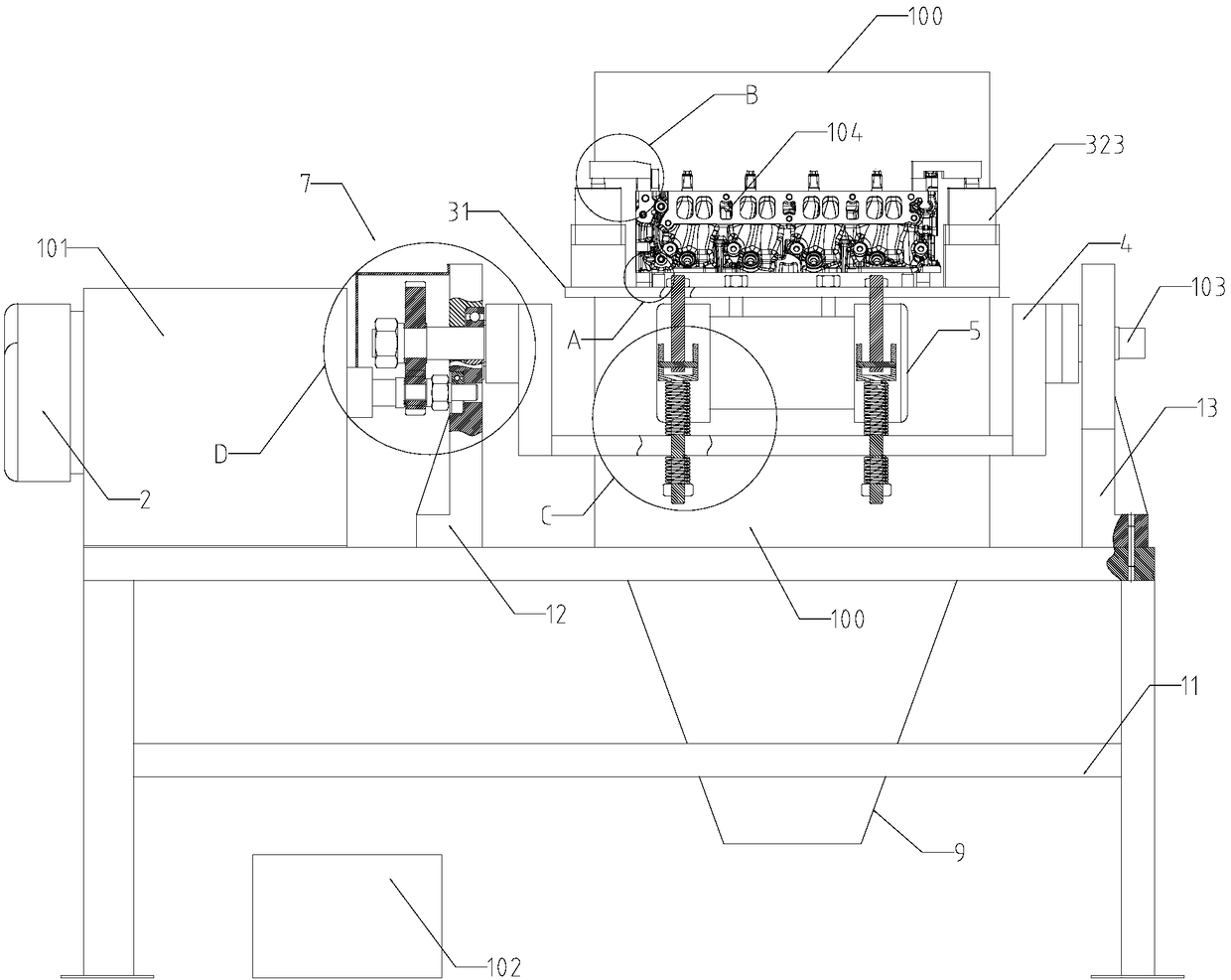

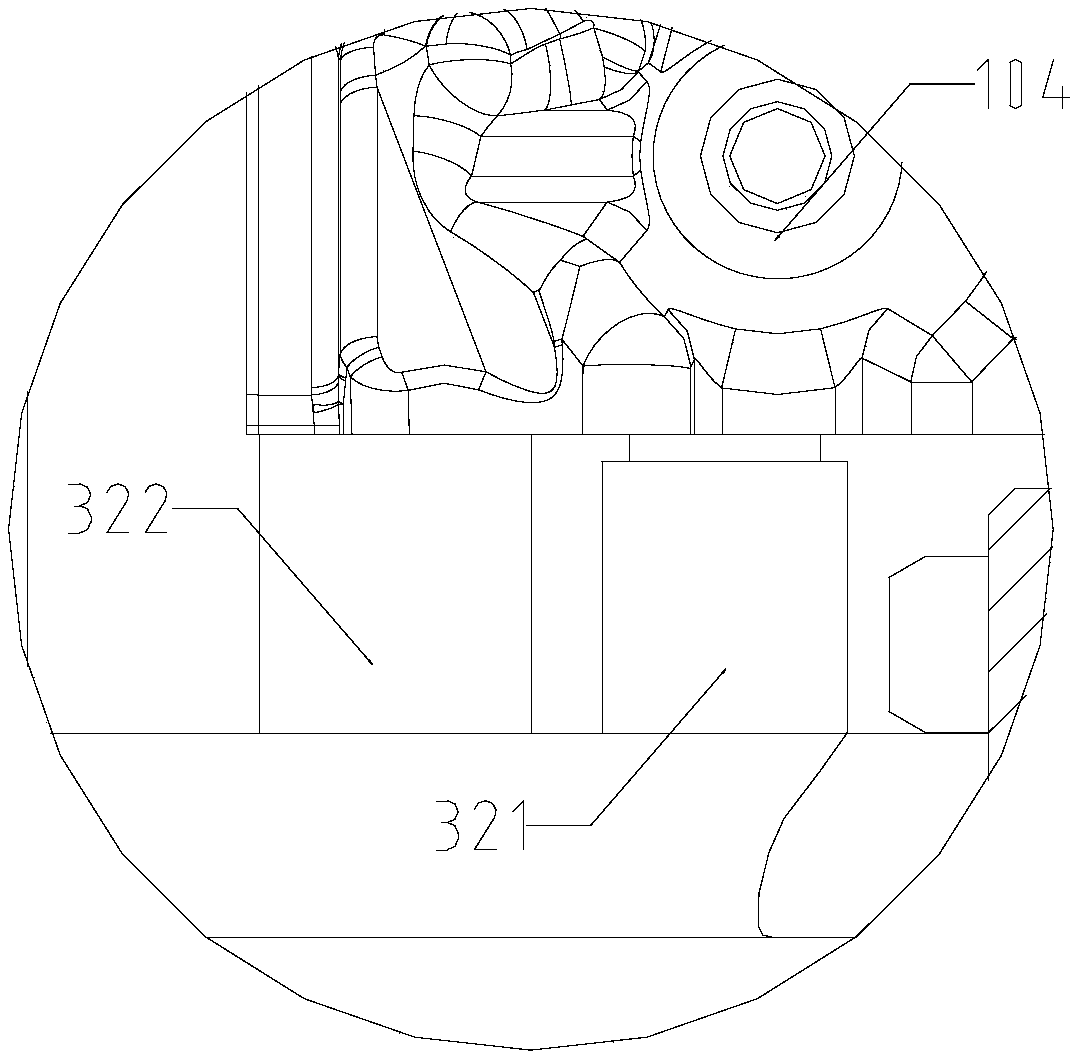

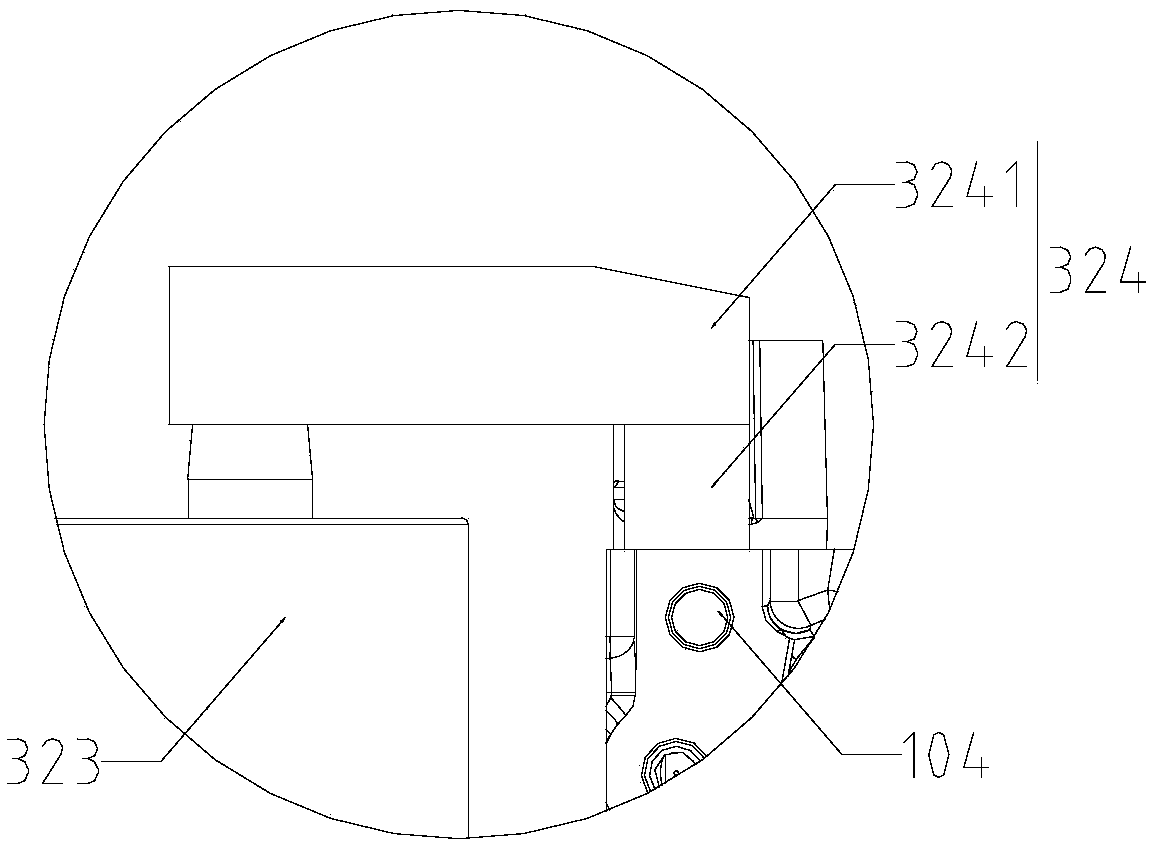

[0043] Such as Figure 1 to Figure 6 As shown, the internal iron chip and slag removal machine for complex parts includes a machine base, a gear motor 2, a workpiece 104 platform 3, a rotating platform 4, a vibration motor 5, and a shock absorber 6;

[0044] The two ends of the rotary platform 4 are installed on the machine base through bearings 77, and the reduction motor 2 is installed on one side of the rotary platform 4 and connected with the rotary platform 4; the workpiece 104 platform 3 is connected with the rotary platform 4 through the shock absorber 6; the vibration motor 5 installed on the working platform.

[0045] By placing the workpiece 104 on the workpiece 104 platform 3, and then by the vibration of the vibration motor 5, the iron filings inside the workpiece 104 can be separated from the workpiece 104, and then the reduction motor 2 can drive the workpiece 104 to rotate to separate the workpiece 104. The iron filings are discharged from the inside of the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com