Grouting equipment achieving station self-induction time-sharing drive and application method and PLC inner control circuit of grouting equipment

A time-sharing drive and self-sensing technology, which is applied in the field of grouting equipment and PLC internal control circuit, can solve the problems of waiting for a certain time, inaccurate judgment of slurry fullness, and low degree of automation, so as to improve production efficiency and control precision , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below through specific embodiments.

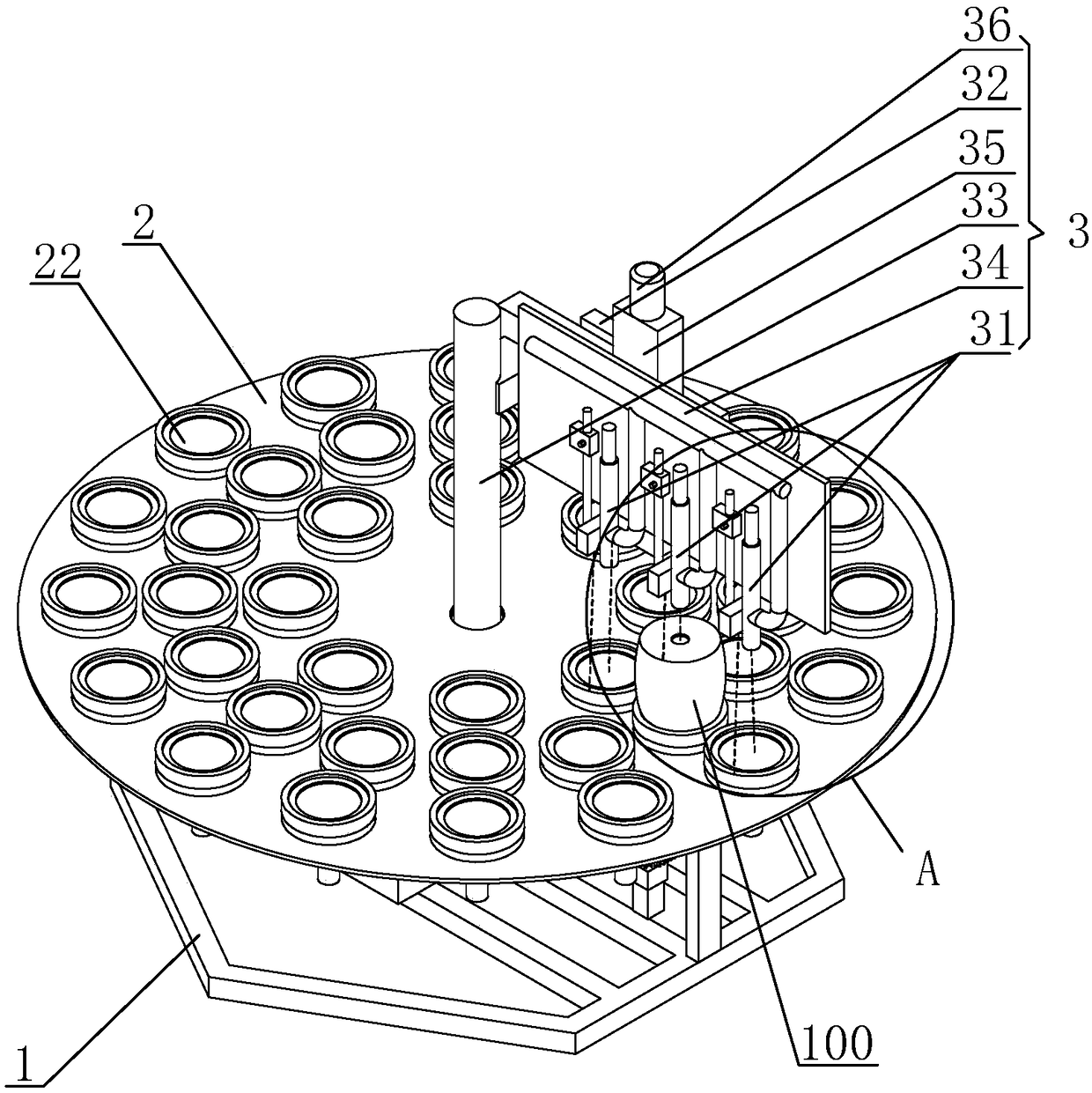

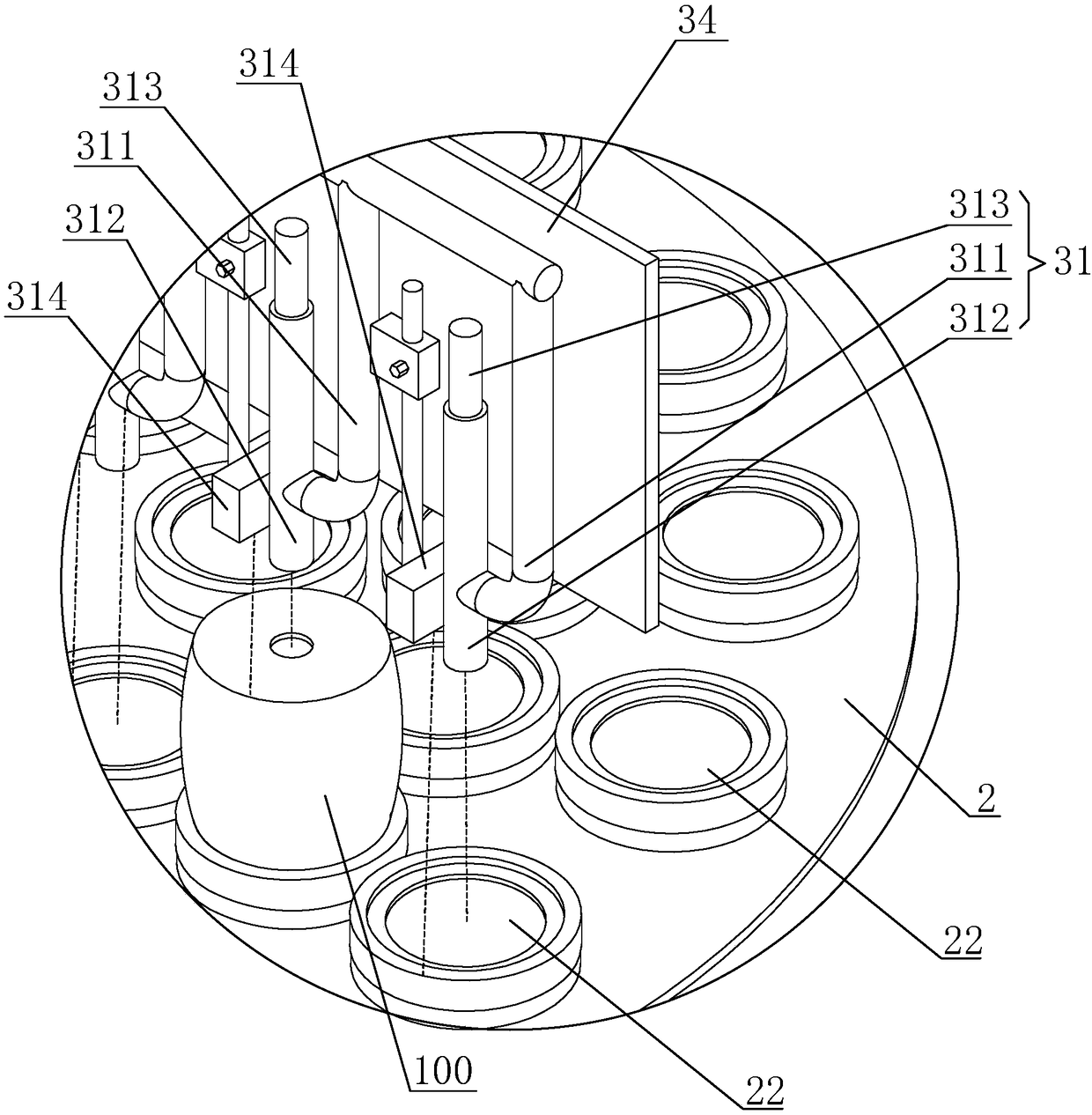

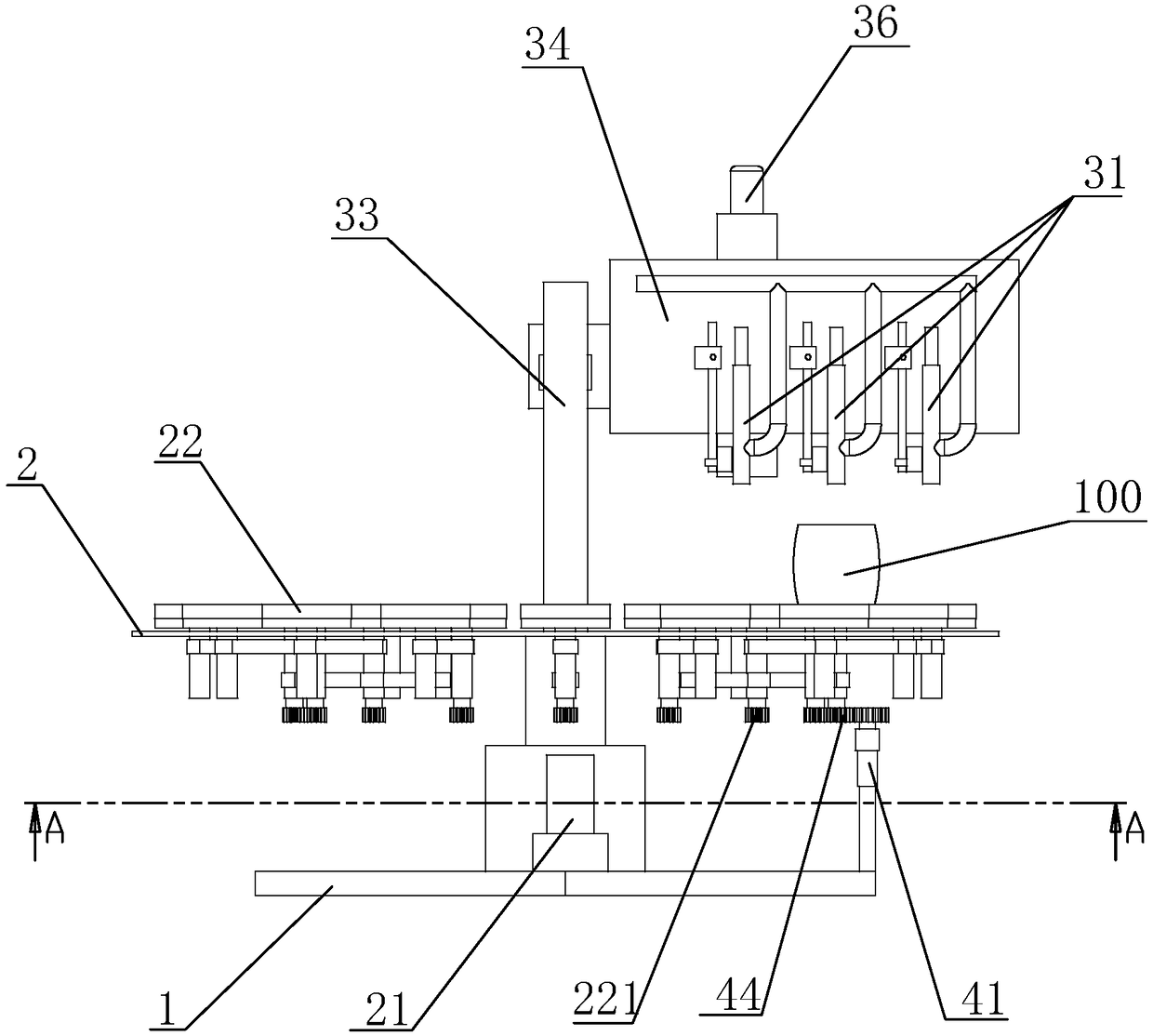

[0030] like Figures 1 to 6 As shown, the station self-induction time-sharing driven grouting equipment of the present invention includes a base 1, a turntable 2 rotatably arranged on the base 1, a grouting device 3 and a power split device 4, and the turntable 2 is driven by a turntable motor 21 Driven to rotate, the turntable motor 21 is connected to the turntable 2 through a reducer. There are multiple grouting disks 22 rotatably arranged on the turntable 2. The grouting device 3 is arranged above the turntable 2. The grouting disk 22 follows the turntable 2 and reaches the injector When the grouting device 3 is below, the grouting disc 22 is connected to the power split device 4, and the grouting disc 22 is connected to the power of the power splitting device 4 and rotates by itself.

[0031] The grouting discs 22 are distributed on the turntable 2 with the axis of rotation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com