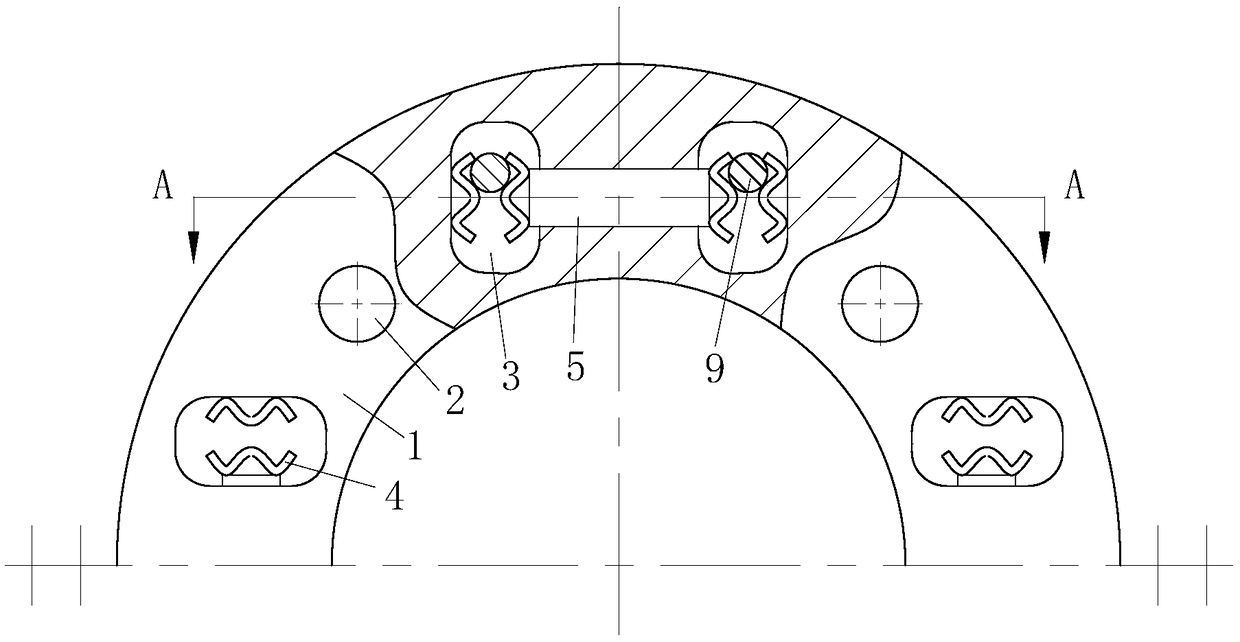

Bending moment resist flange plate for petroleum pipeline

A kind of oil pipeline, bending moment resistance technology, applied in flange connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problem of pipeline leakage, weak supporting force at the joint, easy bending or breaking of the joint of the pipeline, etc. problem, to achieve the effect of improving the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

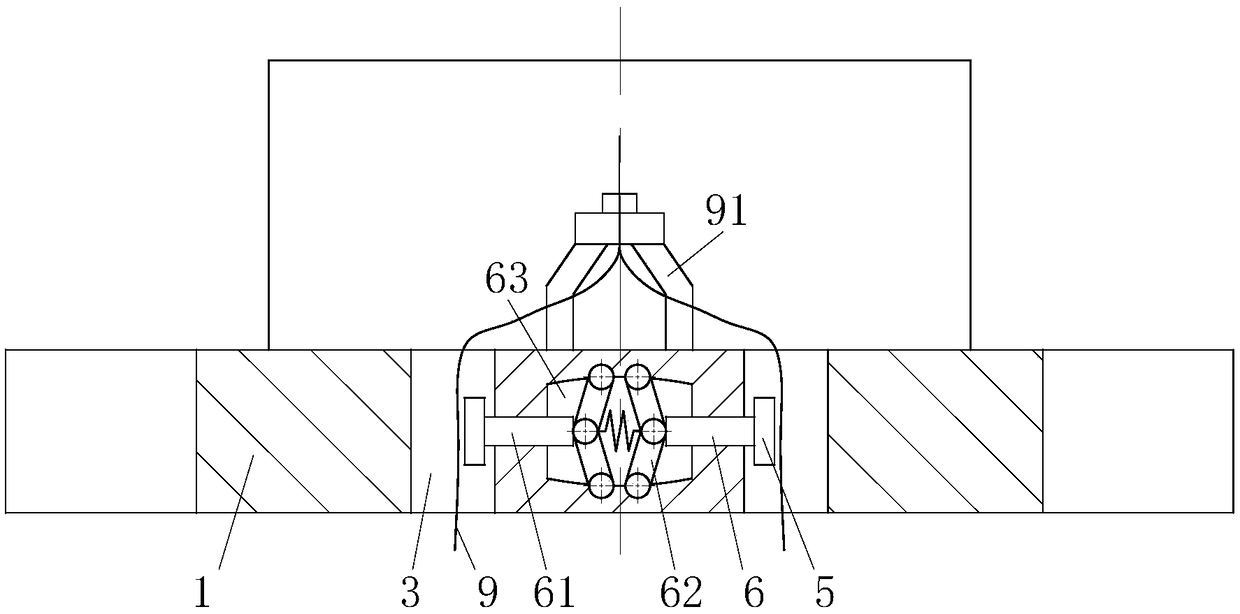

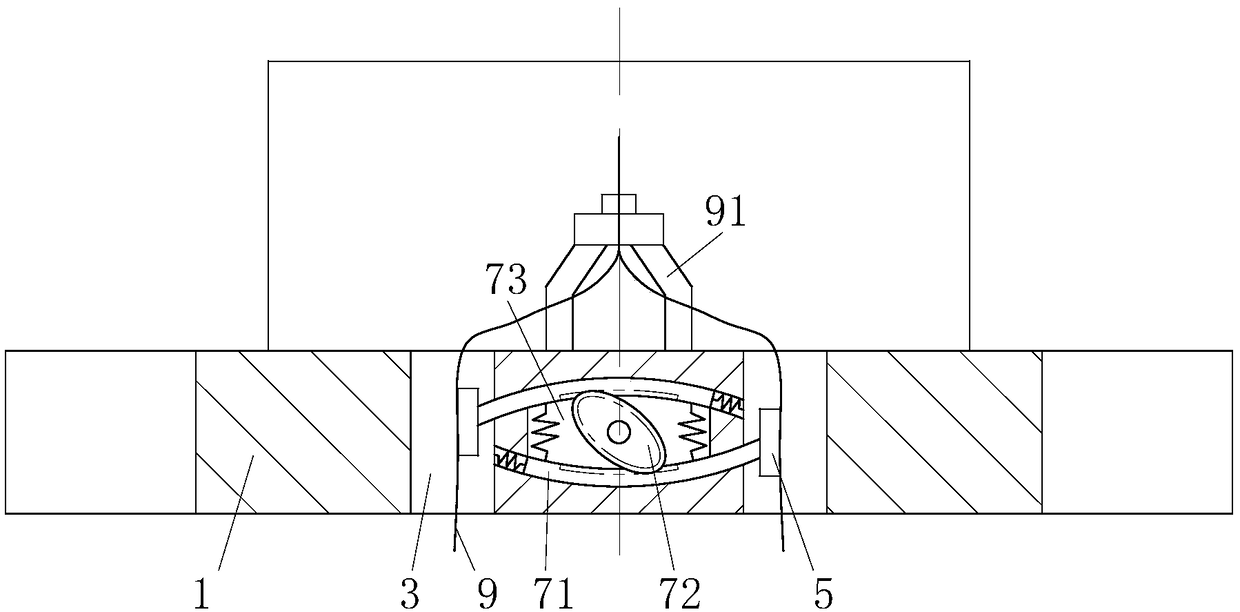

[0023] As an embodiment of the present invention, the middle part of the shrapnel 4 on the inner side of the waist-shaped hole 3 is a circular arc-shaped protrusion; the inner surface of the arc-shaped protrusion is connected by a connecting rod 41; the connecting rod 41 is provided with a vertical The adjusting rod 42 on the connecting rod 41; one end of the adjusting rod 42 is slidably installed in the base body 1; the other end of the adjusting rod 42 is fixedly connected to the middle part of the elastic piece 4; the adjusting rod between the connecting rod 41 and the elastic piece 4 Cylindrical protrusion 43 is set on 42 . During work, the arc protrusion of the shrapnel 4 can be retracted inwardly by pushing the adjusting rod 42. After the arc protrusion of the shrapnel 4 is retracted, it is convenient to move the position of the steel strand 9, and by changing the position of the anchor, thereby Realize different anchor strengths.

[0024] As an embodiment of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com