Positioning adjusting frame and laser detection device with same

A technology of positioning adjustment and laser detector, applied in the direction of measuring device, using optical device to transmit sensing components, measuring instrument components, etc. Stability, improve adjustment accuracy, increase the effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

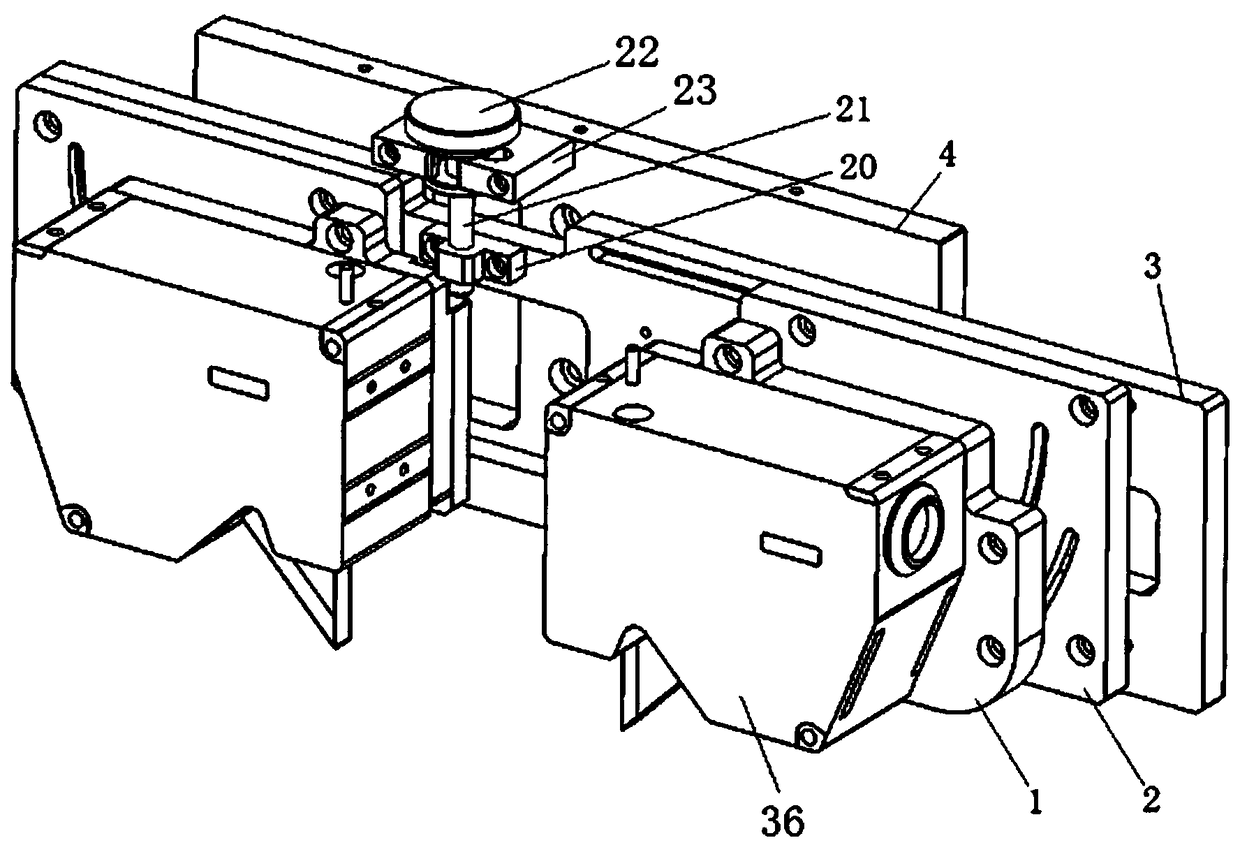

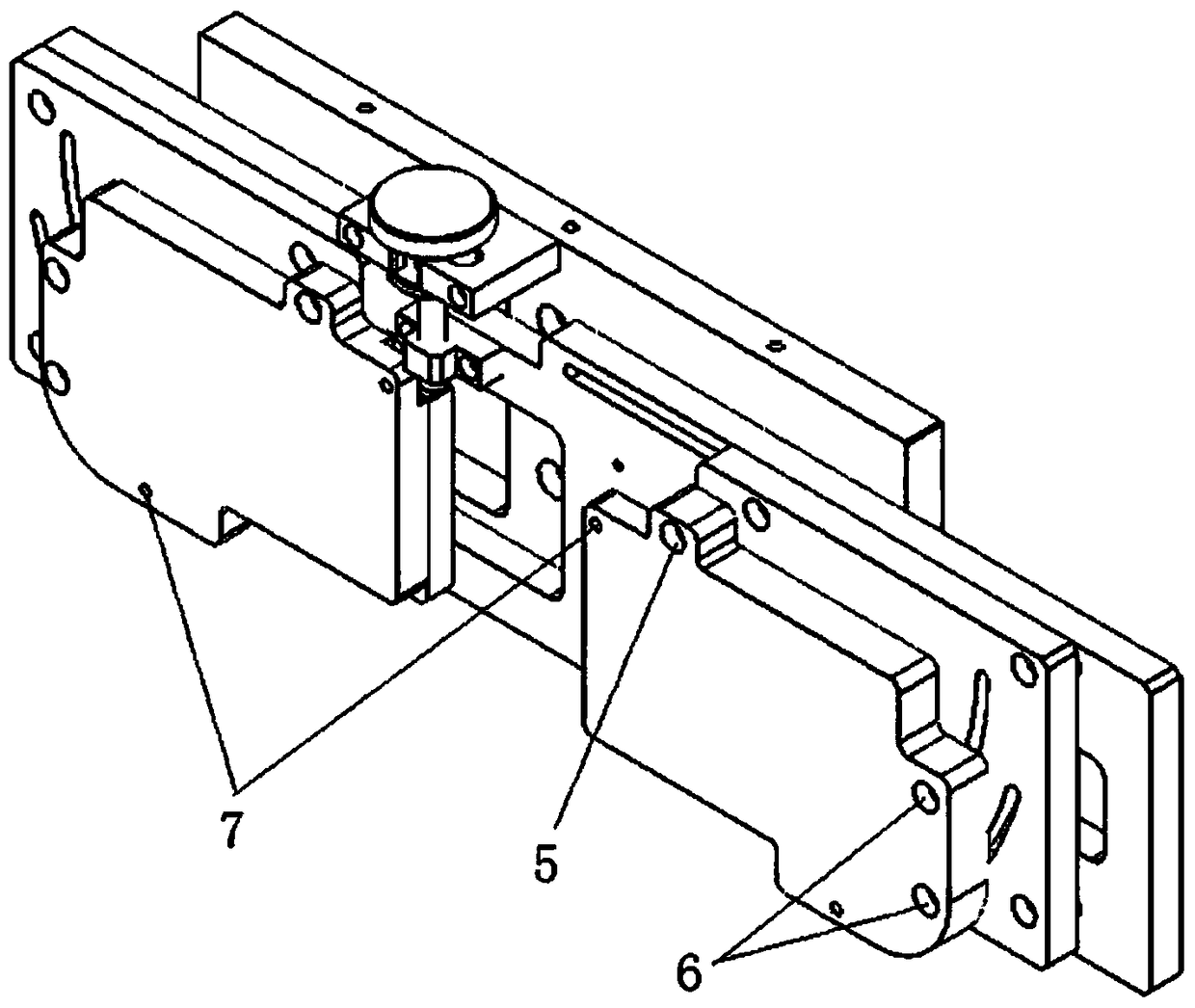

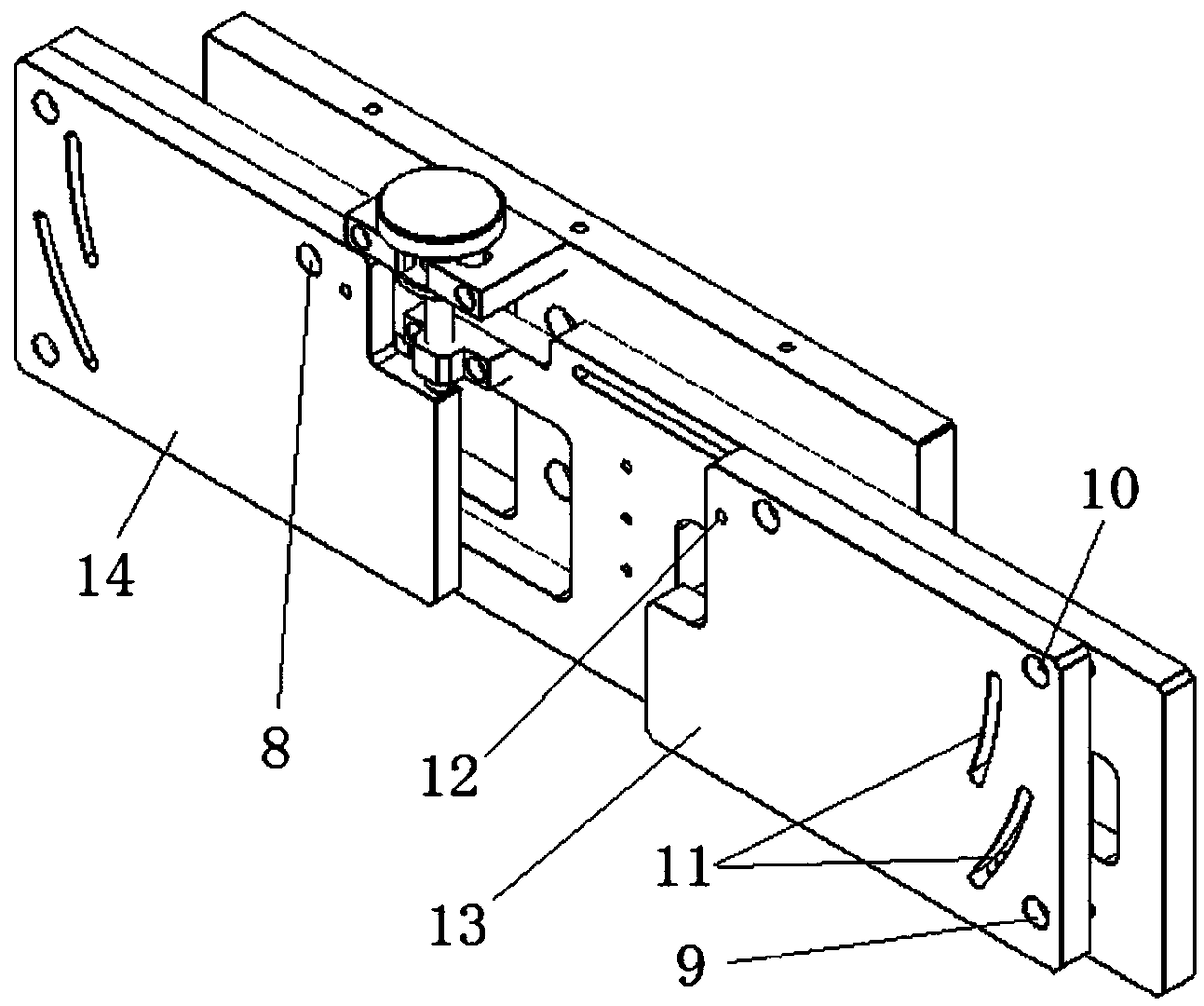

[0080] This embodiment provides a positioning adjustment frame, including an angle adjustment plate 1, a coordinate adjustment plate 2, a height adjustment plate 3, a bottom plate 4 and a height adjustment device.

[0081] There are three through holes for adjusting the angle on the angle adjustment plate 1, and the three through holes are not on the same straight line, one of which is a positioning hole 5, and the other two are angle adjustment holes 6, through which the bolts pass through to adjust the angle. The through hole on the board 1 is connected with the coordinate adjustment board 2, wherein the screw passing through the positioning hole 5 forms a hinge for the angle adjustment board 1 and the coordinate adjustment board 2 before being tightened, and the two screws passing through the angle adjustment hole 6 Before tightening, it can move in an arc with the positioning hole 5 as the center, so that the angle adjustment plate 1 can also slide around the positioning ho...

Embodiment 2

[0104] This embodiment provides a laser detection device, including a laser detector 27 , a positioning adjustment frame and a moving support, and the positioning adjustment frame is the positioning adjustment frame described in Embodiment 1.

[0105] The laser detector 27 is fixed on the angle adjustment plate 1 of the positioning adjustment frame, and the positioning adjustment frame is connected to the moving bracket.

[0106] The mobile support is a cantilever beam type mobile support, comprising: a mobile beam 28 and a fixed support 29 . The moving crossbeam 28 is connected to the fixed support 29 to form a cantilever structure through a linear slide and an electric slide, and the bottom plate 4 of the positioning adjustment frame is connected to the movable crossbeam 28 through another set of linear slides and electric slides. bottom.

[0107] The linear slide table includes a linear guide rail 30 and an aluminum alloy profile 31 . The linear guide rail 30 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com