Speed sensor testing device and measurement method

Technology of a speed sensor and testing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be described in further detail below in conjunction with the embodiments of the accompanying drawings.

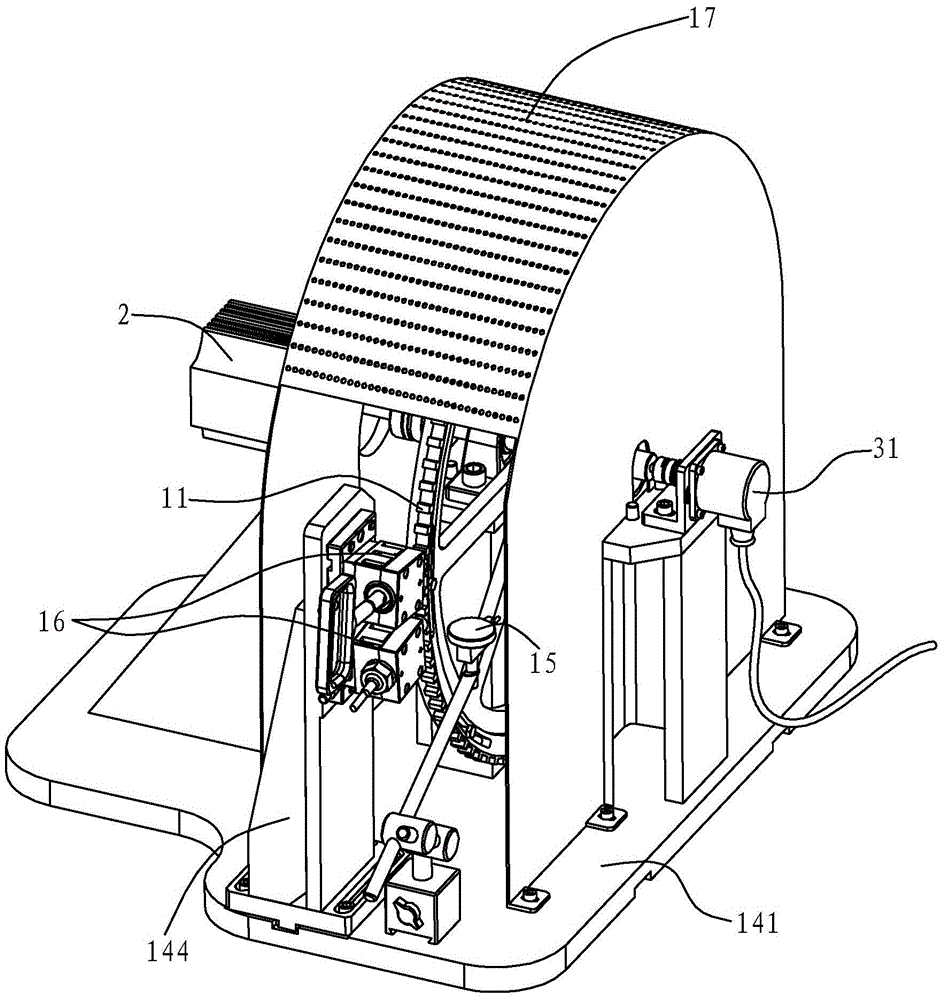

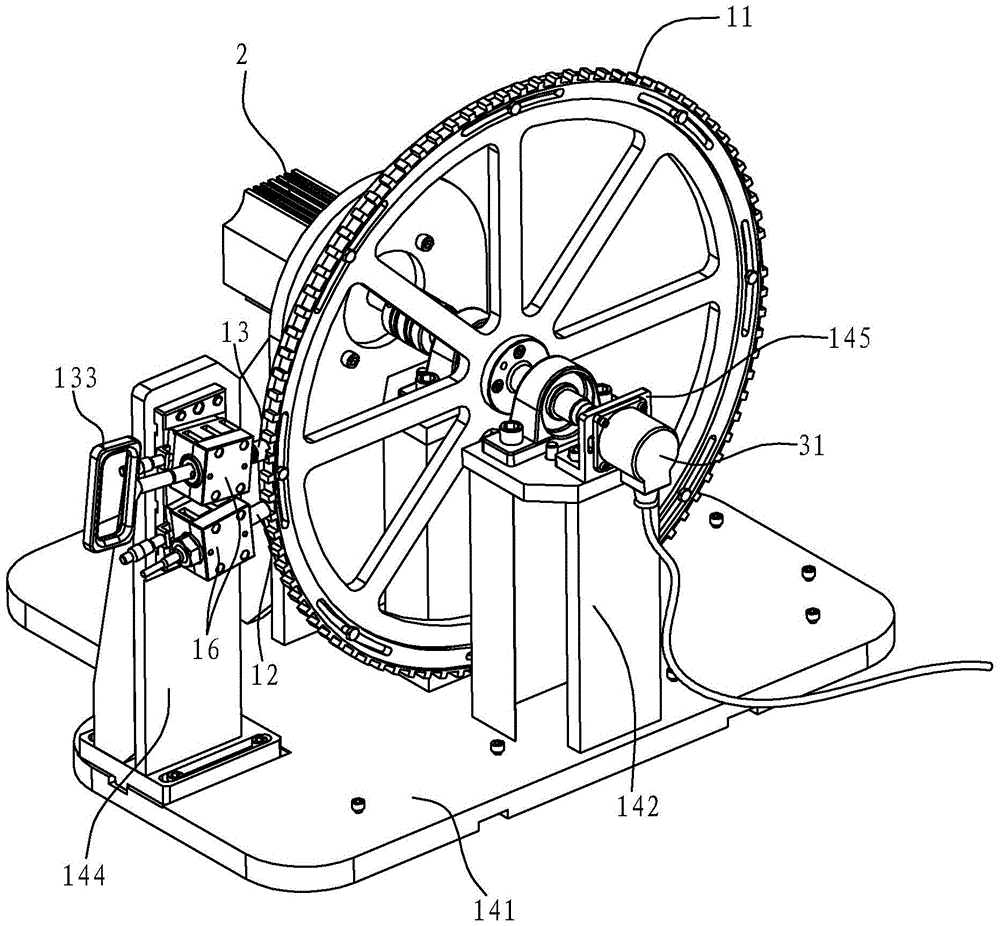

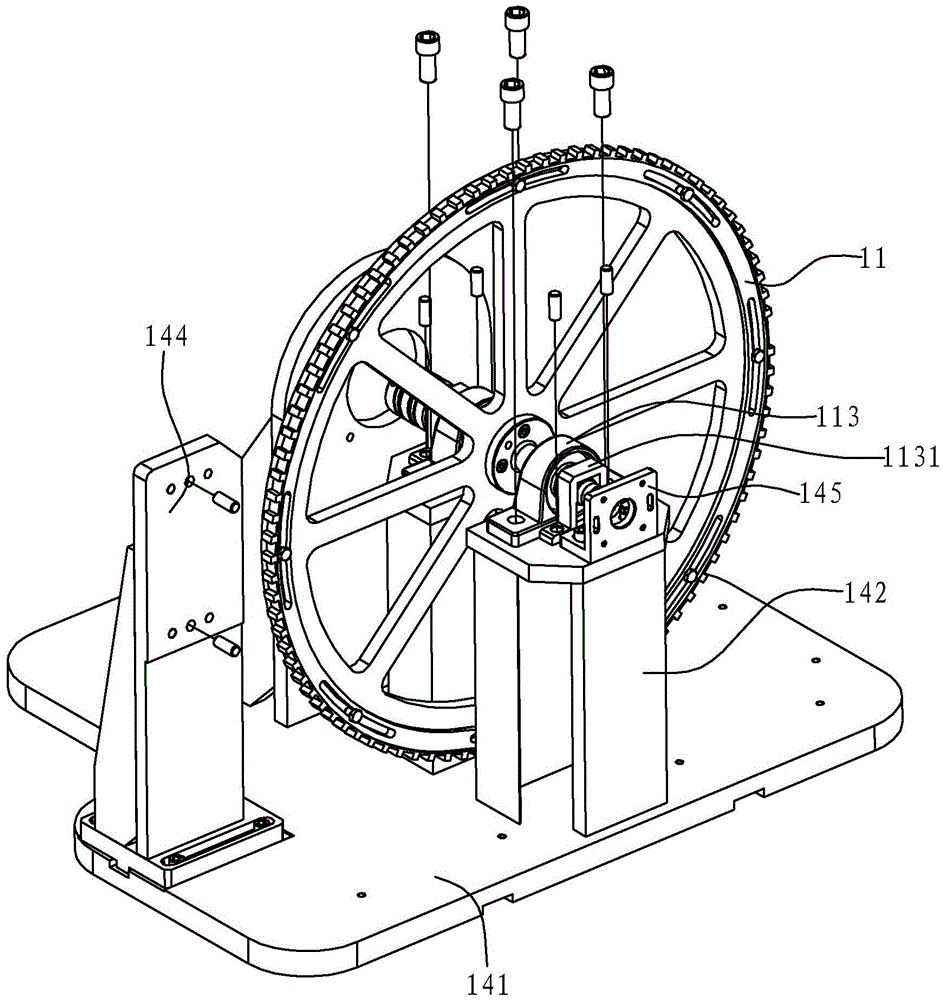

[0068] Such as Figure 1 to Figure 11 As shown, the speed sensor test device in this embodiment includes a test mechanism 1 for providing a structural basis for the speed sensor test, and a power mechanism 2 for providing power for the test mechanism 1, for realizing the output signal of the speed sensor 12 and Electrical system for gear rotation signal measurement 3.

[0069] Wherein the power mechanism 2 can adopt a mechanism that can provide power for the test mechanism 1 such as a motor and its matching motor control system. The ionization mechanism in this embodiment includes a DC brushed permanent magnet motor and its corresponding motor control system. The DC motor can choose the CDP3445 model of BALDOR. The power of the motor is 1.5kw, and the maximum speed is 1750r / min. The motor control system can display the current motor spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com