Shell plating automatic expansion method based on AutoCAD

An automatic unfolding and plate unfolding technology, which is applied in geometric CAD, special data processing applications, instruments, etc., can solve the problems of long consumption cycle, cumbersome process, and shortage, achieve a high degree of automation, and improve the effect of drawing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

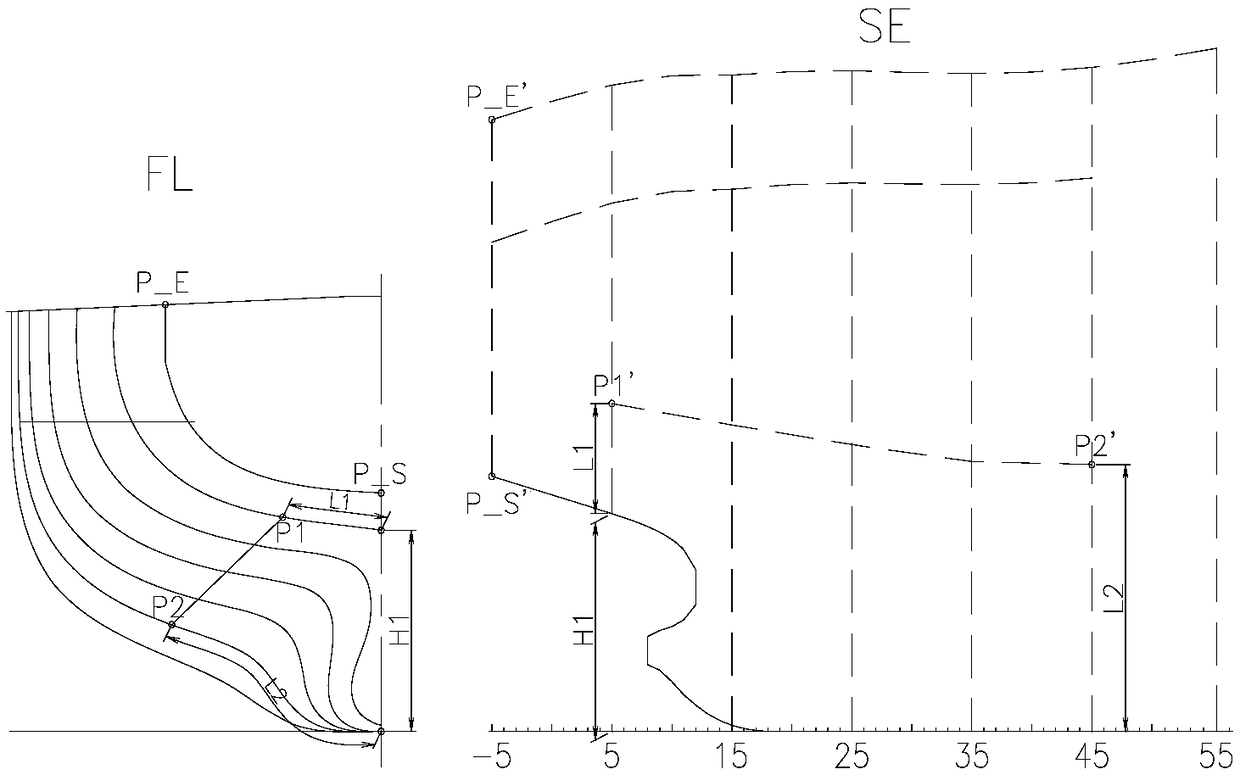

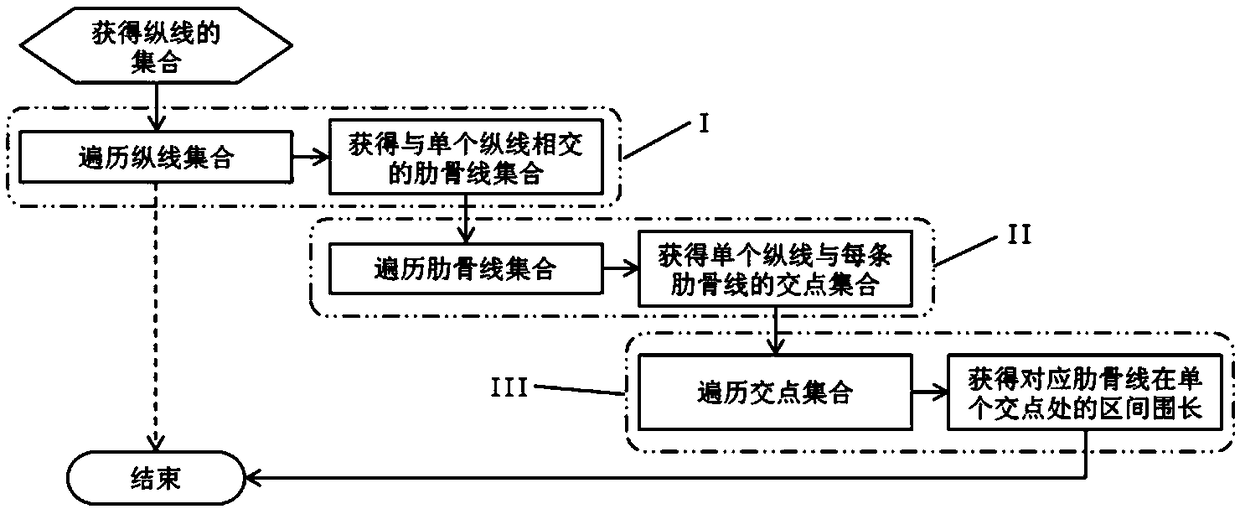

[0041] The AutoCAD-based automatic unfolding method of the outer panel of the present invention, by unfolding FL into SE, the key is to obtain the intersection point of the longitudinal line on the FL and the rib line, and calculate the coordinates of the corresponding point on the SE. Here, two concepts are defined first: 1) Rib line: generally refers to any member line, plate suture line or other virtual line on the surface of the hull plate within the plane of the rib. 2) Longitudinal line: generally refers to any member line, plate seam line or other virtual line intersecting with the frame line on the hull surface. The hull molding is made up of both.

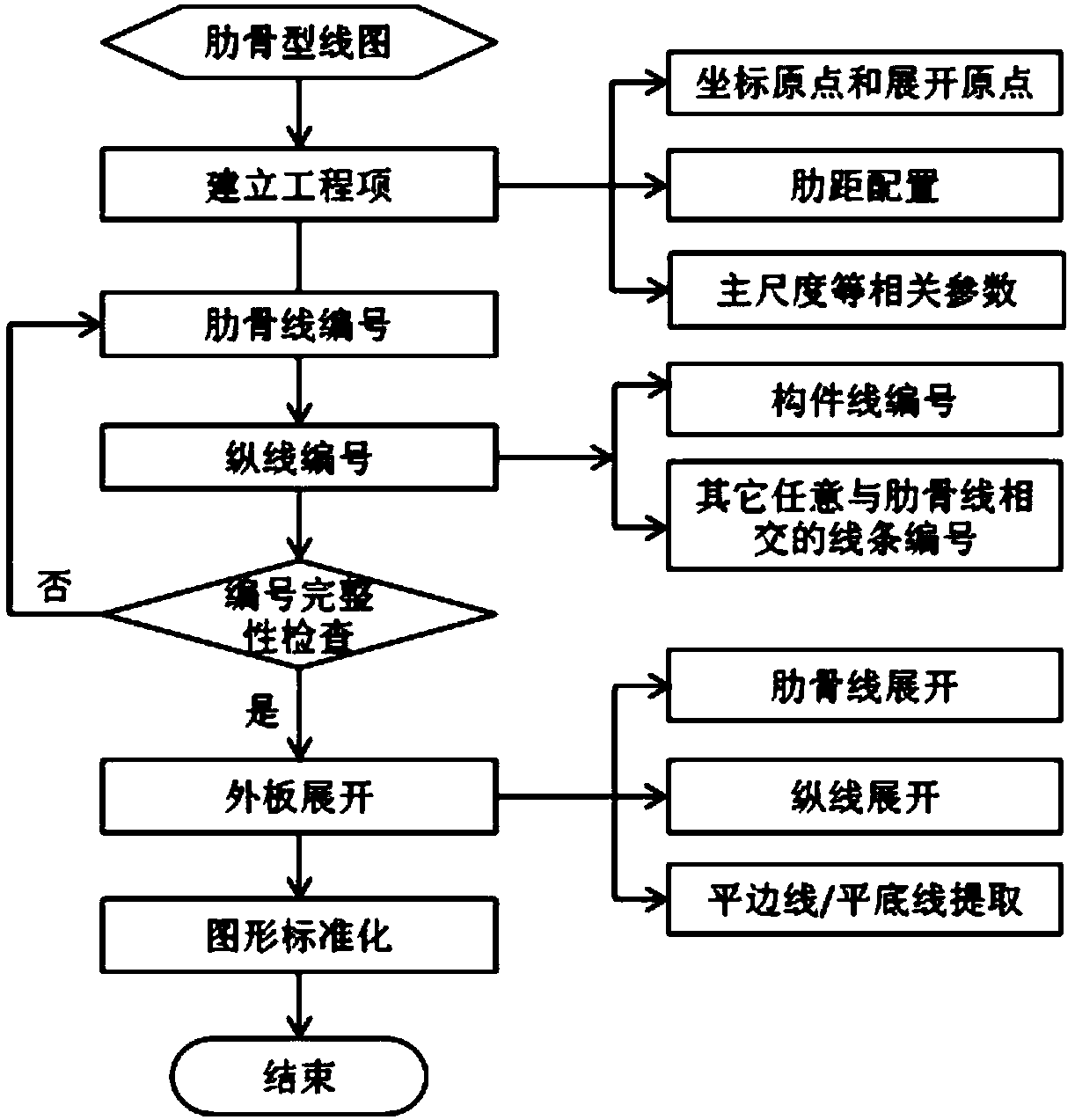

[0042] see figure 1 , the method for automatic expansion of the outer panel includes the following steps:

[0043] 1. Establish project items: Write all fixed input conditions required in the process of unfolding th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com