Method and system for quickly drawing complex scene based on process factory parameter model

A parametric model and complex scene technology, applied in 3D modeling, image data processing, instruments, etc., can solve problems such as increased computing overhead, need for preprocessing time, complex process factory models, etc., to achieve fast construction speed and facilitate object search Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

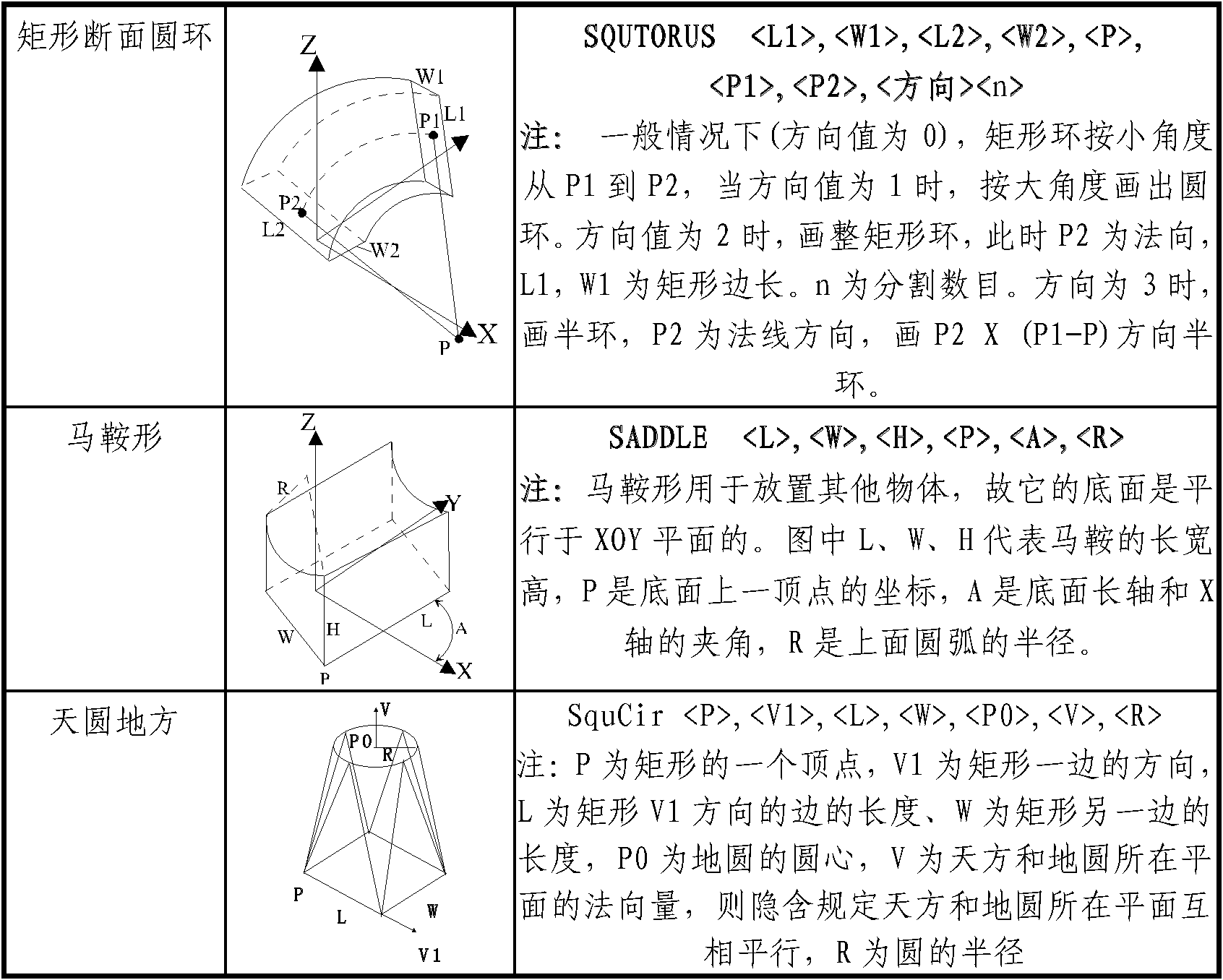

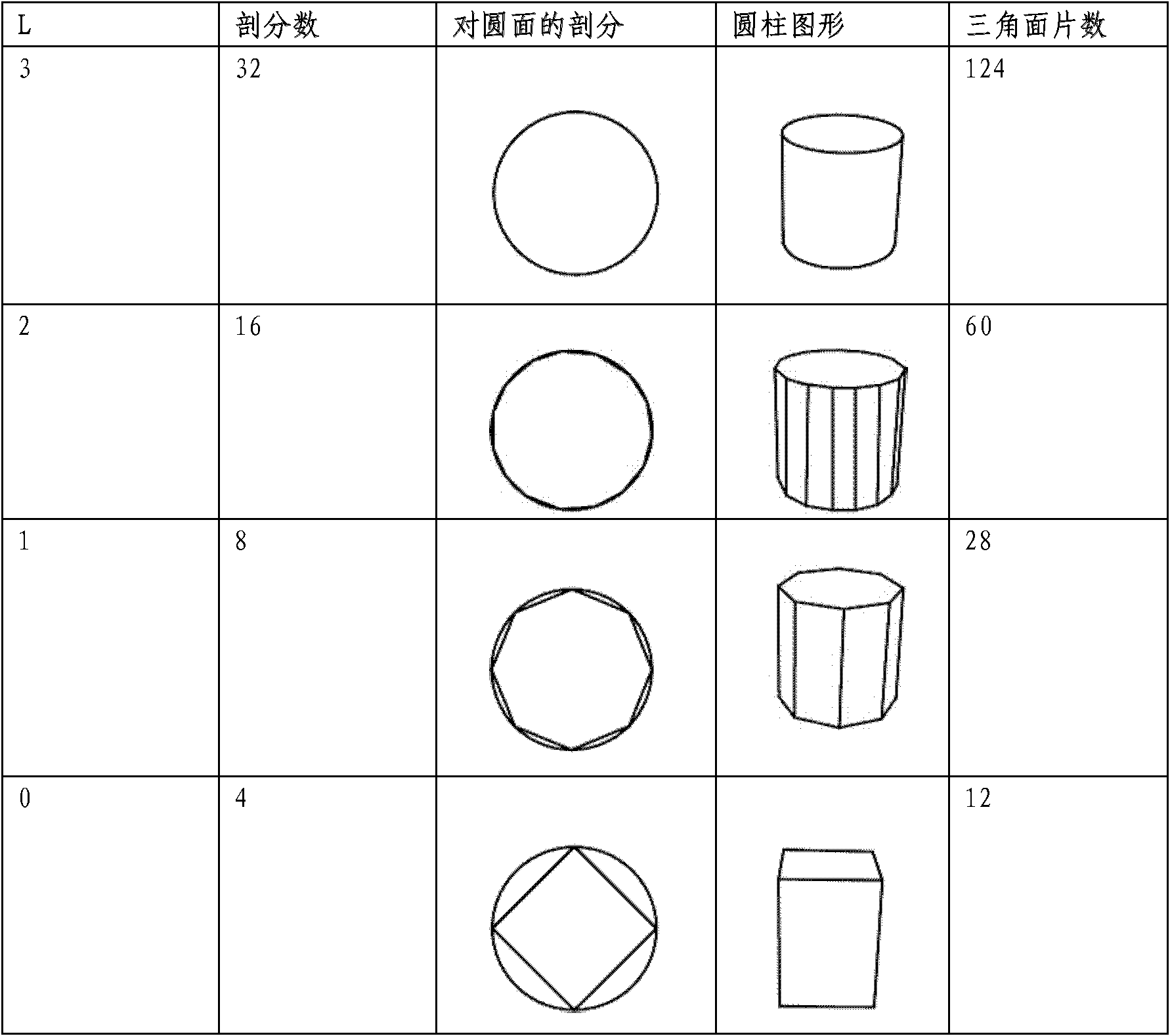

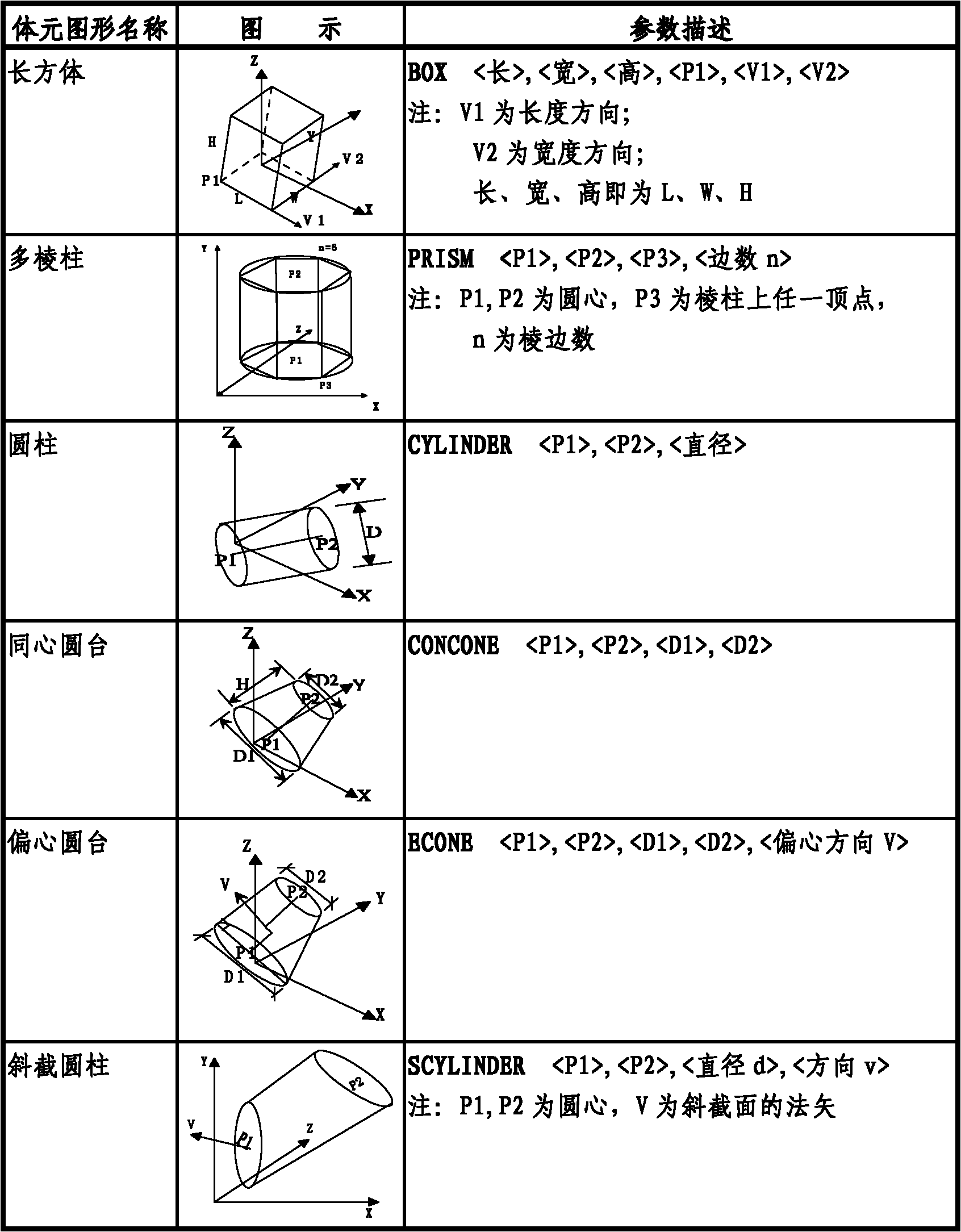

[0058] The complex scene rapid rendering method based on the process factory parameter model proposed by the present invention utilizes MFC and OpenGL to realize functions such as preprocessing and rendering of the process factory parameter model. It is described as follows in conjunction with accompanying drawings and examples.

[0059] The present invention proposes a complex scene rapid drawing method based on the process factory model, the process of which is as follows figure 1 As shown, it includes the preprocessing steps: parsing the parameter model of the process factory, constructing the scene tree, preprocessing the multi-resolution model of the voxel, and pre-filling the vertex buffer in the video memory; the rendering step: using viewshed culling, dynamic level of detail selection and Back-to-face culling technology is used for graphics drawing. Specifically, the preprocessing steps include the following steps:

[0060] S1. Analyzing the parametric model of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com