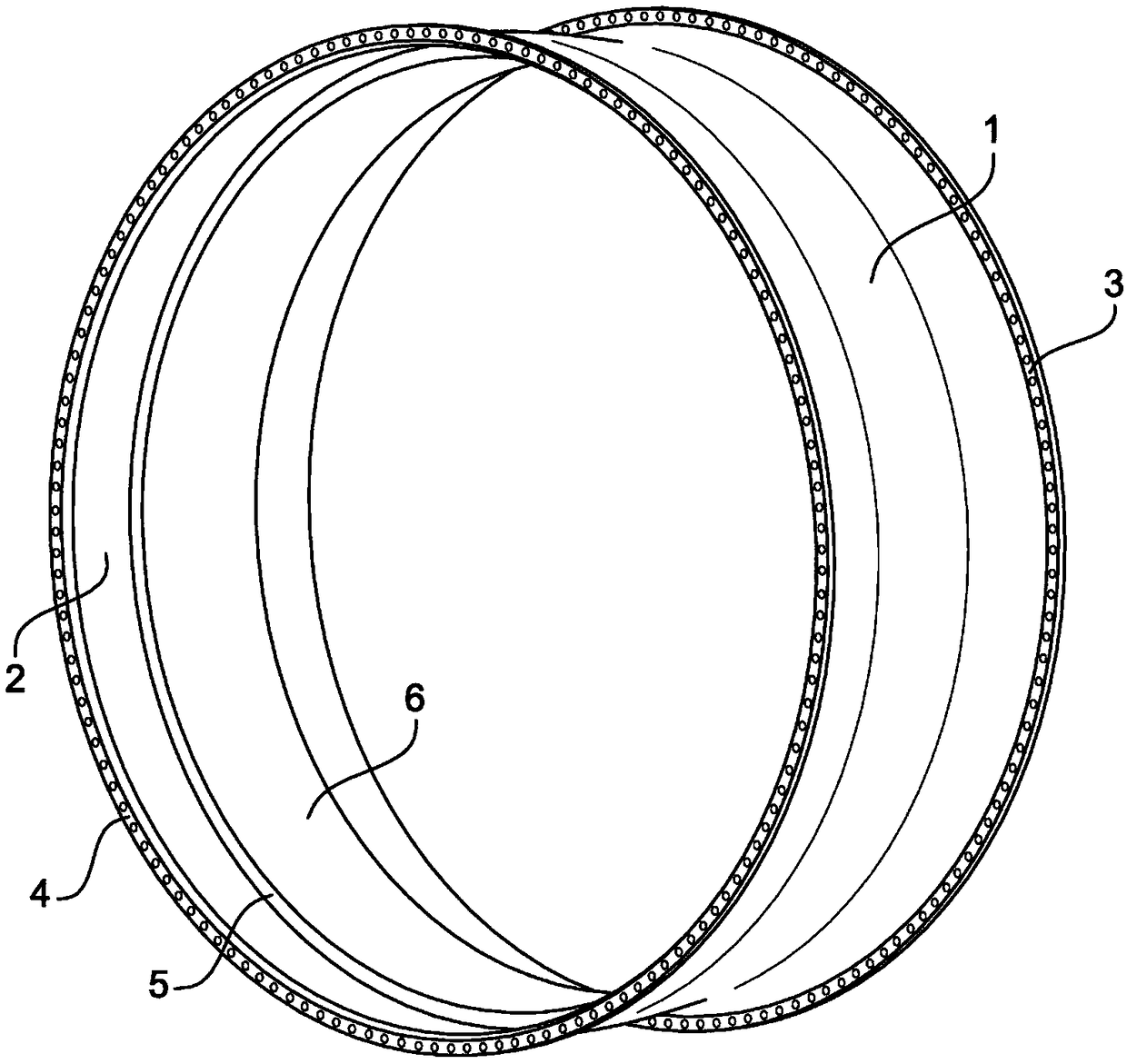

Device for applying abradable material to a surface of a turbomachine casing

A technology of turbine engine and wear-resistant material, which can be used in devices for coating liquid on surfaces, liquid fuel engines, engine components, etc., and can solve the problems of laborious and expensive, long manufacturing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

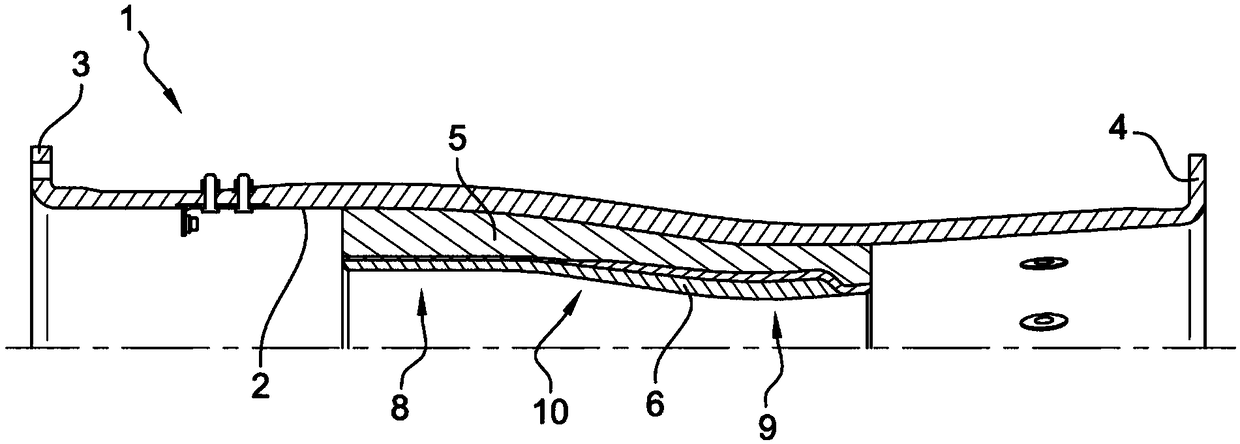

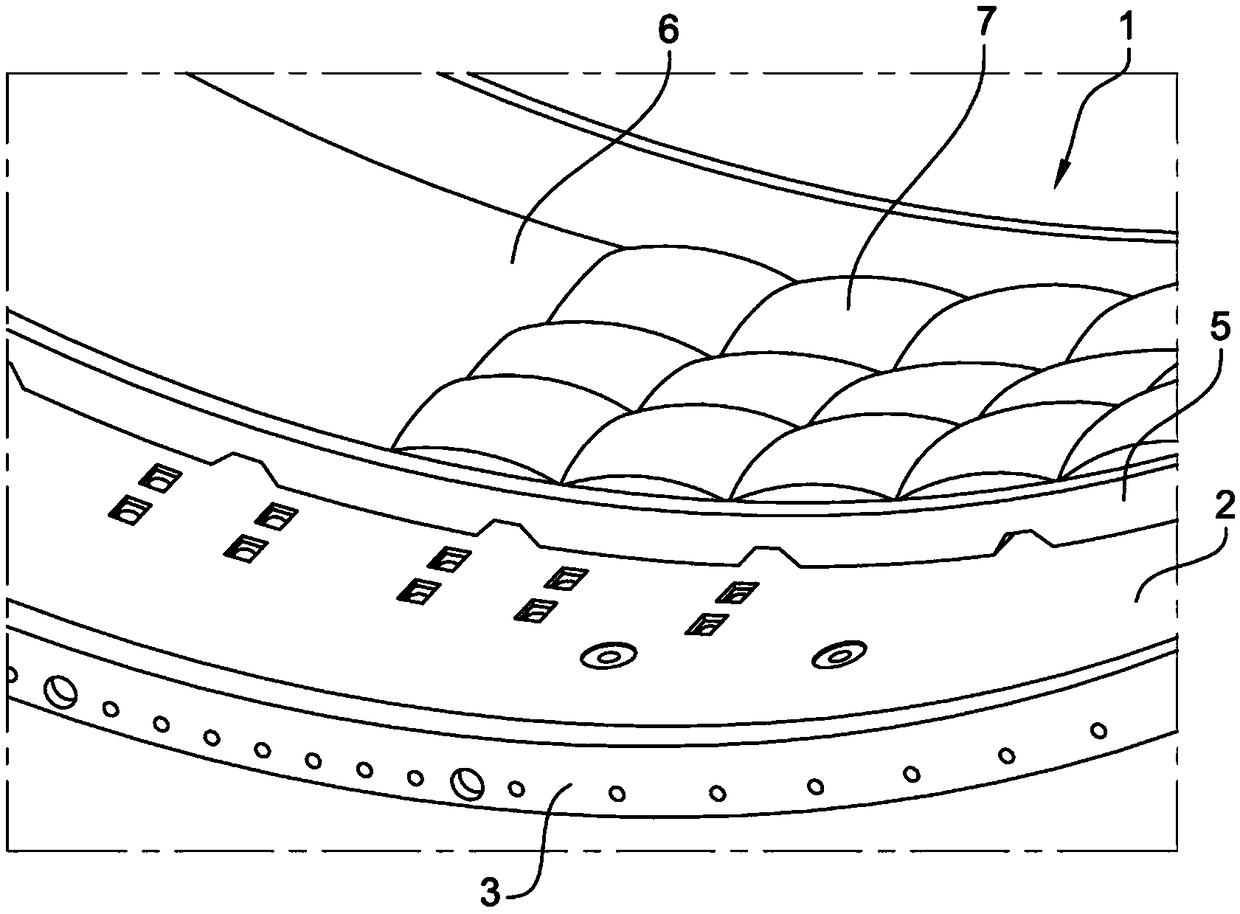

[0044] Figure 4 and Figure 5 A device 11 for applying abradable material is shown for applying abradable material to the surface of the turbine engine housing 1 .

[0045]The device 11 has a support comprising a first part 12 and a second part 13 . When viewed from the front, the first part 12 has an overall U-shape comprising a base 12a from which two branches 12b extend. The free end of each branch 12b has two opposite legs 12c each carrying a guide roller 14 whose axis of rotation 15 is parallel to the base 12a. The first part 12 of the support also comprises an additional branch 12d extending from the lateral end of the base 12a and parallel to the branch 12b. The free end of the additional branch 12d has two opposite legs 12e each carrying a guide roller 16 whose axis of rotation 17 is parallel to the branches 12b , 12d , ie perpendicular to the axis of rotation 15 of the guide roller 14 .

[0046] Two grab handles 18 are fixed to the base 12a, and a handle 19 is fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap