Manufacture method of covering yarn and covered edge quilt

A production method and hemming technology, which is applied in the direction of non-woven fabrics, textiles, papermaking, bed sheets, etc., can solve the problems of cotton shifting and linters running out, so as to improve the shifting, increase the strength, and improve the tendency to shift. bit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

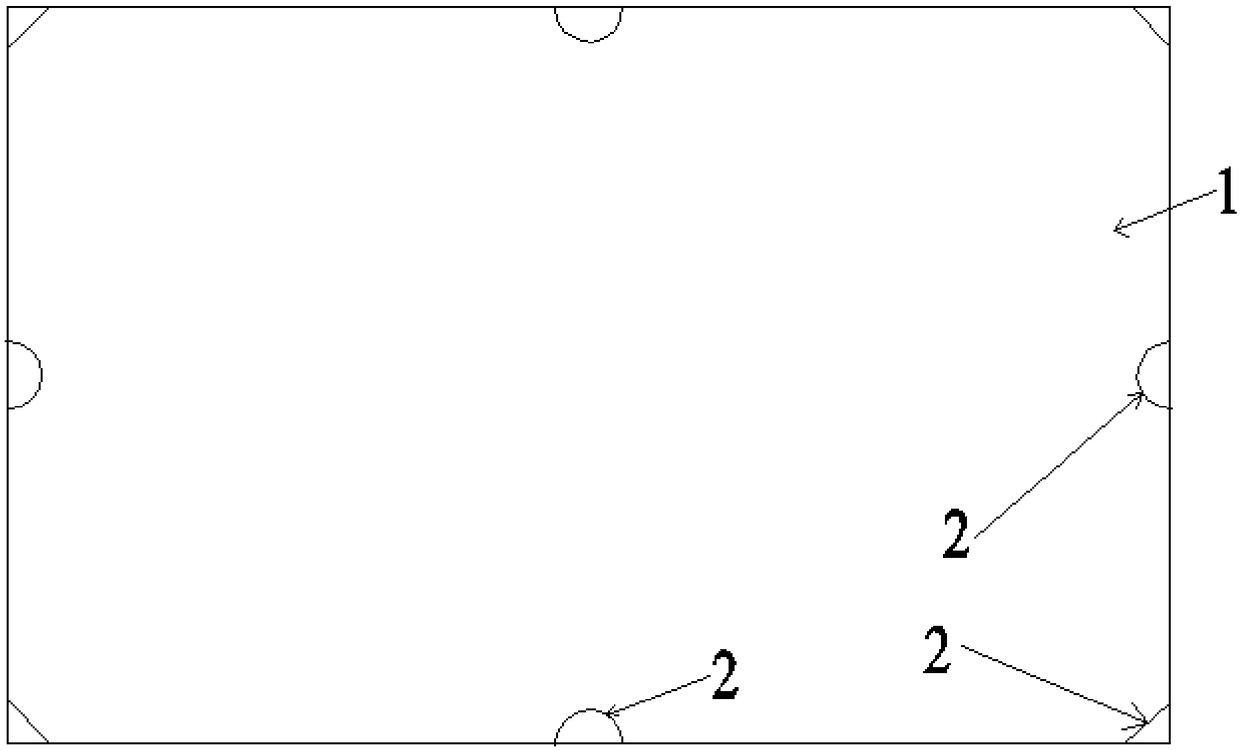

Image

Examples

Embodiment 1

[0055] The preparation method of the yarn-wrapped quilt provided by the invention comprises the following steps:

[0056] S1 feeds the cotton into the combined opening and cleaning machine and processes it into laps;

[0057] S2 feeds the cotton lap into the carding machine and processes it into a fiber web layer;

[0058] S3 uses the fiber net layer to lay the net to make a fluffy first cotton layer structure in a stacked state;

[0059] S4 disconnecting the first cotton layer structure according to the specified size to make a plurality of second cotton layer structures;

[0060] S5 winds yarn on the surface of each second cotton layer structure to make a third cotton layer structure;

[0061] S6 cuts off the yarn between two adjacent third cotton layer structures, and turns the disconnected yarn onto the third cotton layer structure;

[0062] S7 kneads and grinds the third cotton layer structure processed in step S6 to make a cotton tire;

[0063] S8 Put a gauze cover o...

Embodiment 2

[0088] The manufacturing method of the yarn-wrapped quilt provided in this embodiment comprises the following steps:

[0089] S1 feeds the cotton into the combined opening and cleaning machine and processes it into laps;

[0090] S2 feeds the cotton lap into the carding machine and processes it into a fiber web layer;

[0091] S3 uses the fiber net layer to lay the net to make a fluffy first cotton layer structure in a stacked state;

[0092] S4 disconnecting the first cotton layer structure according to the specified size to make a plurality of second cotton layer structures;

[0093] S5 kneads and grinds the structure of the second cotton layer, and at the same time tears and wraps the edges to make a cotton tire;

[0094] S6 sets a gauze cover on the cotton base to make the third quilt core of the yarn-wrapped quilt;

[0095] S7 wraps cloth strips at each side of the third quilt core, and the cloth strips are sewn on the third quilt core to make the fourth quilt core of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com