Disposable environment-friendly heat preservation cover of molten iron conveying tank and use method

A technology of thermal insulation cover and conveying tank, which is applied in the direction of casting molten material container, metal processing equipment, casting equipment, etc., can solve the problems of difficult transformation of old enterprises, huge one-time investment, and difficulty in stable implementation, so as to improve the quality of molten iron, The effect of avoiding dust pollution and increasing mechanical strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

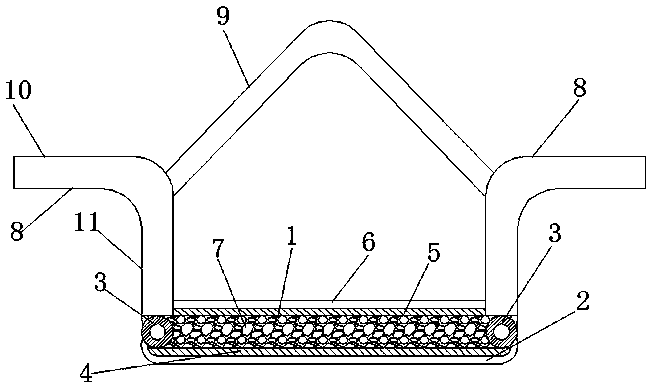

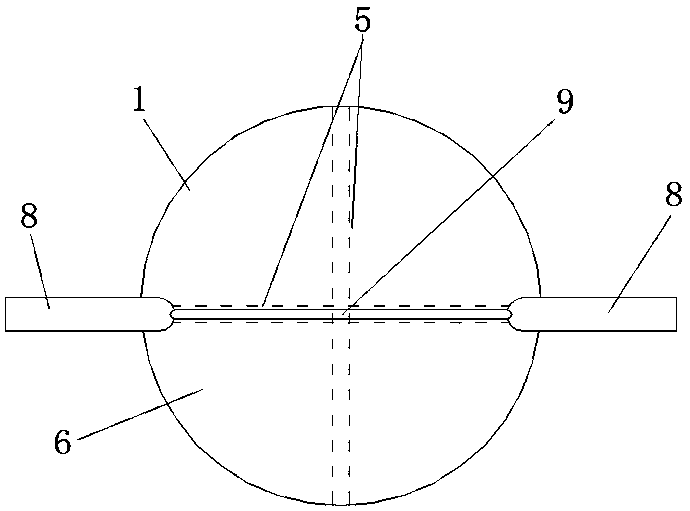

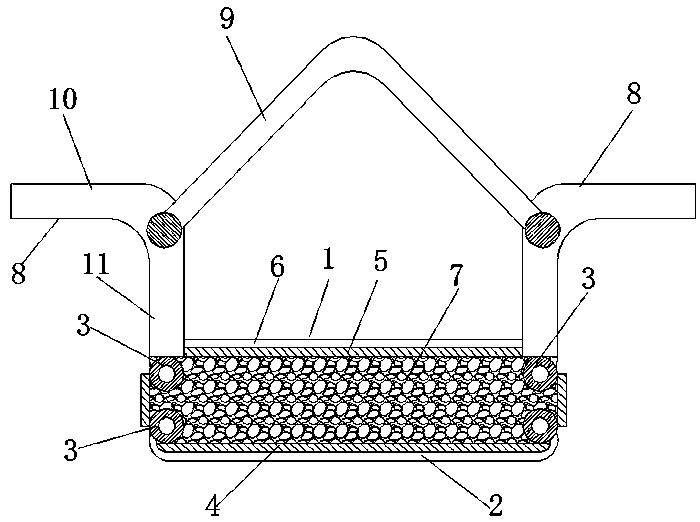

[0033] Below in conjunction with accompanying drawing the pre-structure of the present invention will be described in detail:

[0034] An environmentally friendly thermal insulation cover for a disposable molten iron delivery tank, comprising a cover body 1, wherein the cover body 1 is composed of a bottom plate 2, a support ring 3 connected to the bottom plate 2 by welding, and a support frame connected to the lower part of the support ring 3 by spot welding 1. 4. The support frame 2 that is connected with the support ring 3 by spot welding. The side welding is connected with a hook 8, and the hook 8 is connected with a hook frame 9.

[0035] The hook 8 is composed of a positioning cross bar 10 and a cover body insertion rod 11 through integral processing or welding; the cover body insertion rod 11 is adjustable.

[0036] The above-mentioned components constituting the environmental-friendly thermal insulation cover, except for the carbon thermal insulation layer 7, are all ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap