Internal expansion type tool for lathe turning

A turning and lathe technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve problems such as shaking, material damage, material reinforcement, etc., to increase stability, prevent processing damage, and save materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

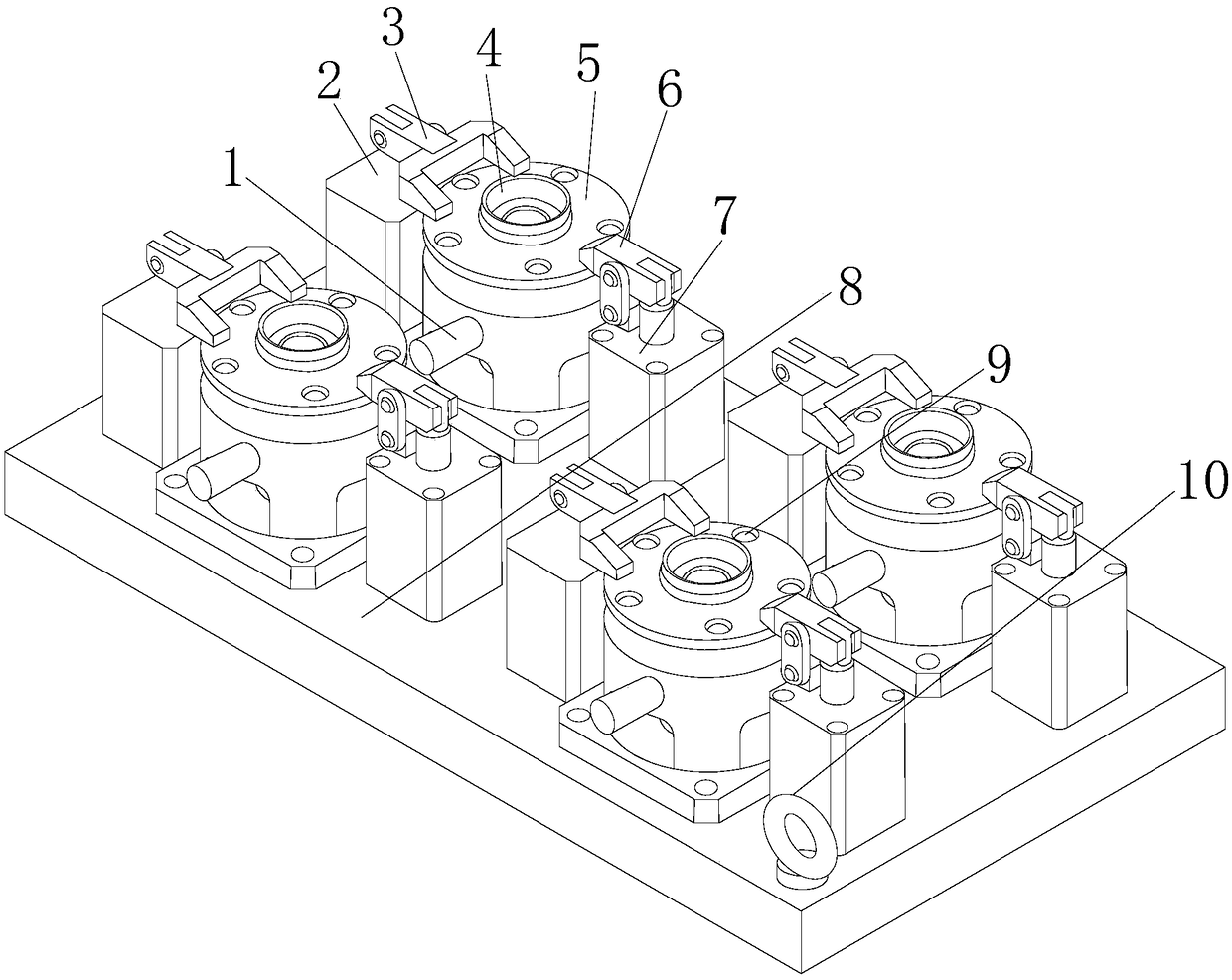

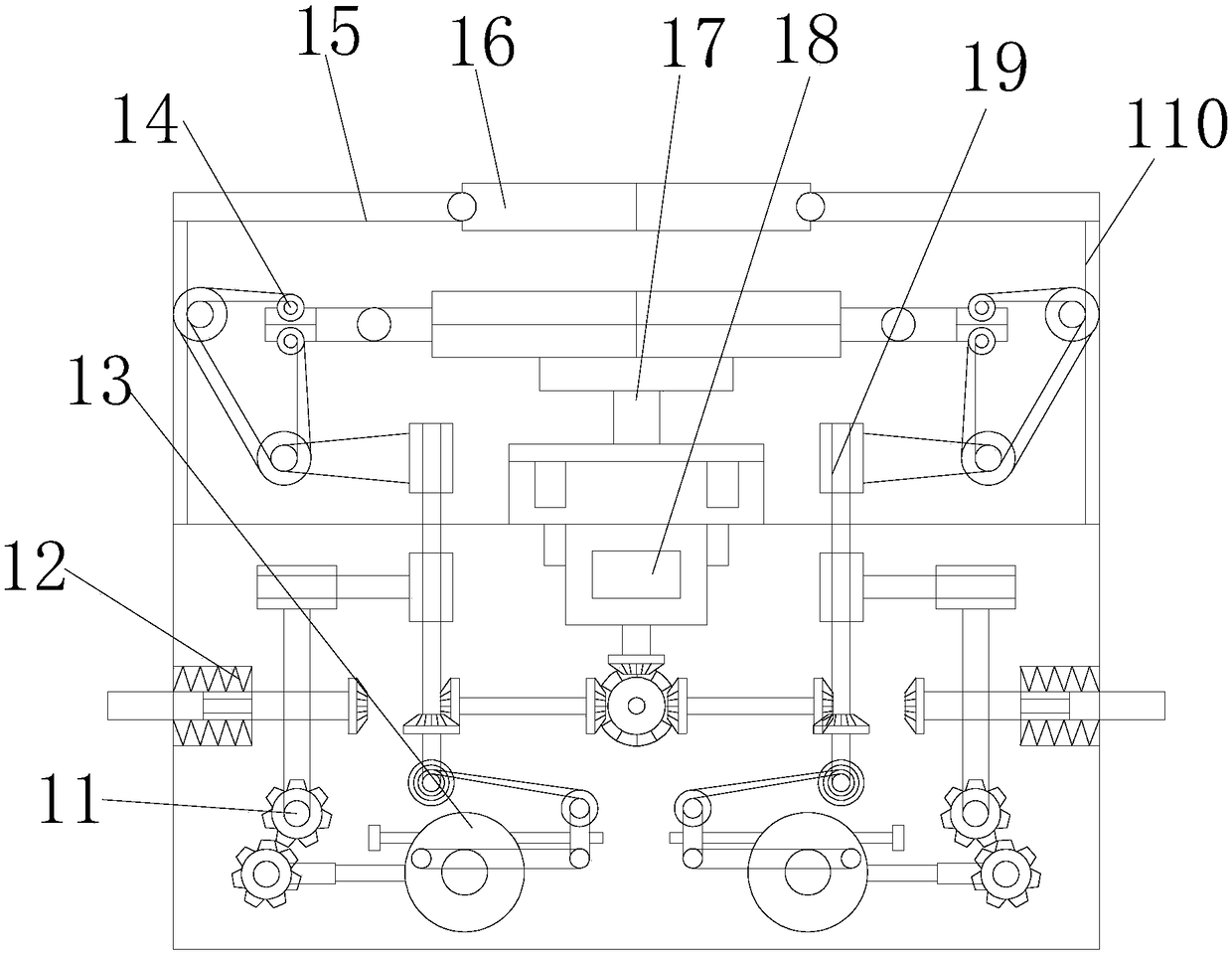

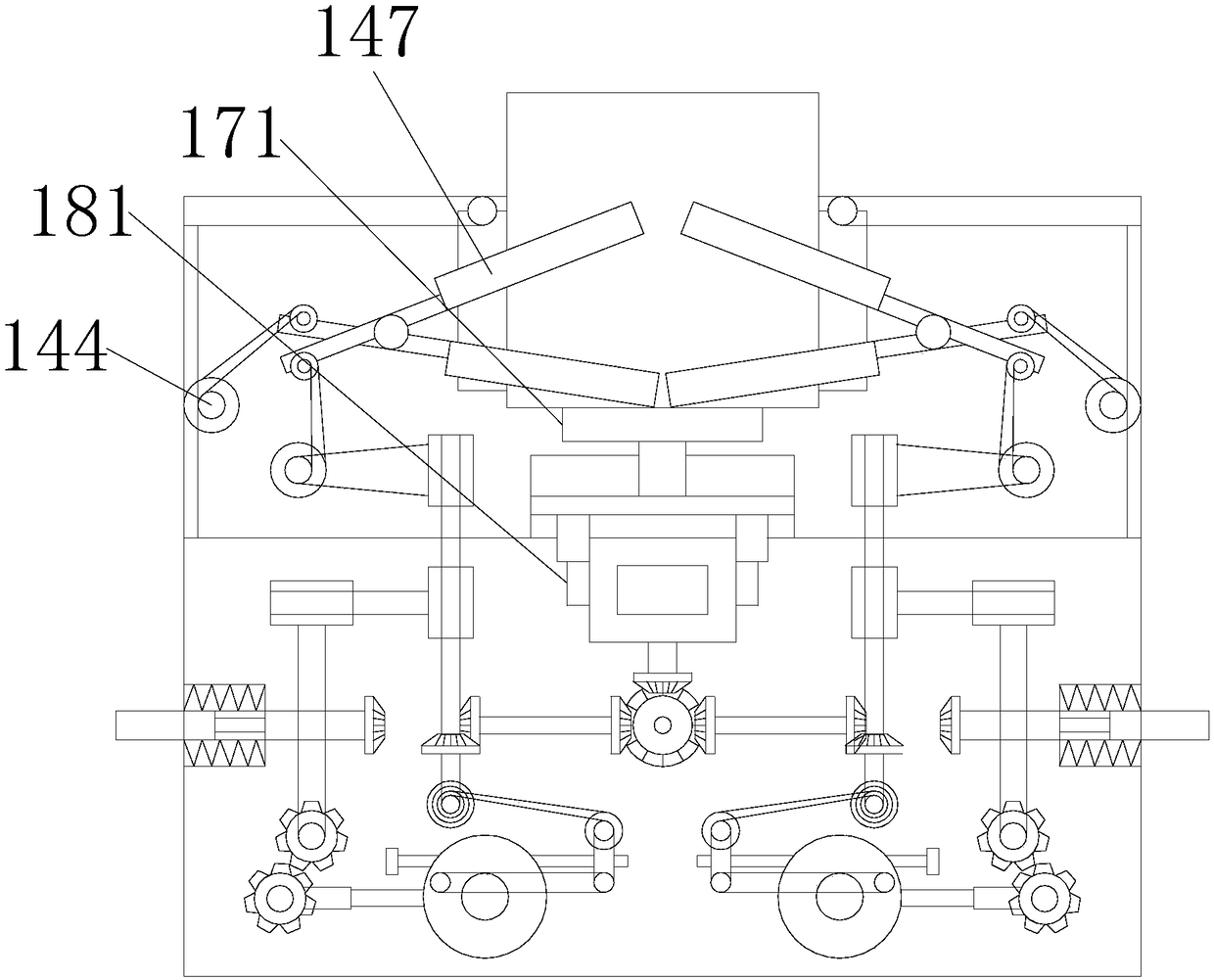

[0026] see Figure 1-Figure 5 , the present invention provides a lathe turning processing internal expansion tooling, its structure includes a reinforced mobile mechanism 1, grabbing clip fixing seat 2, grabbing clip 3, mold notch 4, mold groove 5, engraving head 6, engraving base 7, fixed The base 8, the mounting hole 9, the mounting buckle 10, the grasping clip fixing seat 2 is set on the fixed base 8 to drive, and the described fixing base 8 and the grabbing clip fixing seat 2 are an integrated structure;

[0027] A grab clip 3 is provided at the top of the grab clip holder 2, the grab clip 3 and the grab clip fix seat 2 adopt clearance fit, and a mold notch 4 is installed on the right side of the grab clip 3 , the mold slot 4 is located in the mold slot 5 to drive, the mold slot 5 and the mold slot 4 are an integrated structure, the right side of the mold slot 5 is equipped with an engraving base 7, and the engraving base 7 The top is provided with an engraving head 6, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com