Laser marking method, laser marking equipment and system

A laser marking method and technology of laser marking equipment, which are applied in the field of laser marking, can solve problems such as inability to adapt to product conveying speed and low laser marking efficiency, so as to increase the effective marking range, improve efficiency, and improve accuracy rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

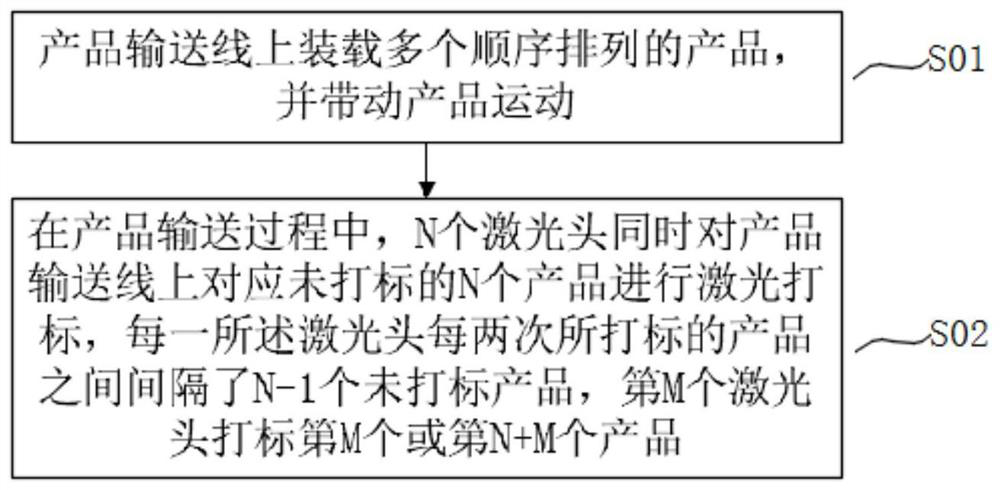

[0037] Such as figure 1 As shown, the present invention provides a preferred embodiment of a laser marking method.

[0038] A laser marking method, comprising the steps of:

[0039] Step S01, loading a plurality of sequentially arranged products on the product conveying line, and driving the products to move.

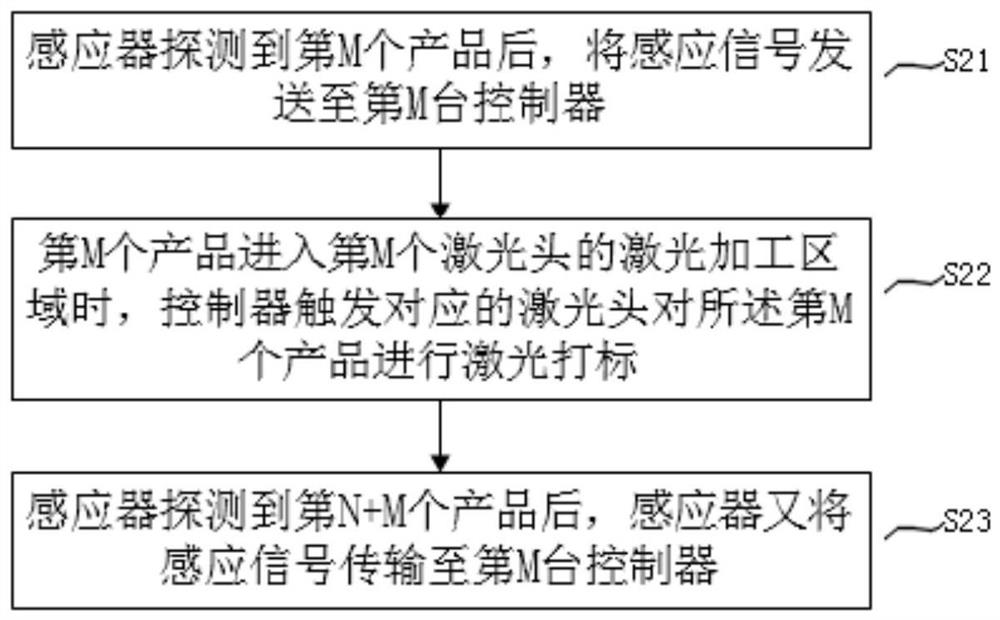

[0040] Step S02. During the product conveying process, N laser heads perform laser marking on the corresponding unmarked N products on the product conveying line at the same time, and the products marked by each laser head every two times are separated by For N-1 unmarked products, the Mth laser head marks the Mth or N+Mth product.

[0041] Among them, N≥3, M≤N, and M is a positive integer, such as 1, 2, 3....

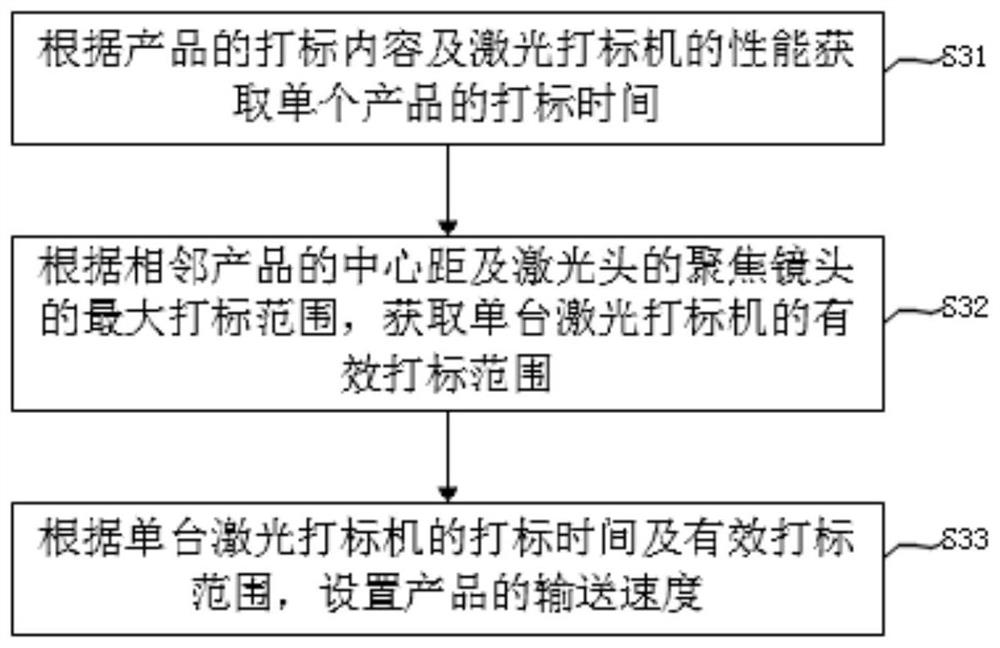

[0042] Through the laser marking method, for some small-sized products, when the center distance between adjacent prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com