Novel light guide plate assembly device

A technology for assembling devices and light guide plates, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as cumbersome operations and increased equipment procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

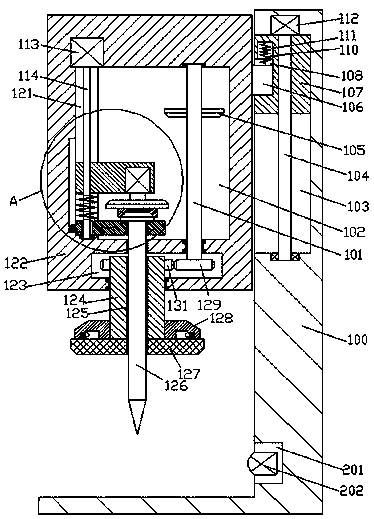

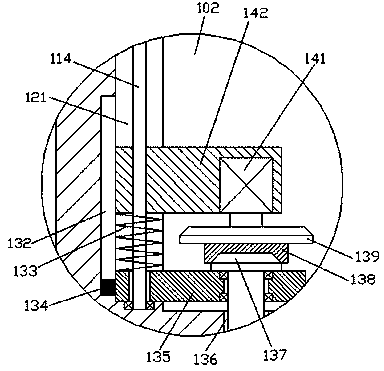

[0015] Combine below Figure 1-5 The present invention will be described in detail.

[0016] refer to Figure 1-5 , a new light guide plate assembly device according to an embodiment of the present invention, comprising a support frame 100, an outer shell 122 is provided on the left side of the support frame 100, and a first transmission cavity 123 is arranged inside the outer shell 122, so A rotary cylinder 124 is installed in the bottom wall of the first transmission chamber 123 for rotation. The extension section at the bottom of the rotary cylinder 124 protrudes from the bottom end surface of the outer casing 122 and the bottom end is provided with a grinding device. The top of the rotary cylinder 124 The extension section penetrates into the first transmission cavity 123 and the outer periphery is fixed with a first gear 131, and the drum 124 is provided with a first opening 125 up and down, and a drill bit is installed in the first opening 125 with clearance 126, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com