Diameter-adjustable shaping drum suite

An adjustable drum kit technology, applied in metal processing and other directions, can solve the problems of troublesome operation and long time, and achieve the effect of improving production efficiency and shortening adjustment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

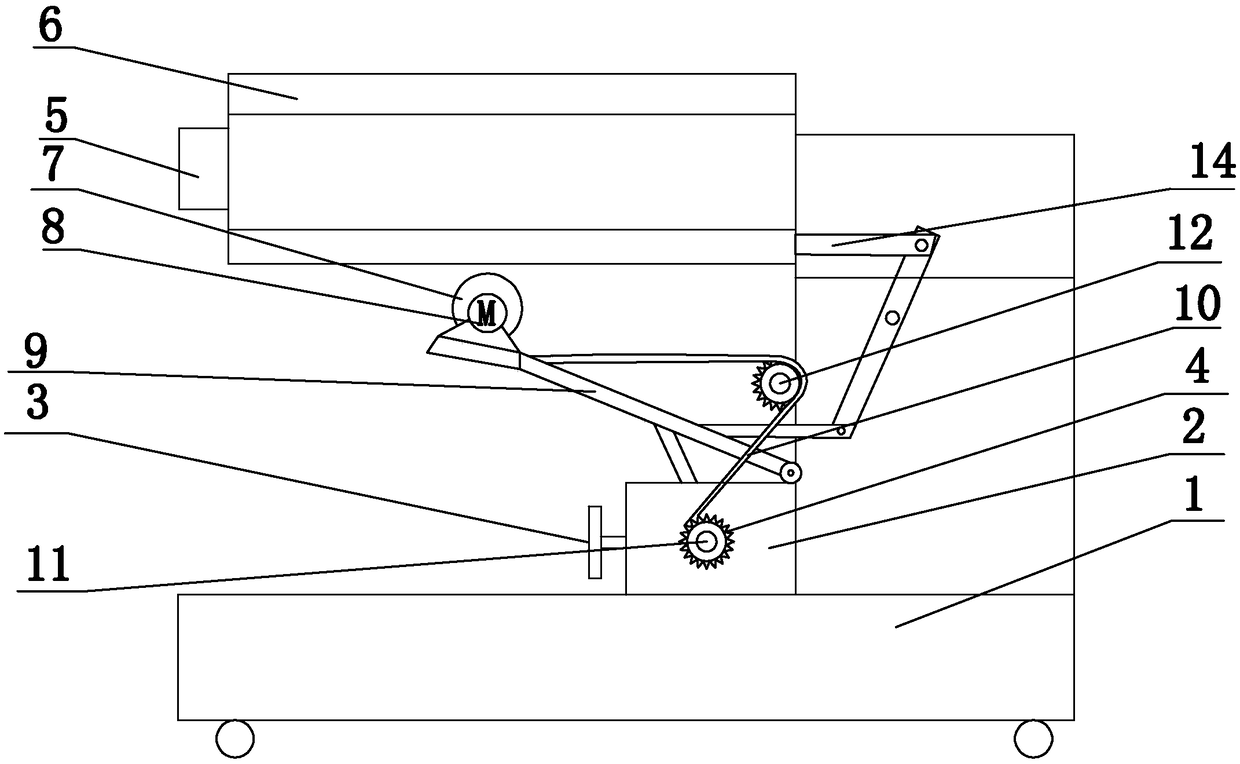

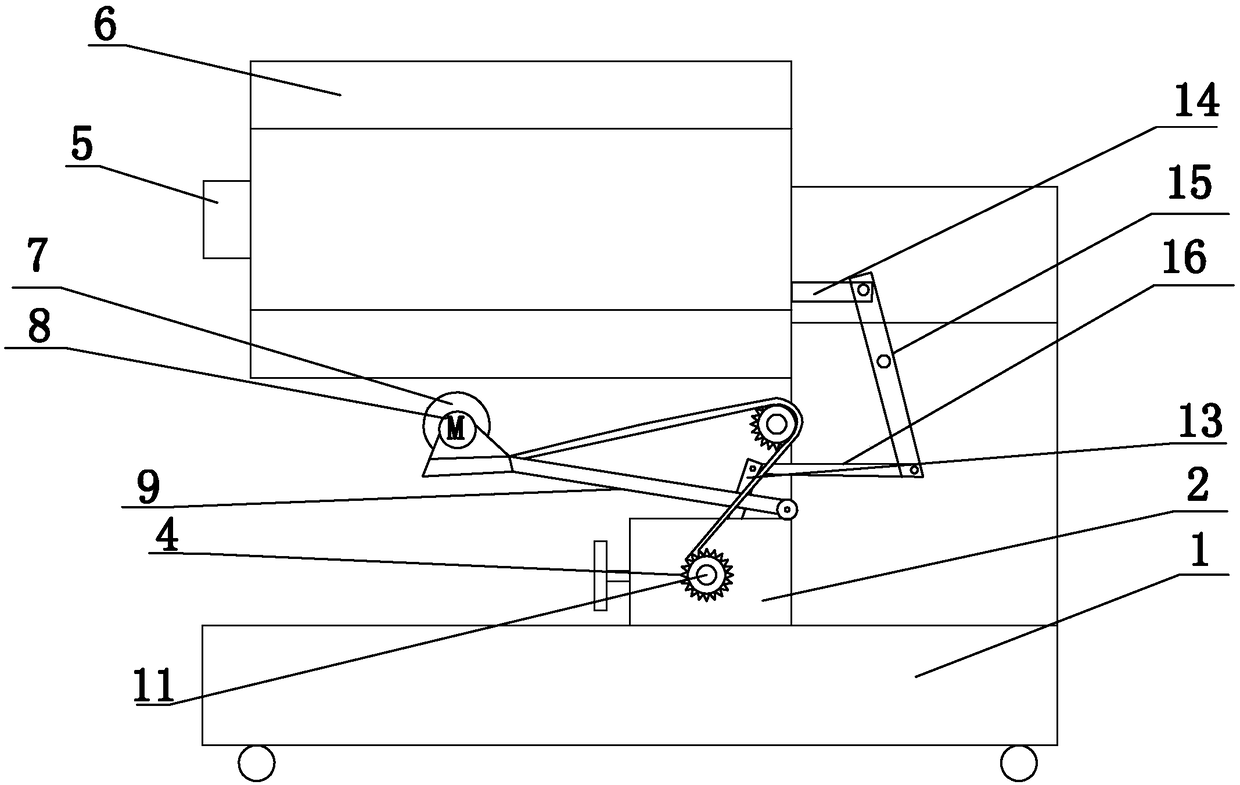

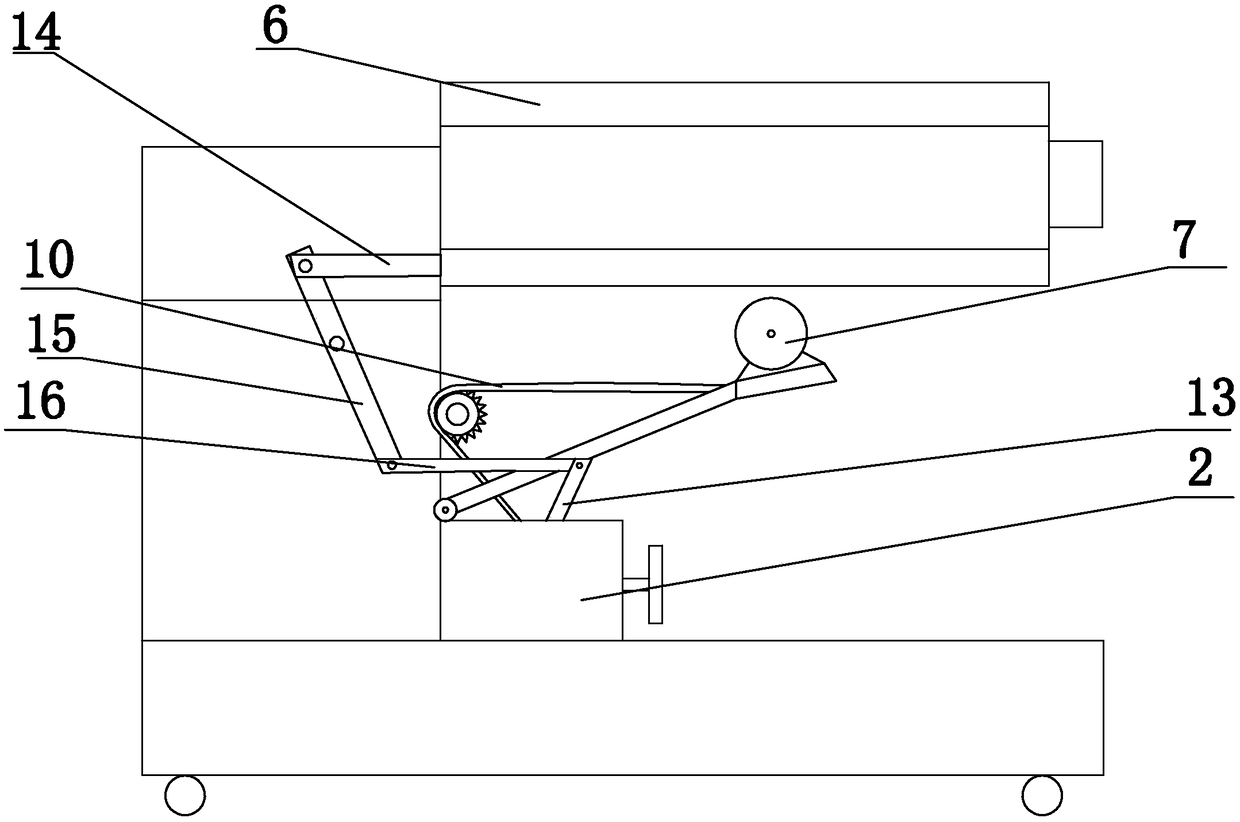

[0020] The present invention is described in further detail below:

[0021] The present invention provides a diameter-adjustable shaping drum kit, which includes a frame 1, a shaping drum, a cutter mechanism and a power mechanism, and is characterized in that the power mechanism includes a transmission 2 and a hand crank 3, and the hand crank 3 and the transmission 2 The input shaft is connected, and the output spindle 11 of the transmission 2 is fixed with a sprocket 4. The said shaping drum includes a guide tube 5 and a plurality of tile-type expansion sheets 6. The guide tube 5 is a hollow cylindrical structure. One end is fixedly connected with the frame 1, and a drive frame is provided between the guide cylinder 5 and the tile-type expansion piece 6 to stretch the tile-type expansion piece 6 outward or inwardly, and is connected between the output spindle 11 and the transmission frame There is a connecting rod assembly that drives the movement of the transmission frame; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com