Cube satellite plug-and-play reed type structure modularized assembling structure and method

A structural module, plug-and-play technology, applied to artificial satellites, transportation and packaging, aerospace equipment, etc., can solve the problems of reducing satellite payloads, intelligent connection devices with many parts, and large sizes, so as to facilitate popularization and use, Easy and fast assembly, expanding the effect of diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

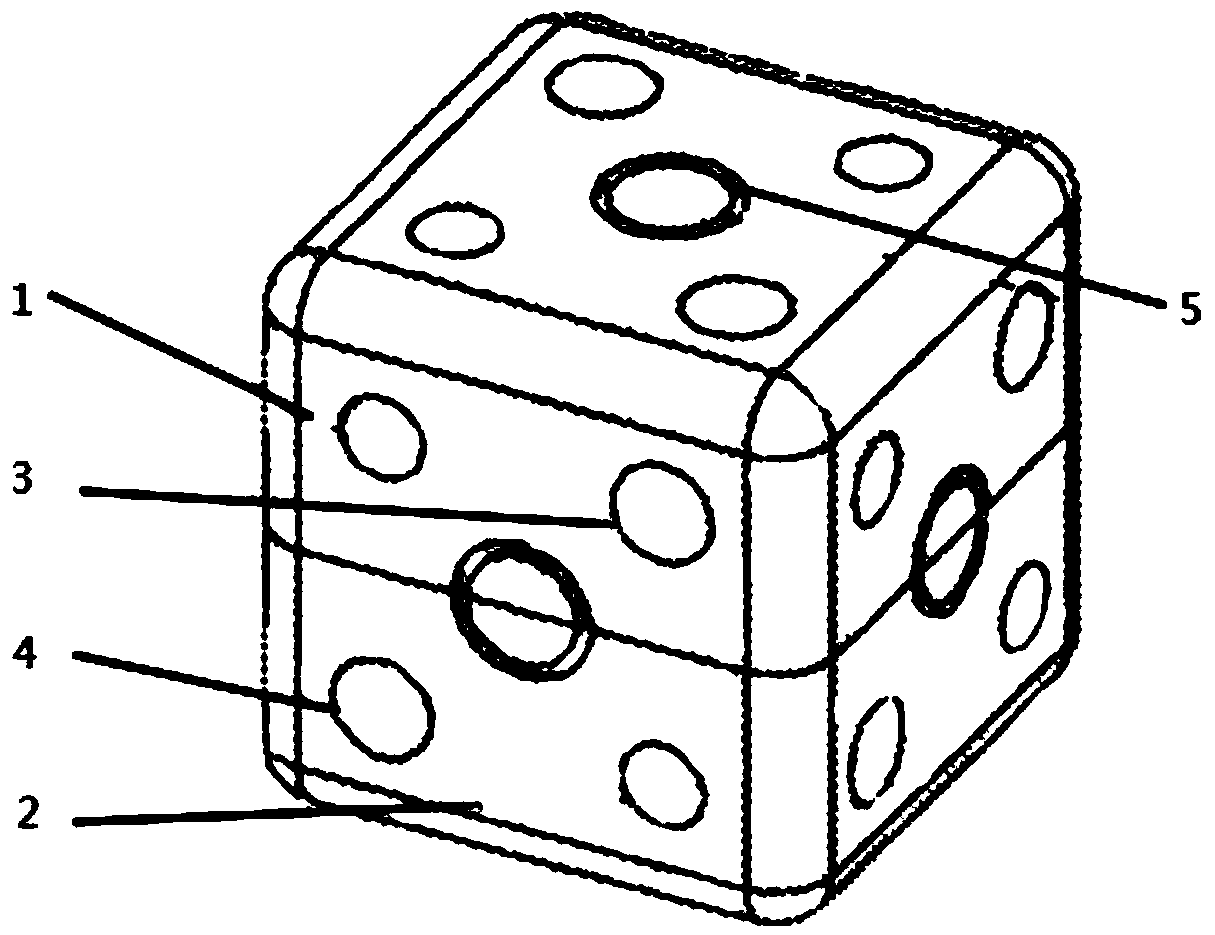

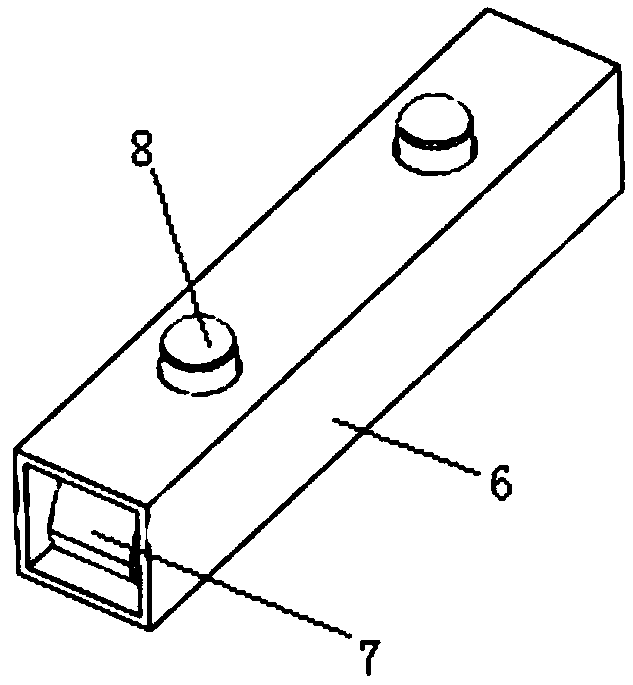

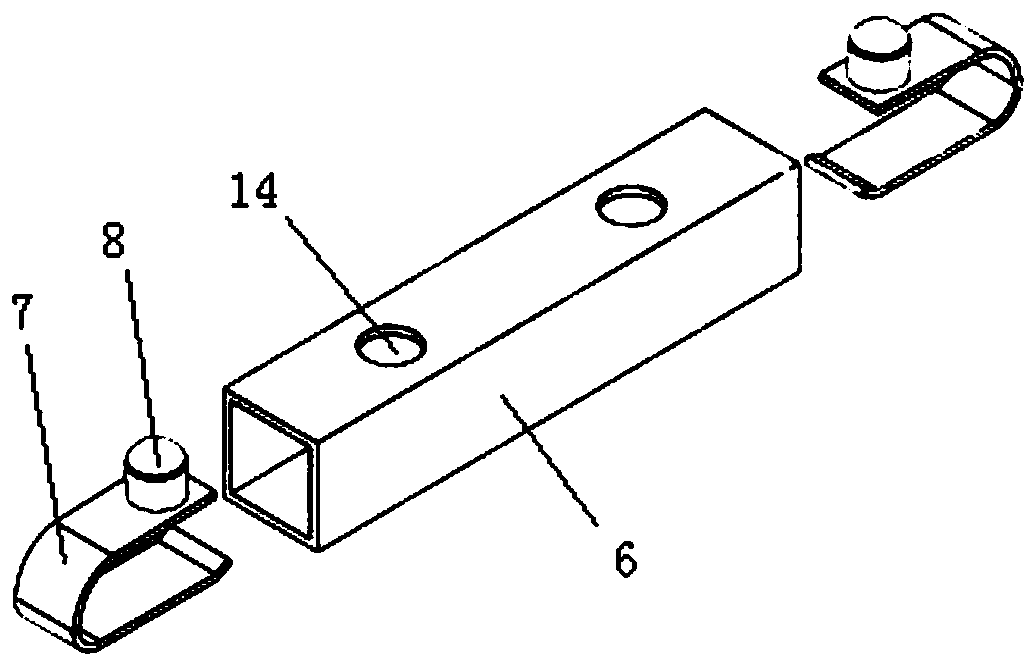

[0024] Such as Figure 2-Figure 5 Shown, a kind of Cubestar plug-and-play reed structure modular assembly structure of the present invention, comprises at least two Cubestars, Cubestar comprises Cubestar frame 13, and each Cubestar frame 13 is made of twelve prisms 131 A rectangular parallelepiped frame structure is formed, the upper prism and the lower prism of the left and right end faces of the rectangular parallelepiped frame structure are respectively provided with rectangularly distributed female interfaces 11 along the longitudinal direction, and the four left and right end faces of the rectangular parallelepiped frame structure The center of the prism is respectively provided with a female interface 11 perpe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap