Online can sealing module

A technology of can molds and cans, applied in the field of online can sealing modules, can solve problems such as low work efficiency and lack of production competitiveness, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

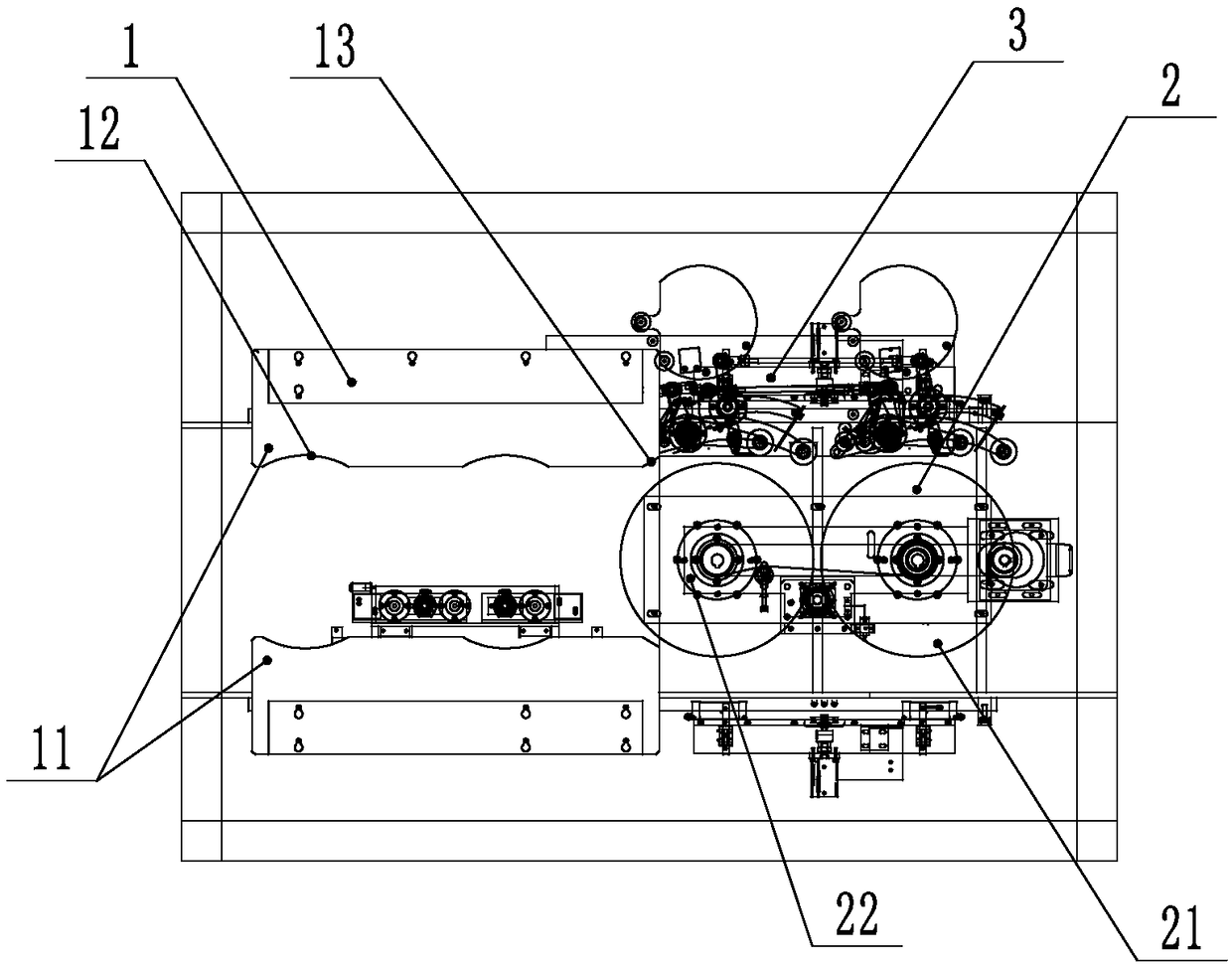

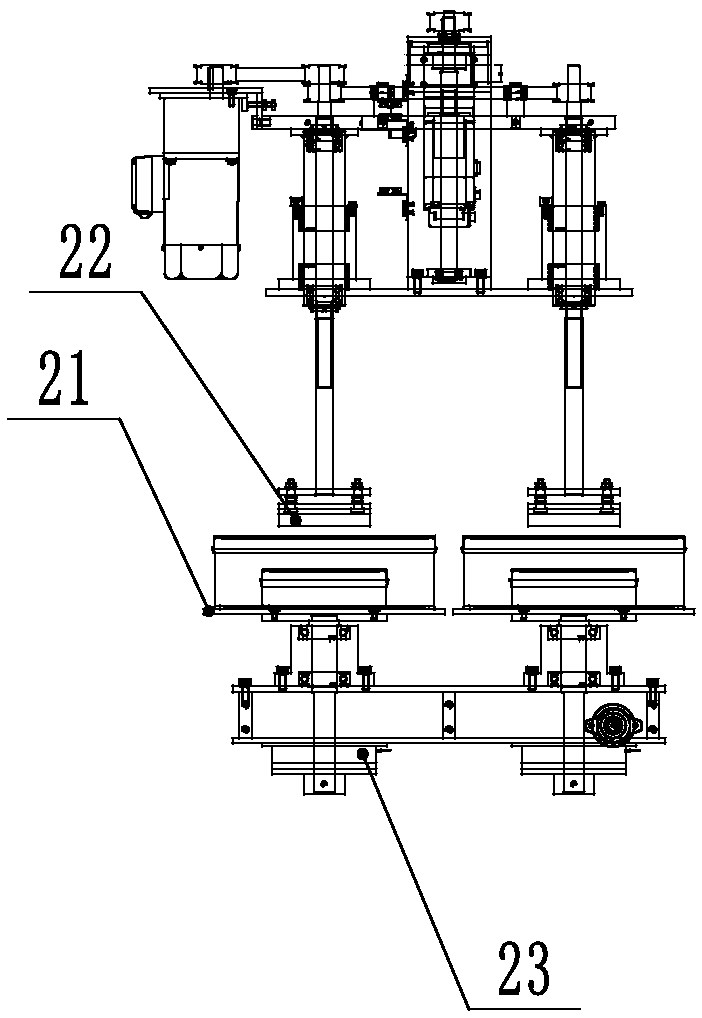

[0033]In the process of continuous work, when the cans are rotated under the drive of the turntable 21 and the sealing is completed, the splint 11 holds the new cans and enters the turntable 21. If the turntable 21 is still rotating, it will make the cans that have just entered the turntable 21 The jar rotates thereupon, but at this moment the briquetting block 22 does not press the jar tightly. If it is light, it will cause serious deviation of the jar, and if it is heavy, the jar will fly out of the turntable 21. Therefore, as a preferred embodiment, the The bottom of the turntable 21 is provided with an electromagnetic brake 23 for stopping the rotation of the turntable 21. Effectively, after the sealing process of the can is completed, the electromagnetic brake 23 is used to stop the turntable 21 from rotating. Enter on the turntable 21, and push out and recycle the jars that have been sealed.

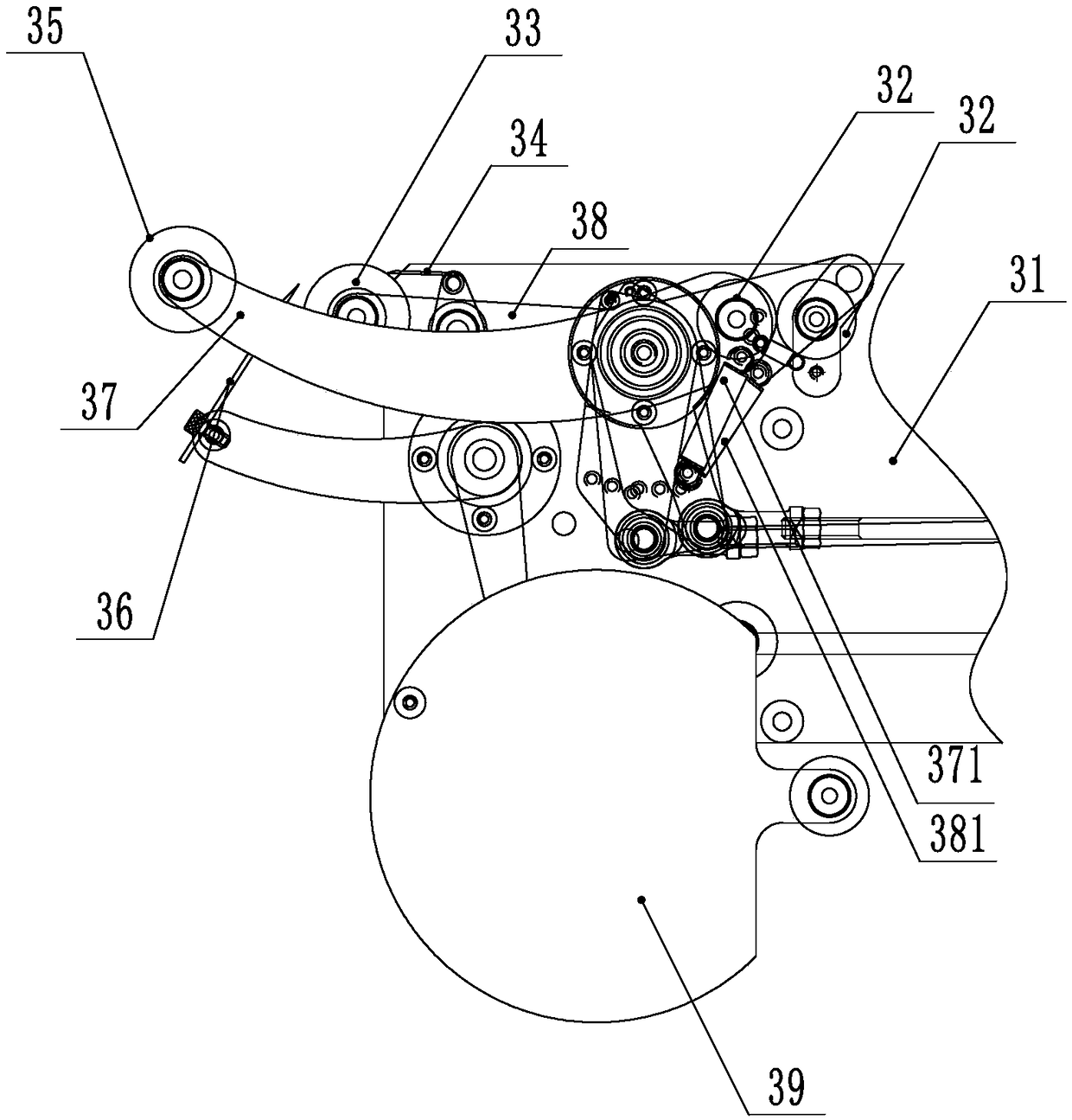

[0034] refer to figure 1 and figure 2 , the gluing mechanism 3 also include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com