Precise lifting mechanism for installation of large valve

An installation and valve technology, applied in the direction of lifting devices, lifting frames, hand-held tools, etc., can solve problems such as difficult alignment of positions, tiring and troublesome lifting of valves, etc., to reduce manual labor and facilitate manual installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

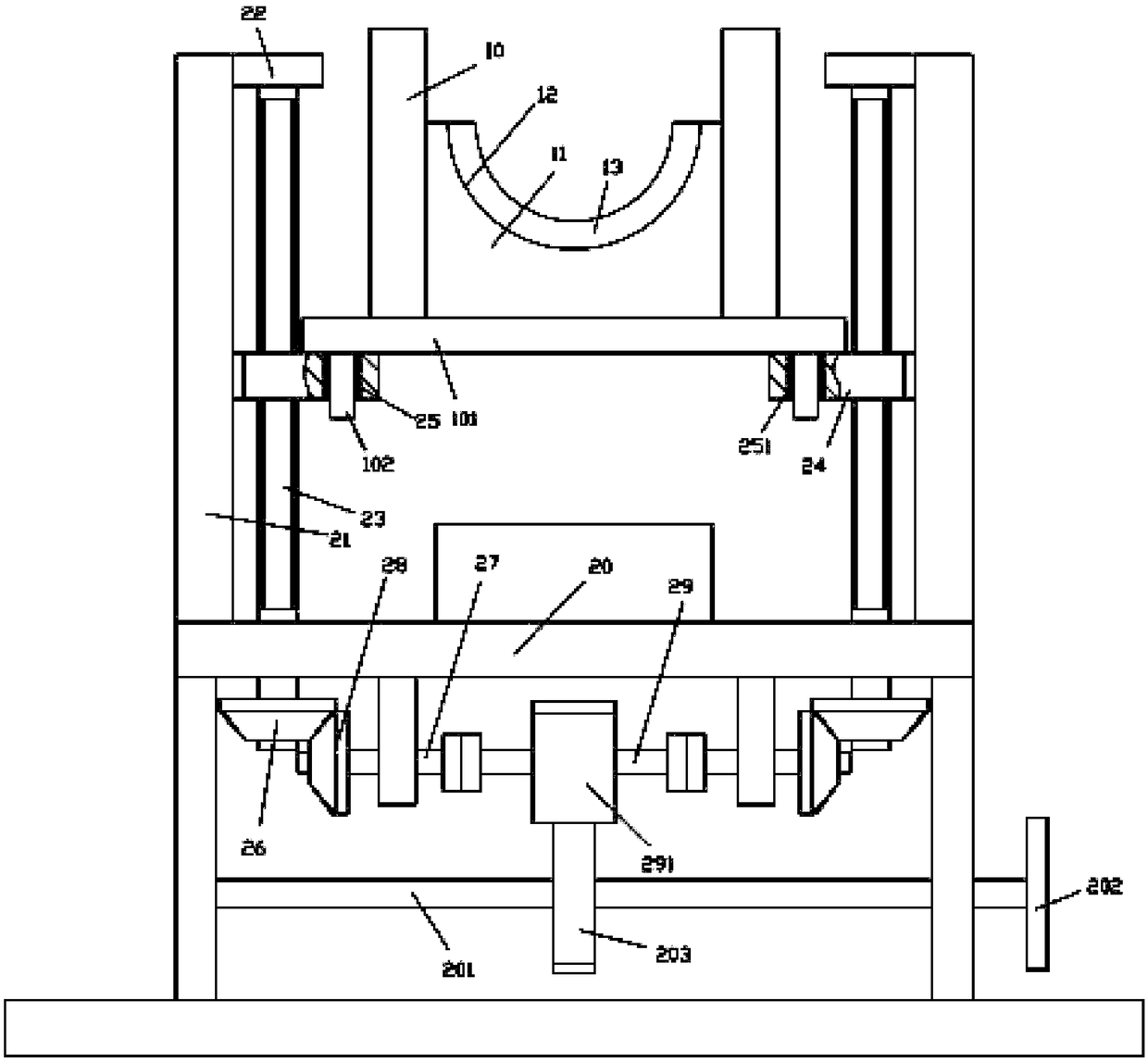

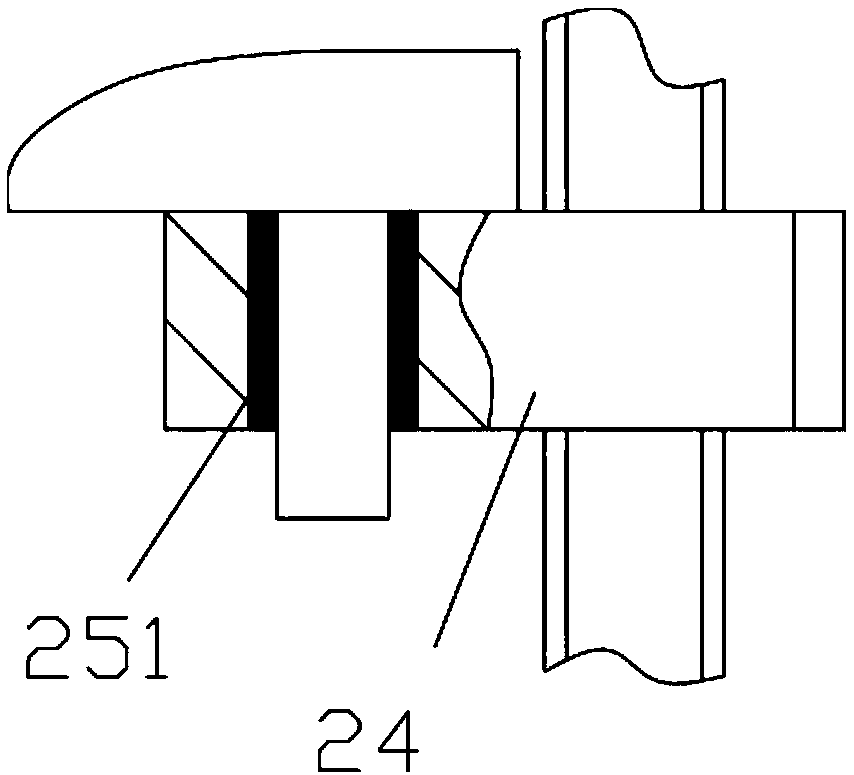

[0014] Examples, see e.g. Figure 1 to Figure 2 As shown, a precision lifting mechanism for large-scale valve installation includes an underframe 20, vertical support plates 21 are fixed on the left and right sides of the top plate of the underframe 20, and the top inner walls of the two vertical support plates 21 are fixed Horizontal plate 22 is arranged, and two vertical screw rods 23 are positioned at the left and right sides of the top plate of bottom frame 20, and the bottom end of vertical screw rod 23 is hinged on the top plate of bottom frame 20, and the top end of vertical screw rod 23 is hinged on the horizontal plate 22 , the vertical screw 23 is screwed with a lifting block 24, the bottom surface of the main base plate 101 is pressed against the top surfaces of the two lifting blocks 24, the left and right sides of the main base plate 101 are fixed with vertical guide columns 102, and the vertical guide columns 102 The sleeve is inserted into the positioning throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com