Reinforcement testing and optimizing method based on compaction effect

An optimization method and compaction pile technology, which can be applied in field foundation soil survey, foundation structure engineering, construction, etc., can solve the problems of non-growth, etc., and achieve small disturbance of pile body, no influence of pile body density, and fast measurement time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

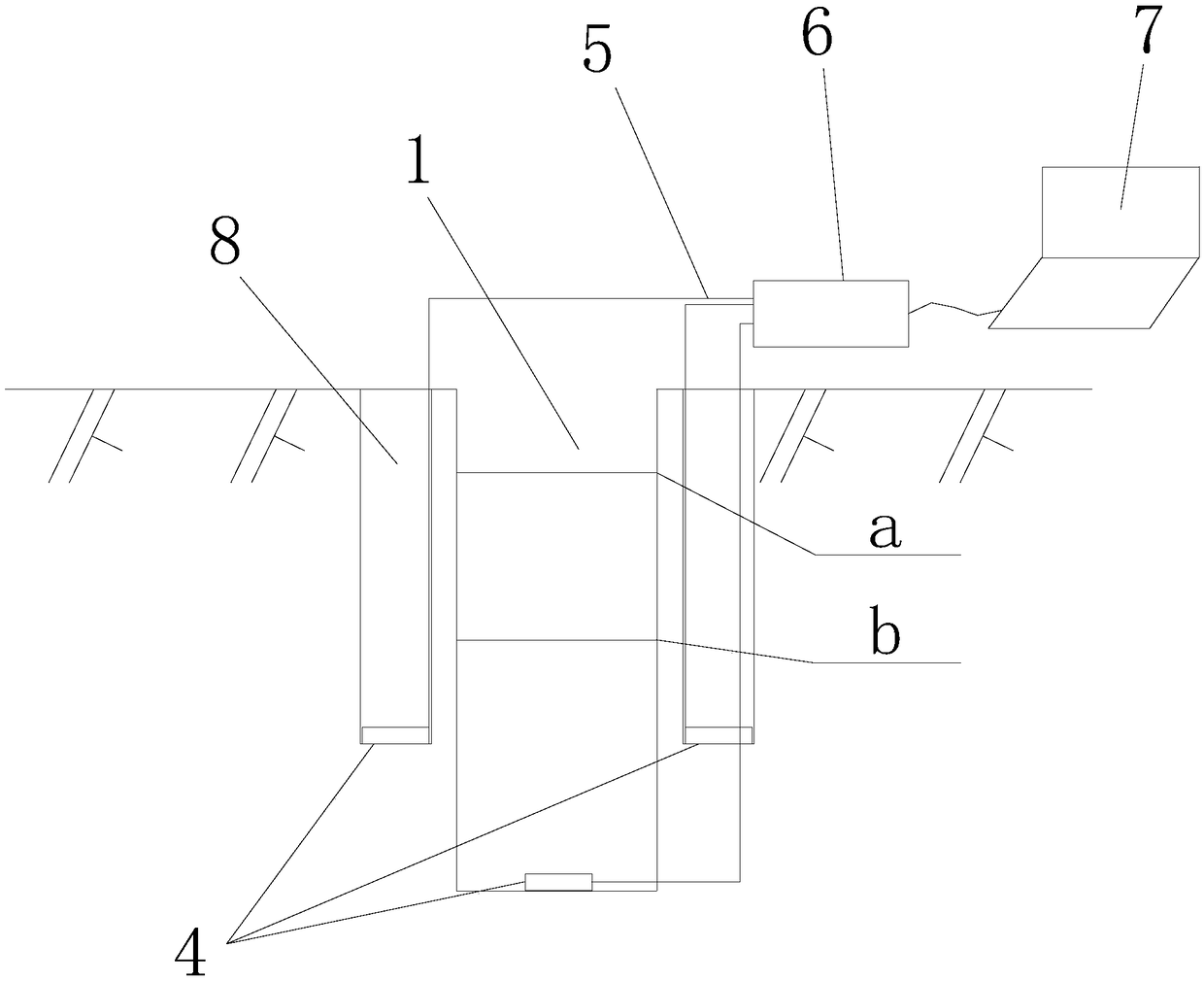

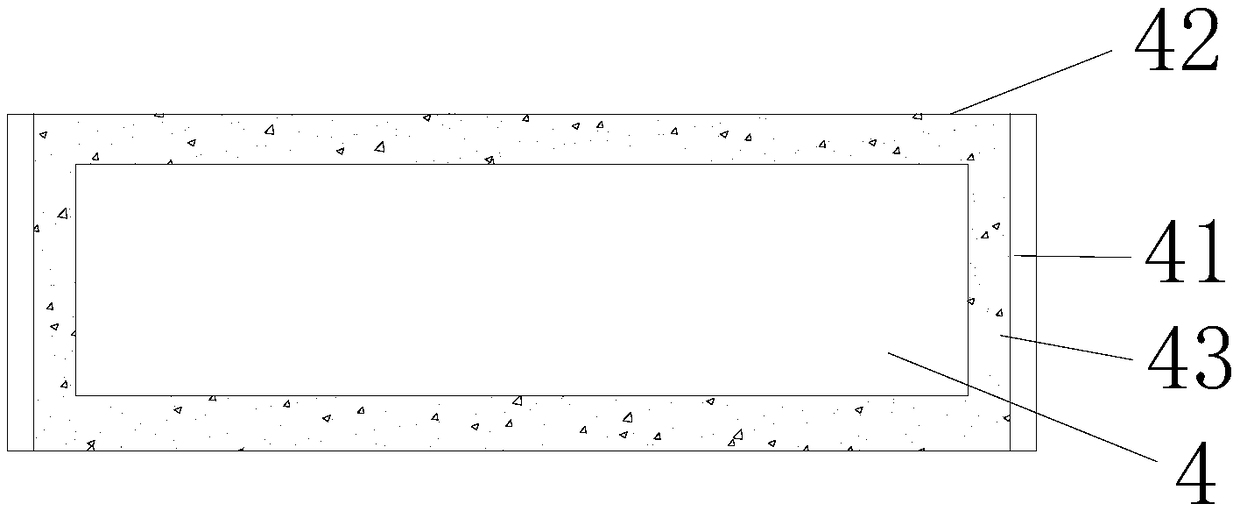

[0080] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

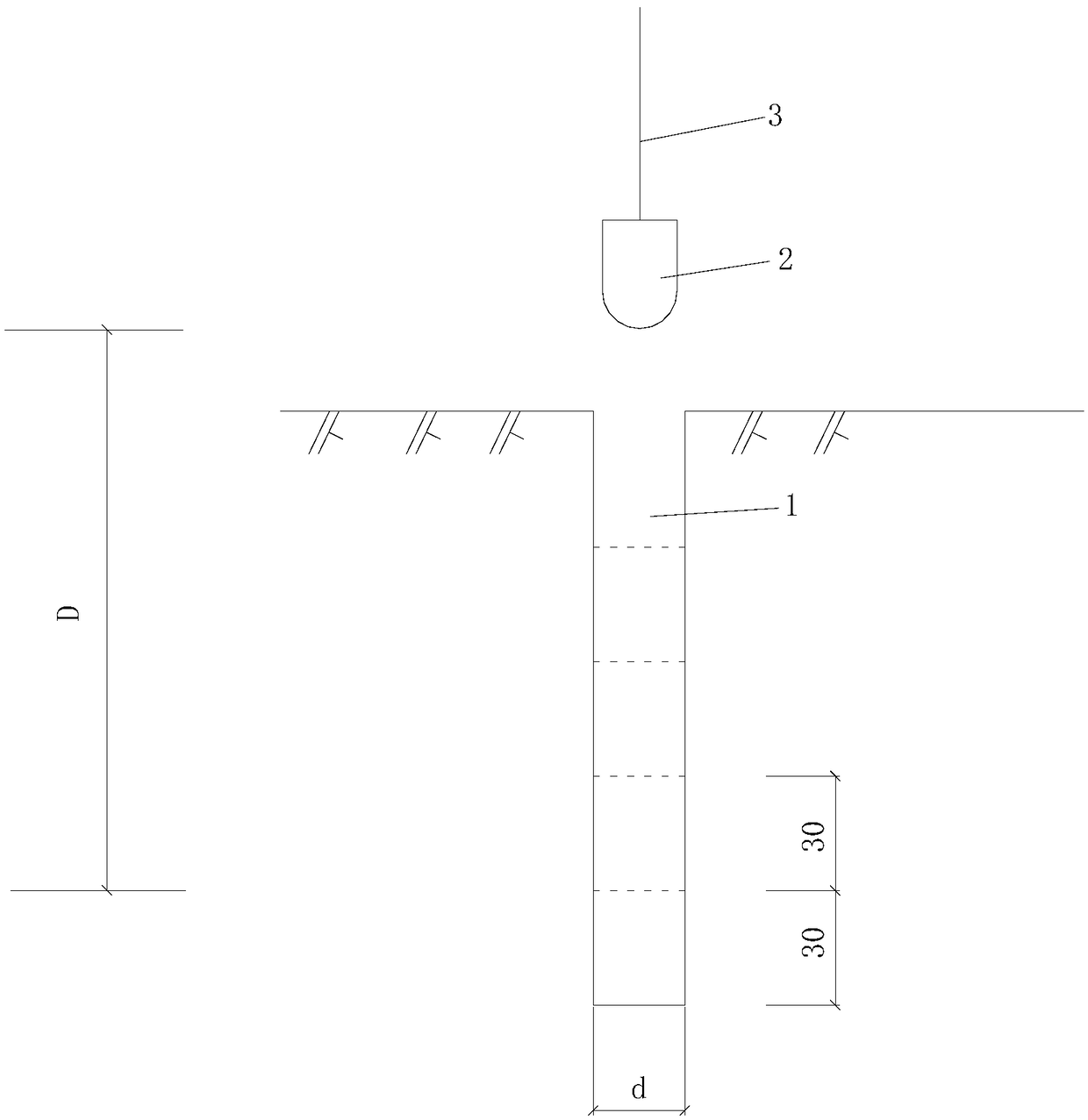

[0081] Please refer to Figure 1-9 , the described reinforcement test and optimization method based on the compaction effect includes the following steps:

[0082] 1. Test model design

[0083] In the reinforcement of existing railways, the soil-cement compaction pile relies on drilling a hole in the existing railway subgrade, filling the hole with a mixture of cement and plain soil, and using a rammer to compact it into a soil-cement compaction pile. The pile is compacted under the action of the rammer, and at the same time, the original soil around the pile is compacted to both sides, so that the bearing capacity of the soil around the pile is improved, and the compaction coefficient of the pile body is also increased to increase the bearing capacity of the pile.

[0084] The present invention proposes to use the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com