Cross spherical roller bearing

A technology of spherical rollers and bearings, applied in the field of crossed roller bearings, which can solve problems such as unusable and limited bearing limit speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Exemplary embodiments of the present invention are described below with reference to the accompanying drawings. It should be understood that these specific descriptions are only used to teach those skilled in the art how to implement the present invention, but are not intended to exhaust all possible ways of the present invention, nor are they intended to limit the scope of the present invention.

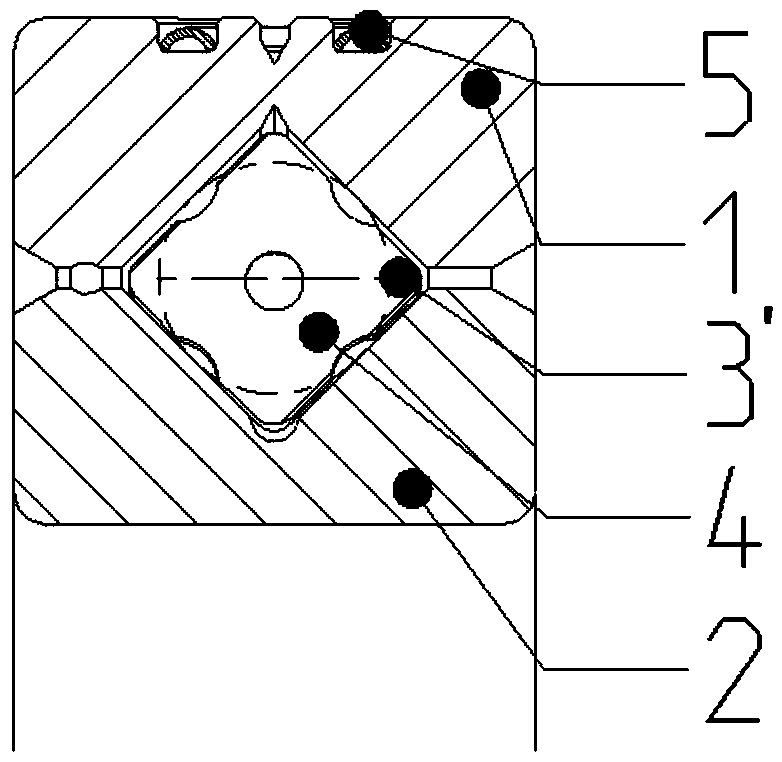

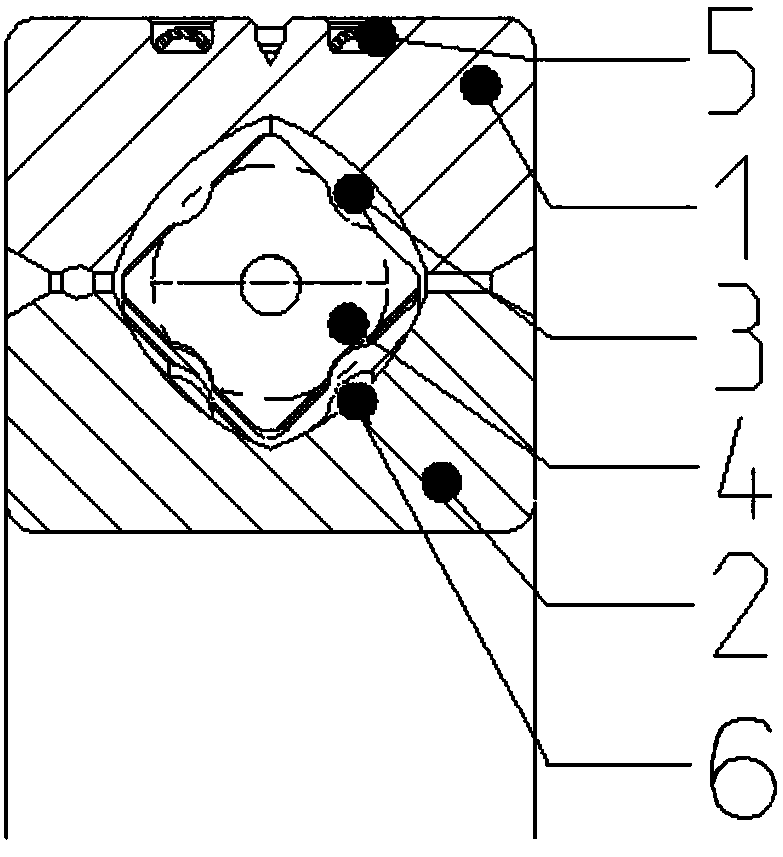

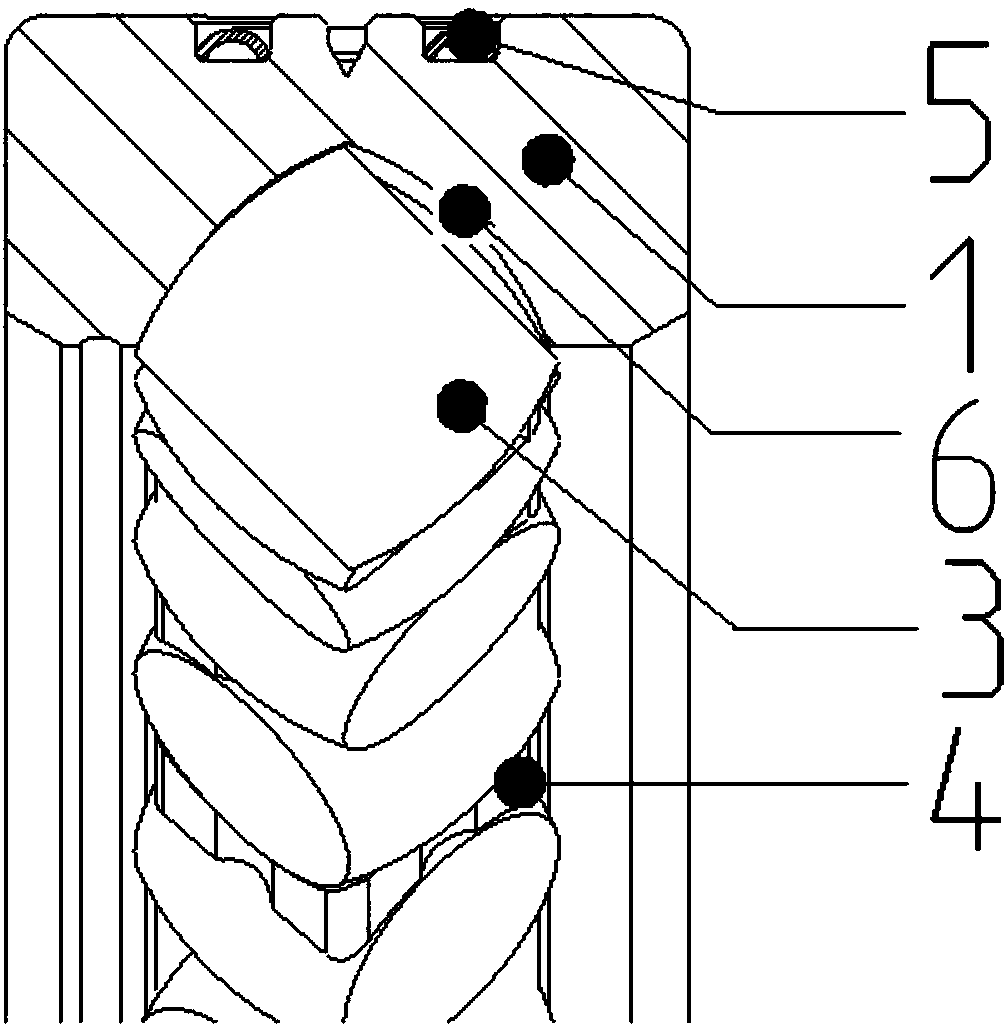

[0025] figure 2 is a sectional view of a crossed spherical roller bearing according to an embodiment of the present invention. Such as figure 2 As shown, the crossed spherical roller bearing is composed of outer ring 1, inner ring 2, spherical rollers (hereinafter also referred to as rolling elements) 3, spacer blocks 4 and lock rings 5. The rolling elements 3 are spaced and guided by spacer blocks 4 . The inner ring 2 is designed in one piece. The outer ring 1 has two halves in the circumferential direction. After the rolling elements 3 and the spacer blocks 4 are asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com