Automatic drainage joint

An automatic drainage and water outlet technology, applied in the direction of engine components, valve details, diaphragm valves, etc., can solve problems such as faucet freezing, achieve the effect of preventing faucet from freezing, enriching functions, and preventing water pipes from freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

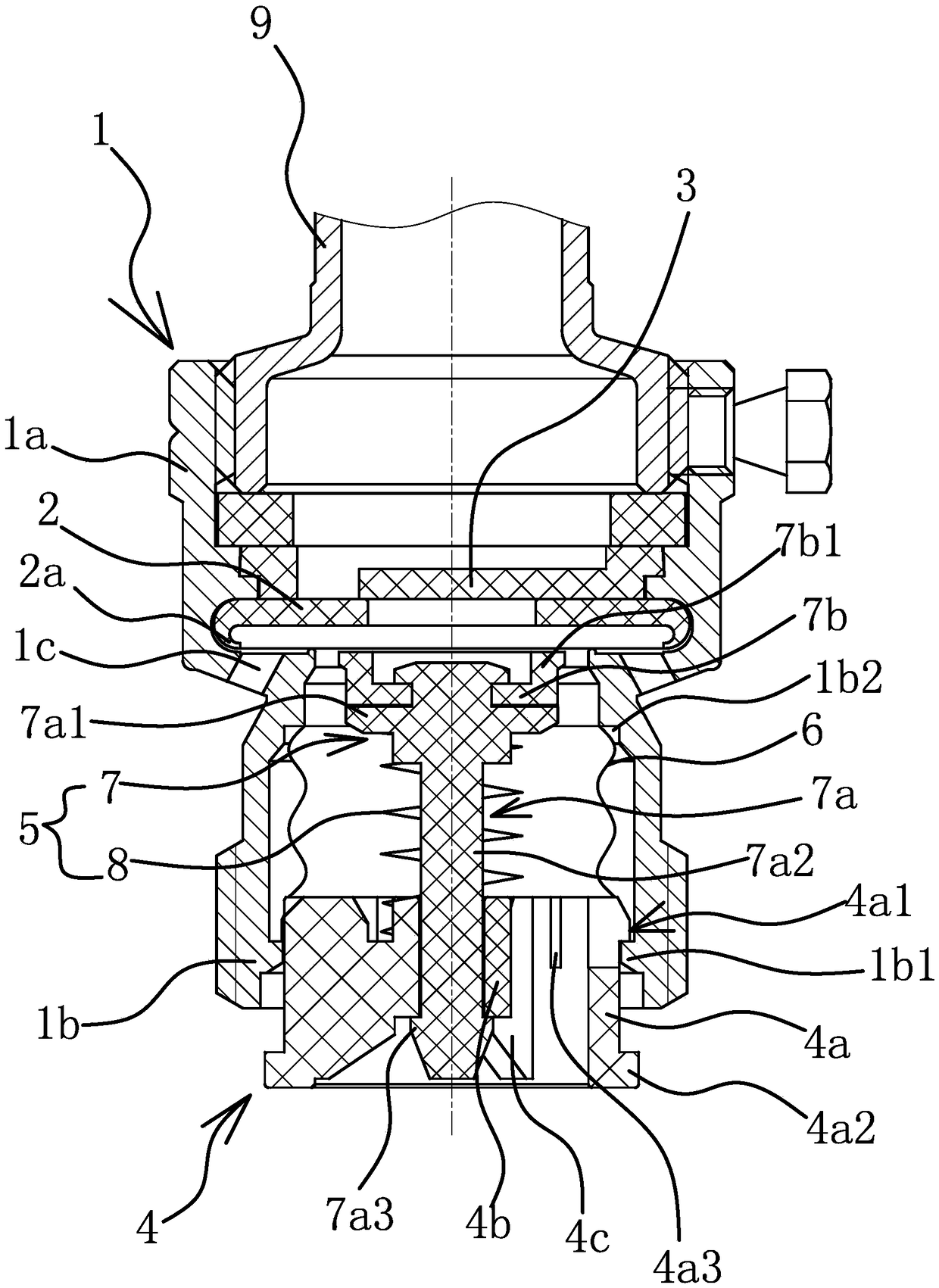

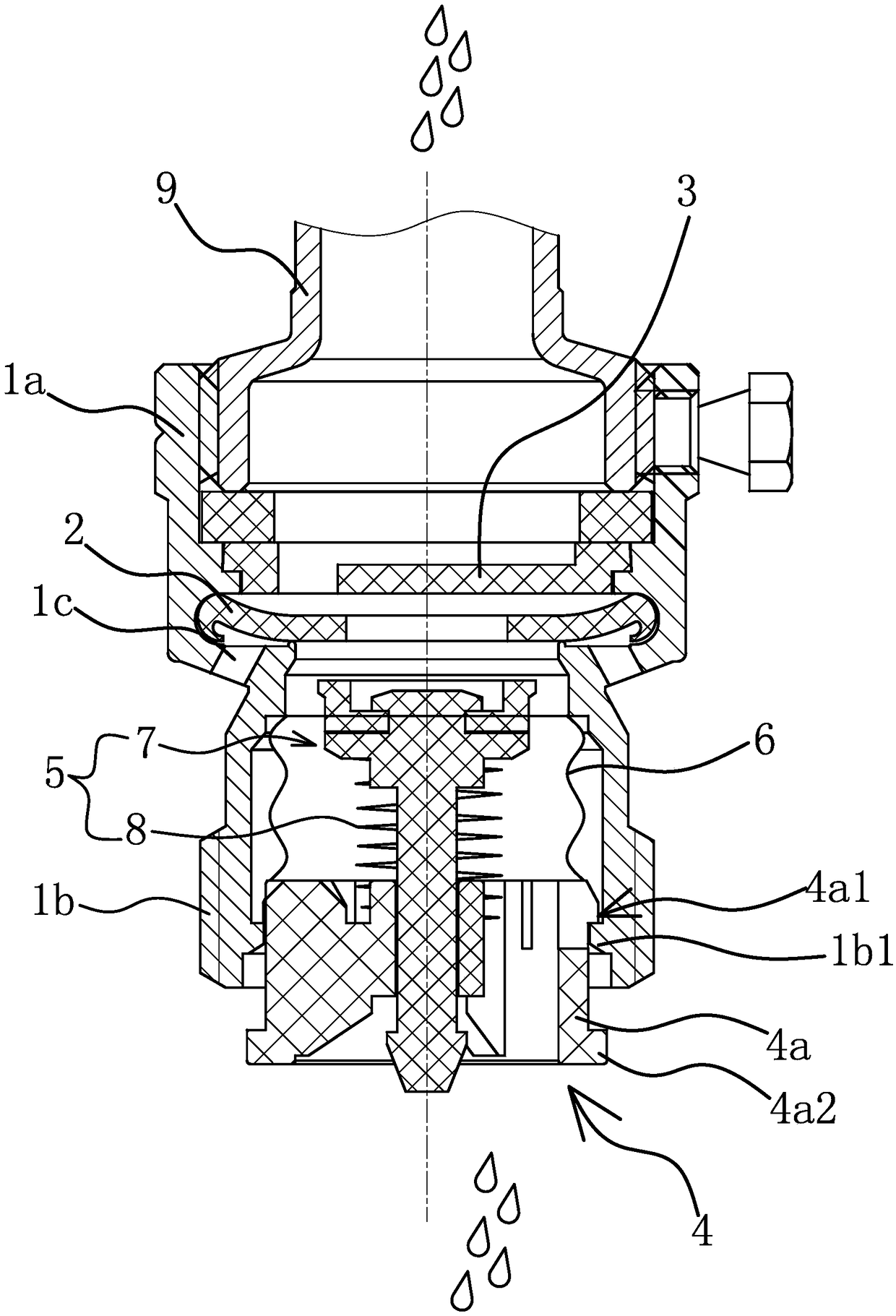

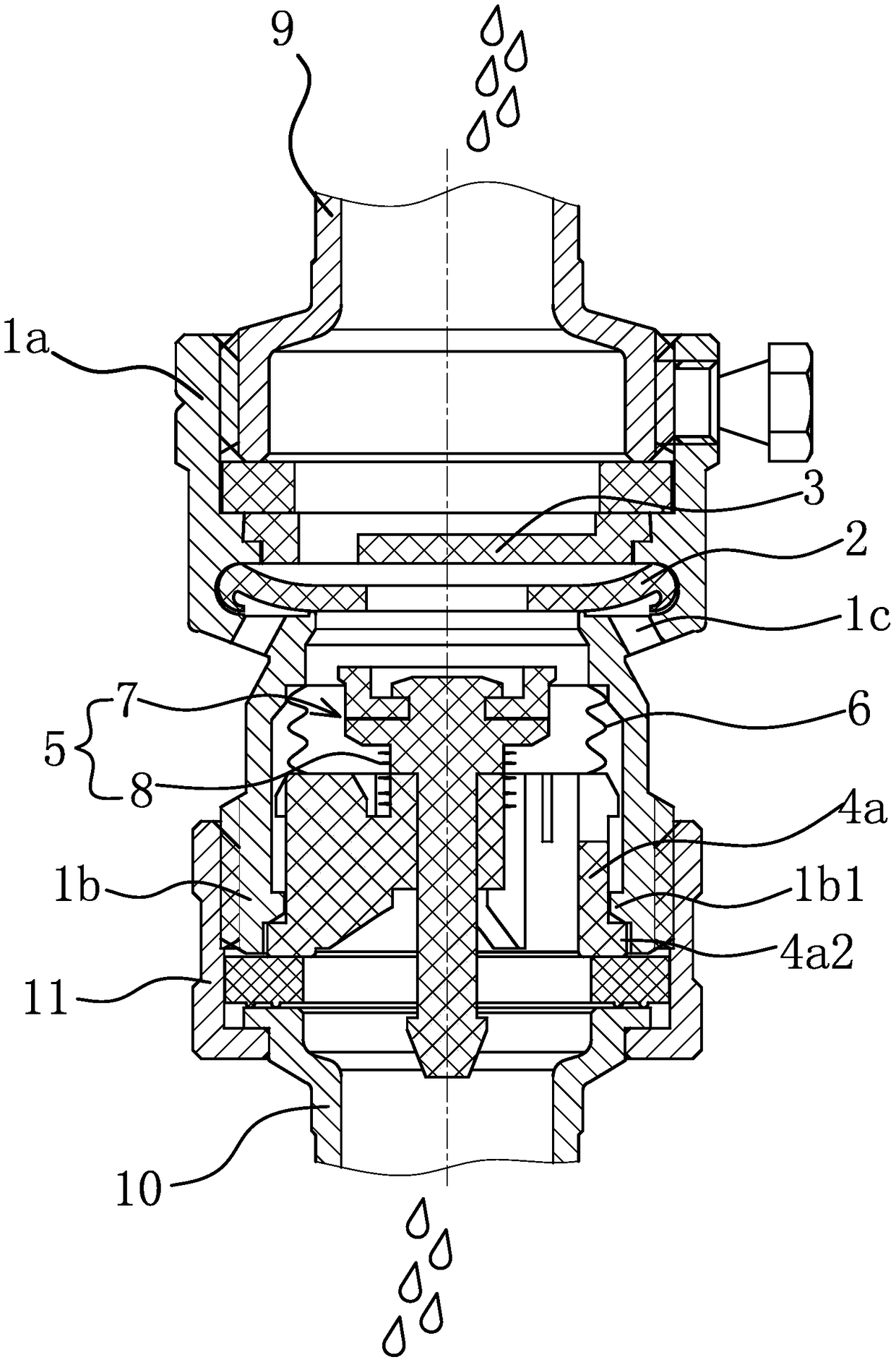

[0038] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, an automatic drainage joint includes a body 1. The upper end of the body 1 is a water inlet 1a for connecting with a faucet 9. A locking hole is provided through the outer side of the water inlet 1a, and the inner thread of the locking hole is connected with a locking hole. Screw, when installing, put the water inlet 1a of the body 1 outside the water outlet of the water tap 9, then tighten the locking screw to fix the body 1 on the water outlet of the water tap 9. The lower end of the main body 1 is the water outlet 1b used to connect with the water pipe 10, and the outside of the water outlet 1b has threads. When in use, the lock nut 11 is inserted outside the end of the water pipe 10, and the end of the water pipe 10 is offset against the end surface of the water outlet 1b. Rely on, and then screw the lock nut 11 on the thread on the outside of the water outlet 1b, so that the water pipe 10 and the bo...

Embodiment 2

[0051] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the support member 5 is a support spring, the lower end of the support spring is inserted on the guide column 4b, and the lower end surface of the support spring is against the on the upper end surface of each connecting piece 4c. The support member 5 is a support spring, the existence of each connecting piece 4c makes the setting of the ferrule 4 not affect the normal water outlet, and the setting of the guide post 4b enables the support spring to be inserted on the guide post 4b to form a connection with the ferrule 4, Therefore, the matching relationship between the support member 5 and the gasket 2 can be changed by changing the position of the ferrule 4, so that the automatic drainage joint can automatically discharge the residual water in the water pipe 10 when the water pipe 10 is connected to prevent the water pipe from 10 fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com