Combustor fire cover, combustor and gas stove

A burner and infrared burner technology, which is applied to the field of gas stoves, can solve the problems of energy saving, limitation of exhaust gas emissions, shortened service life of ignition needles and induction needles, etc., and achieves improved combustion efficiency, high utilization rate of heating area, and exhaust emission. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

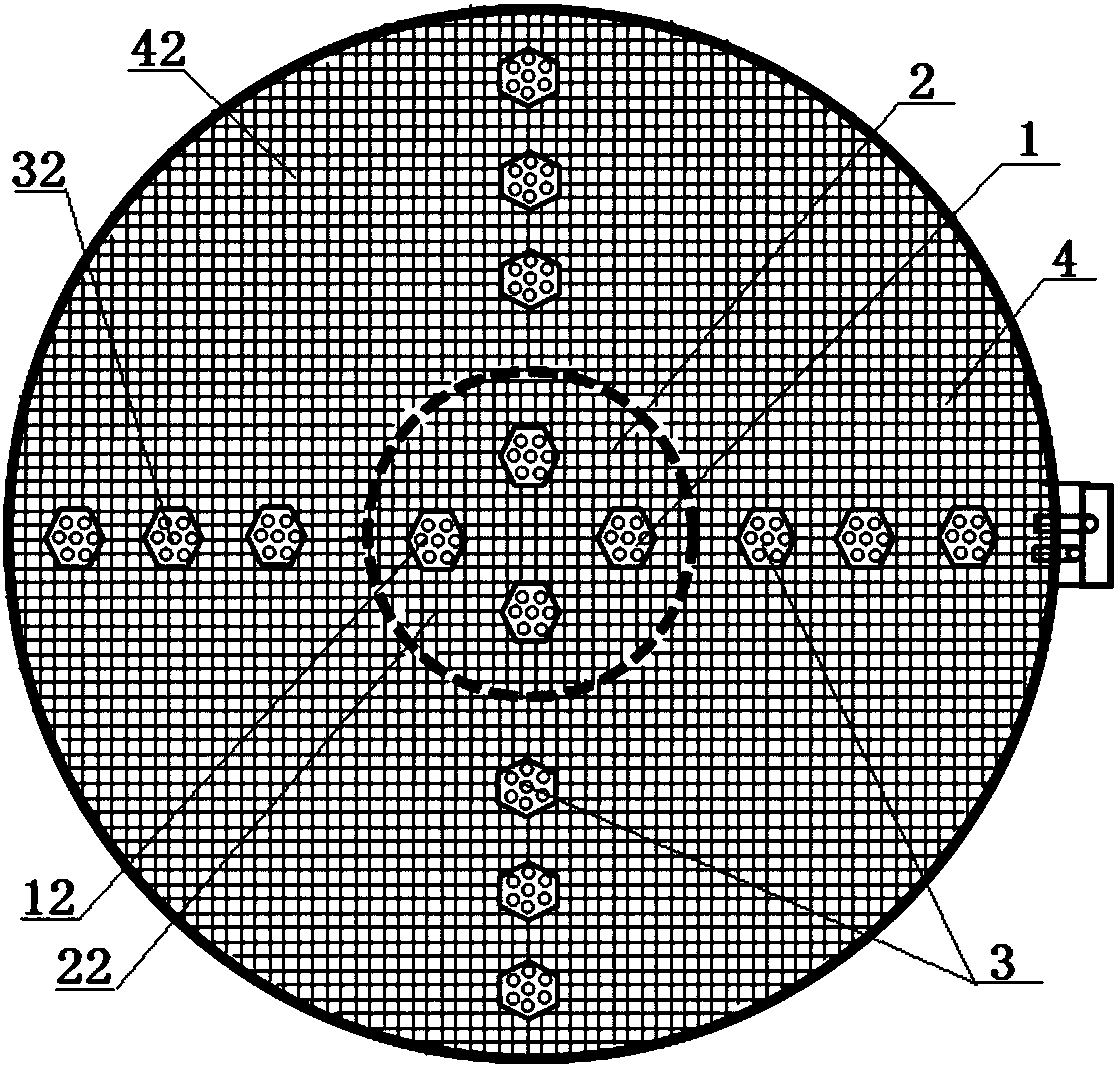

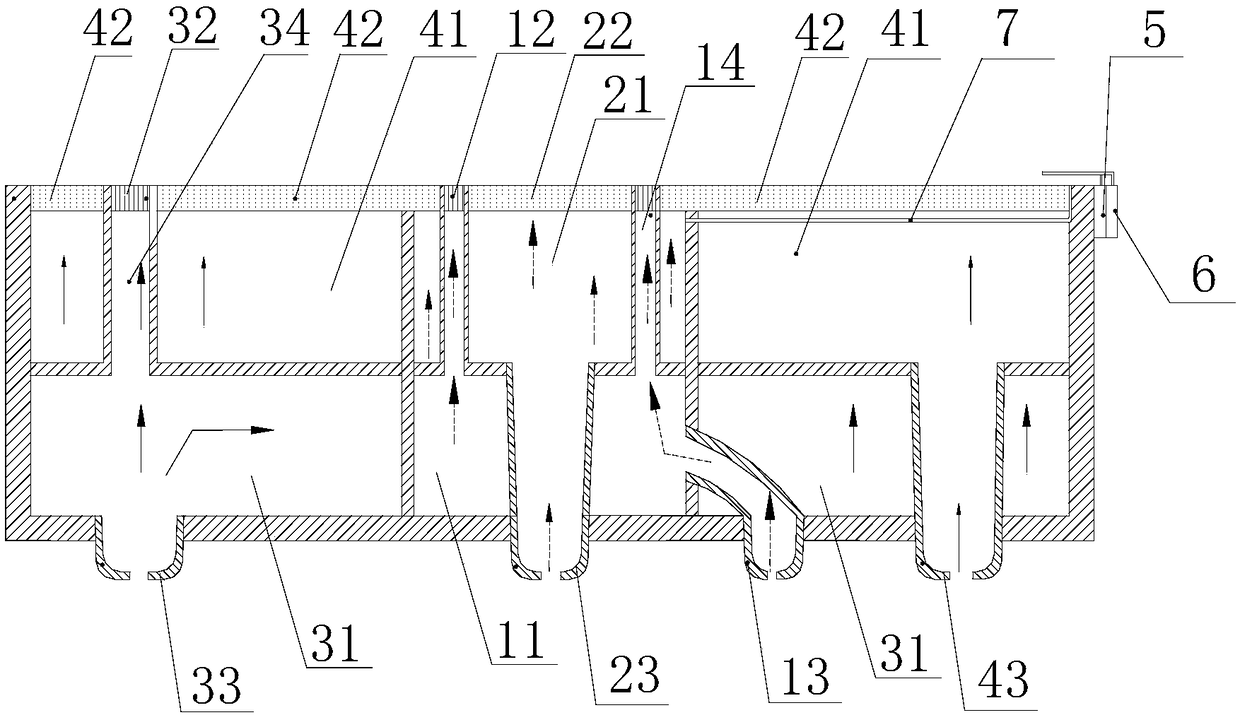

[0042] Such as figure 1 with figure 2 As shown, the present invention provides a burner, including an inner ring fire burner and an outer ring fire burner, at least one of the inner ring fire burner and the outer ring fire burner is composed of the first burner body and the second burner Body composition, wherein the first burner body is a partially premixed atmospheric burner, and the second burner body is a fully premixed infrared burner. The inner ring fire burner and the outer ring fire burner may also comprise only the first burner body or the second burner body.

[0043] In this embodiment, in order to improve the combustion efficiency and achieve better energy-saving efficiency, the burner preferably includes four burner bodies, which are respectively the first burner body 1 of the inner ring, the second burner body 2 of the inner ring, and the second burner body 2 of the outer ring. The first burner body 3 and the second burner body 4 of the outer ring, that is, the...

Embodiment 2

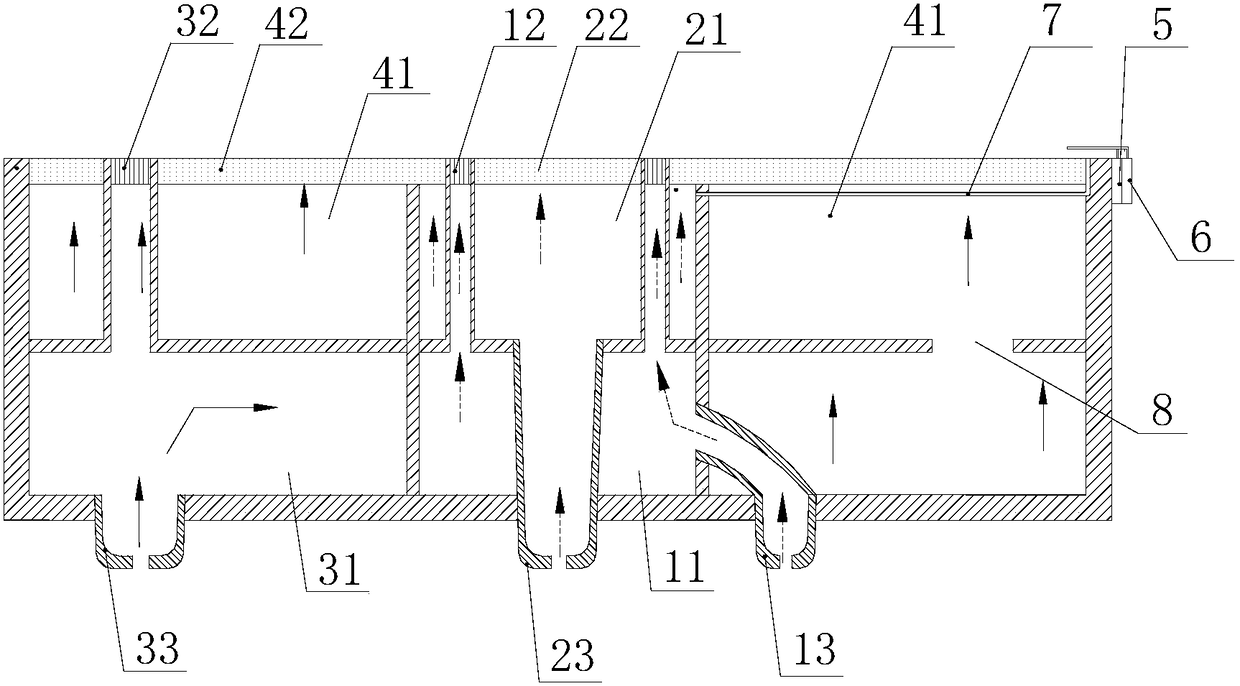

[0061] Such as image 3 As shown, the structure of the burner and burner cap in this embodiment is basically the same as that of Embodiment 1, the difference is that the first outer ring air mixing chamber 31 and the outer ring second air mixing chamber 41 are divided into upper and lower layers However, the first air mixing chamber 31 of the outer ring and the second air mixing chamber 41 of the outer ring communicate with each other through the vent 8, and only one vent 8 may be provided, or multiple vents 8 may be provided.

[0062] The first gas mixing chamber 31 of the outer ring communicates with the first injection pipe 33 of the outer ring, and the premixed gas is sprayed and burned from the first outer ring fire cover 32 at the top through a plurality of gas channels 34. The port 8 enters the second gas mixing chamber 41 of the outer ring on the upper layer, and sprays and burns from the second outer ring fire cover 42 on the top.

[0063] Since the first air mixing ...

Embodiment 3

[0065] Such as Figure 4 with Figure 5 As shown, the structure of the burner and the burner fire cover in this embodiment is basically the same as that of Embodiment 1, the difference is that the center of the inner ring fire burner has a central through hole 9 that penetrates up and down, and the inner ring first The second fire cover 22 is arranged around the central through hole 9 , and the ignition pin 5 and the induction pin 6 are installed in the central through hole 9 . Since the ignition needle 5 and the induction needle 6 are arranged at the center of the burner cap, there is no need to additionally arrange the permanent flame channel 7 in the first embodiment.

[0066] The burner fire cover of the inner ring fire and the burner fire cover of the outer ring fire in this embodiment are still an integral structure, wherein, the second fire cover 22 of the inner ring and the second fire cover 42 of the outer ring are the same infrared combustion plate, the combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com