Roasting plate using mica heating plate

A heating plate and fire oven technology, applied in the field of fire ovens, can solve the problems of affecting the service life of the heater, inconvenient operation for users, waste of electric energy resources, etc., and achieve the effects of fast heating speed, long service life, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

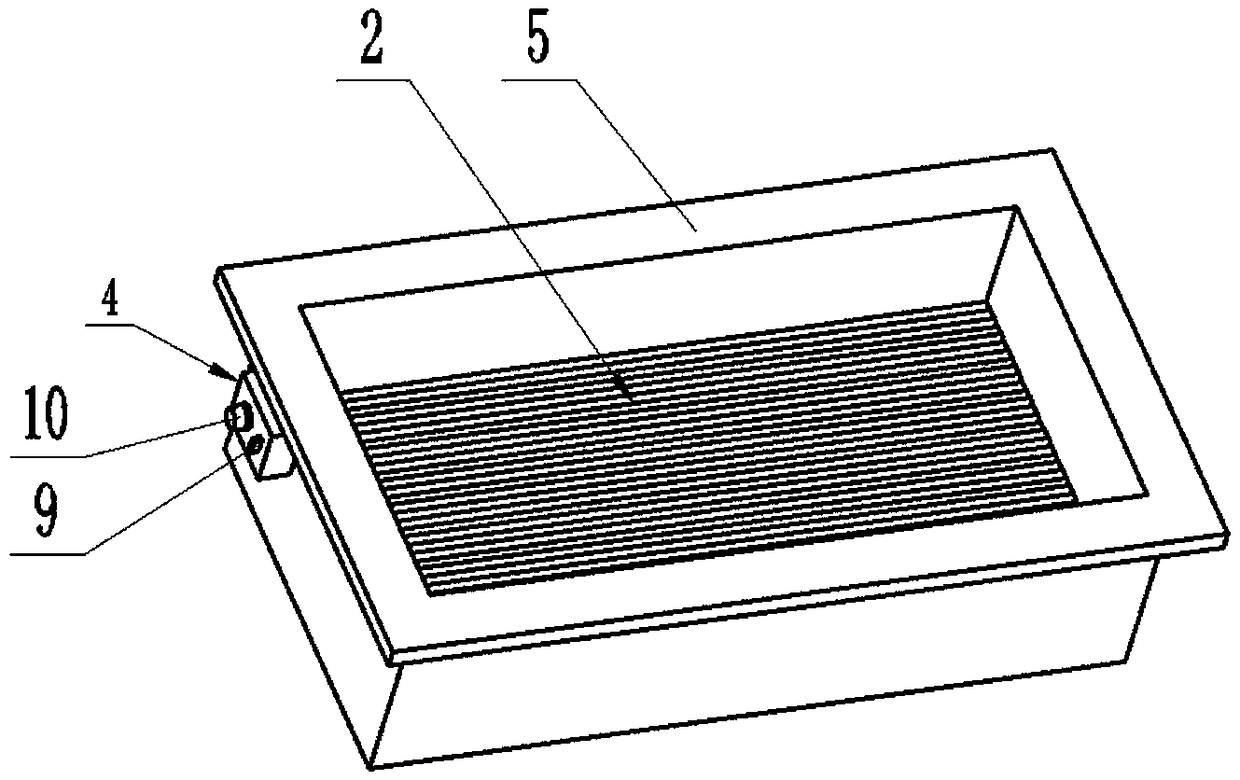

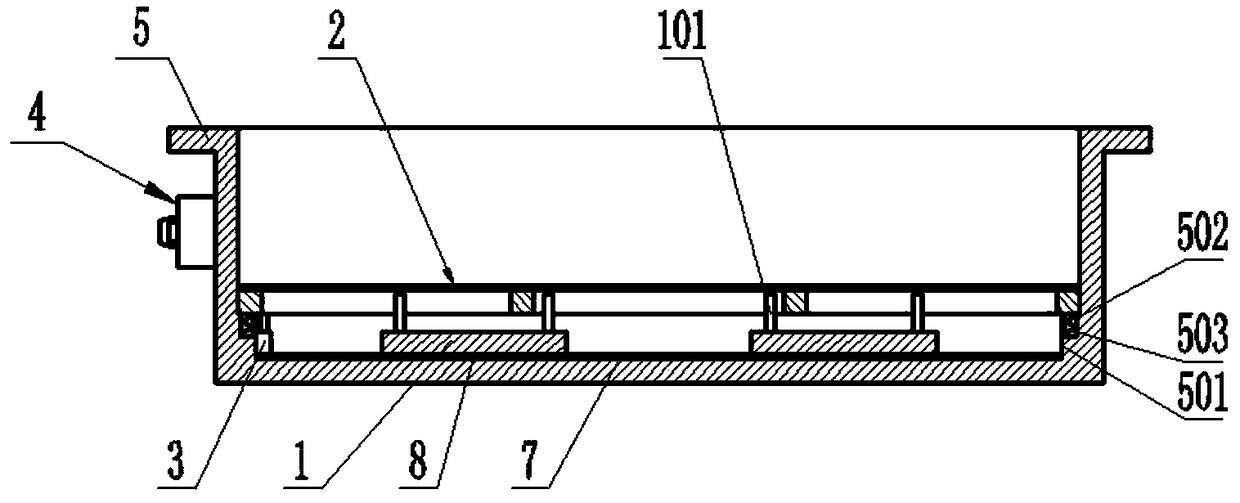

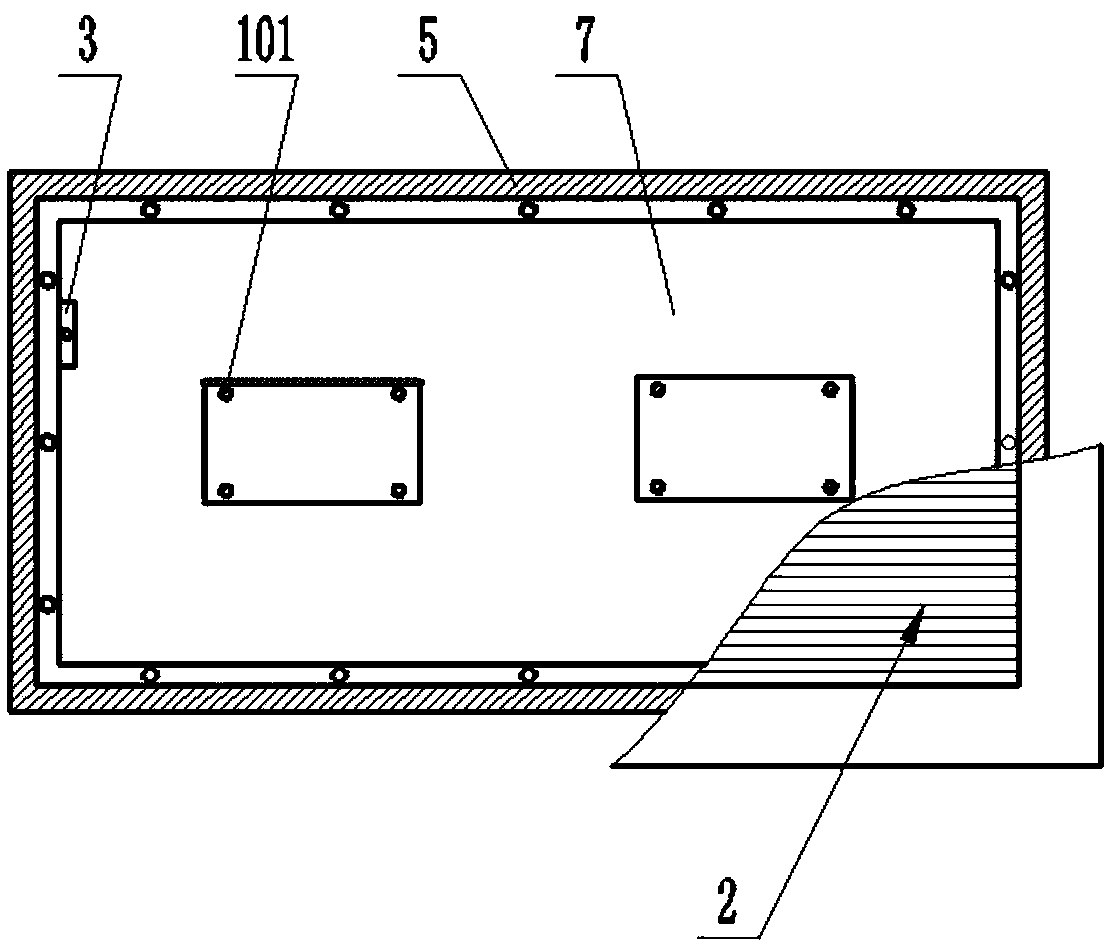

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention provides a fire oven using a mica heating plate, comprising a mica heating plate 1, a cover plate 2, a travel switch 3, a control device 4 and a box body 5 with an opening on the top surface, and a step 501 is provided on the inner wall of the box A plurality of blind holes 502 are arranged on the top surface of the step 501, and an elastic member 503 is placed in each blind hole 502, the travel switch 3 is installed on the side wall of the step 501, and the cover plate 2 is laid flat on the top surface of the step 501 And in contact with the elastic member 503, the mica heating plate 1 is installed in the box body 5 and arranged under the cover plate 2, the control device 4 is installed on the outer wall of the box body 5 and is electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com