Power cyclic test method and system for semiconductor devices

A power cycle and test method technology, applied in the direction of single semiconductor device test, semiconductor working life test, etc., can solve the problems that affect the reliability of power cycle test equipment, low measurement efficiency, and affect the reliability of DC power supply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

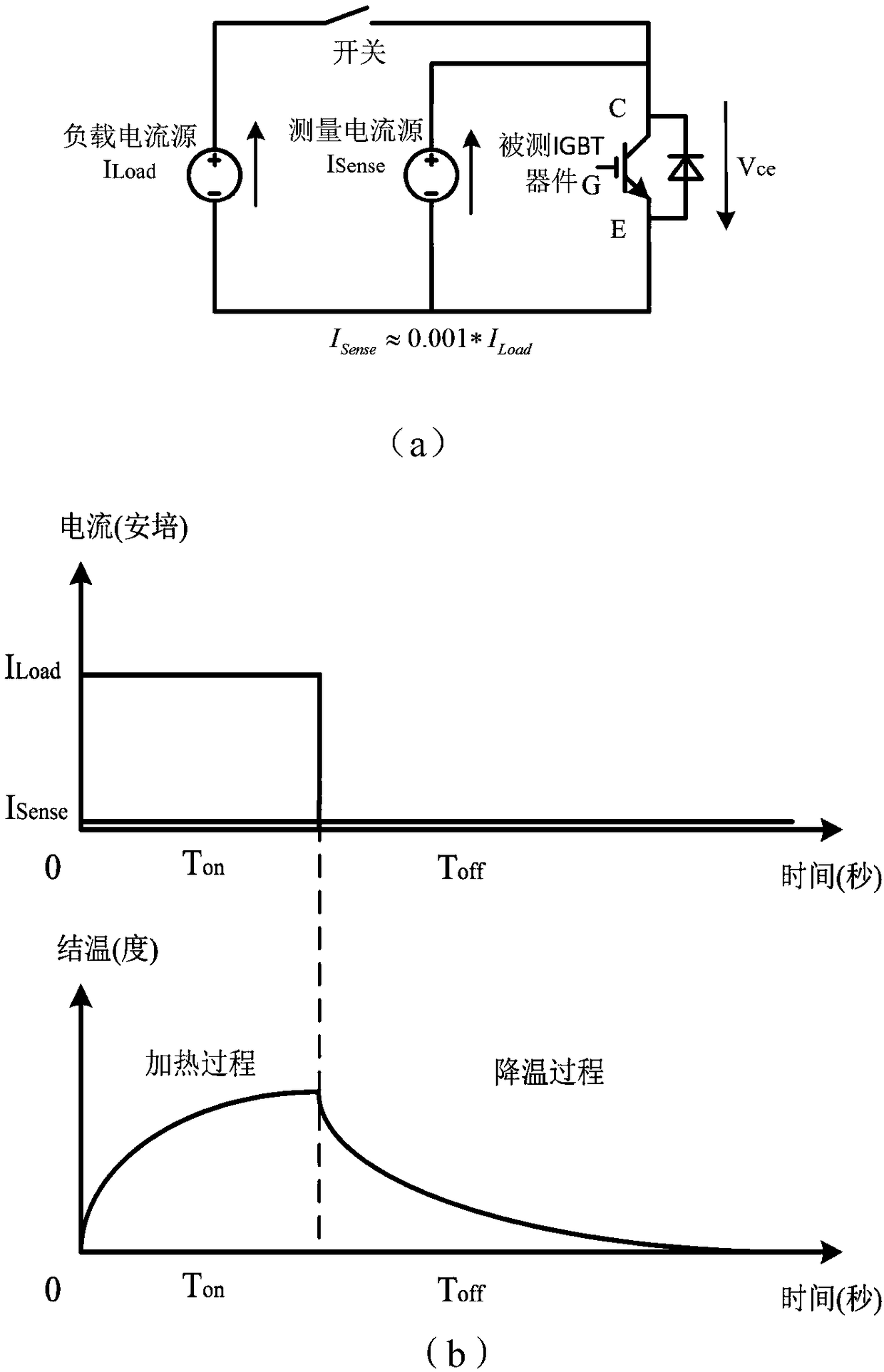

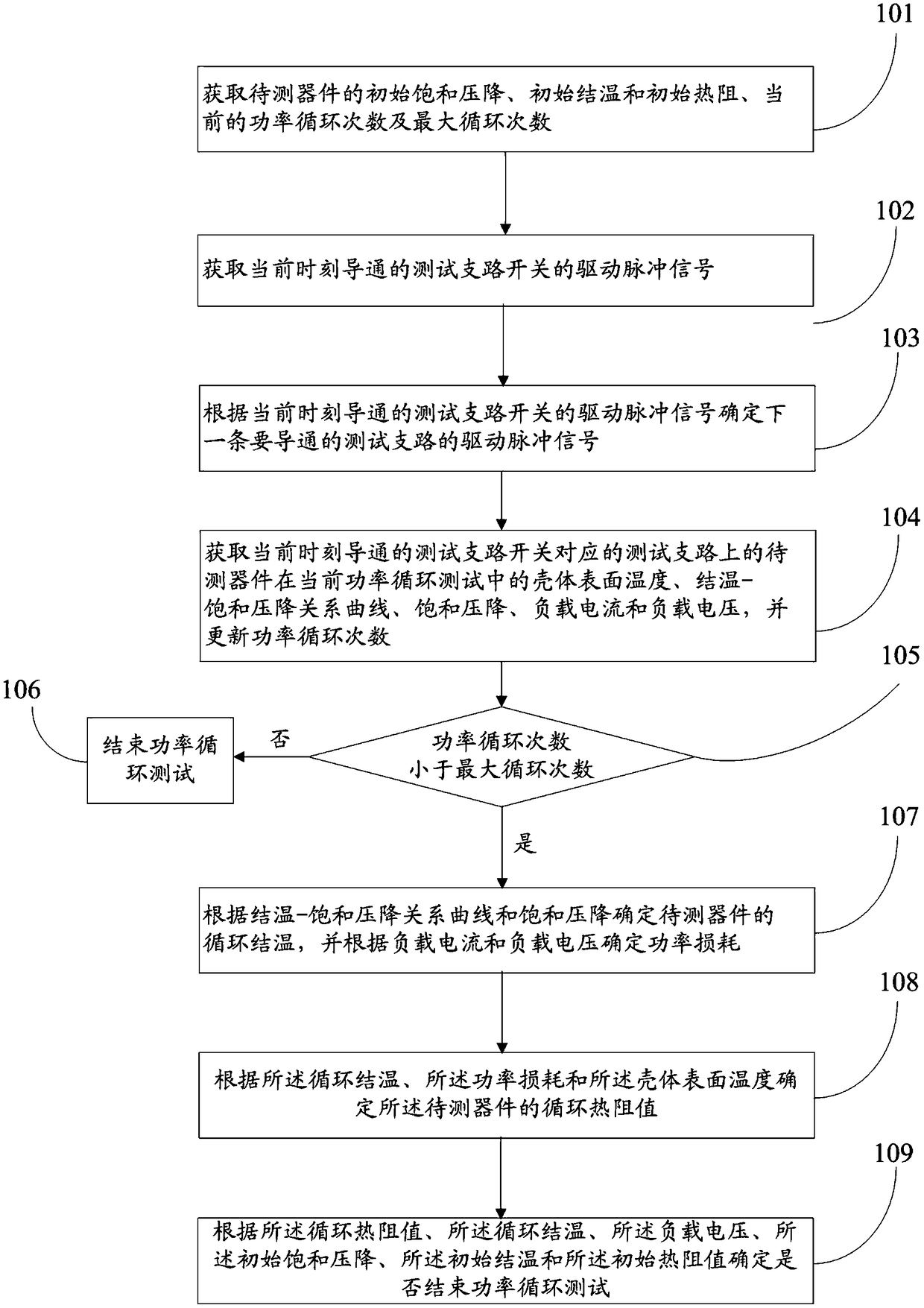

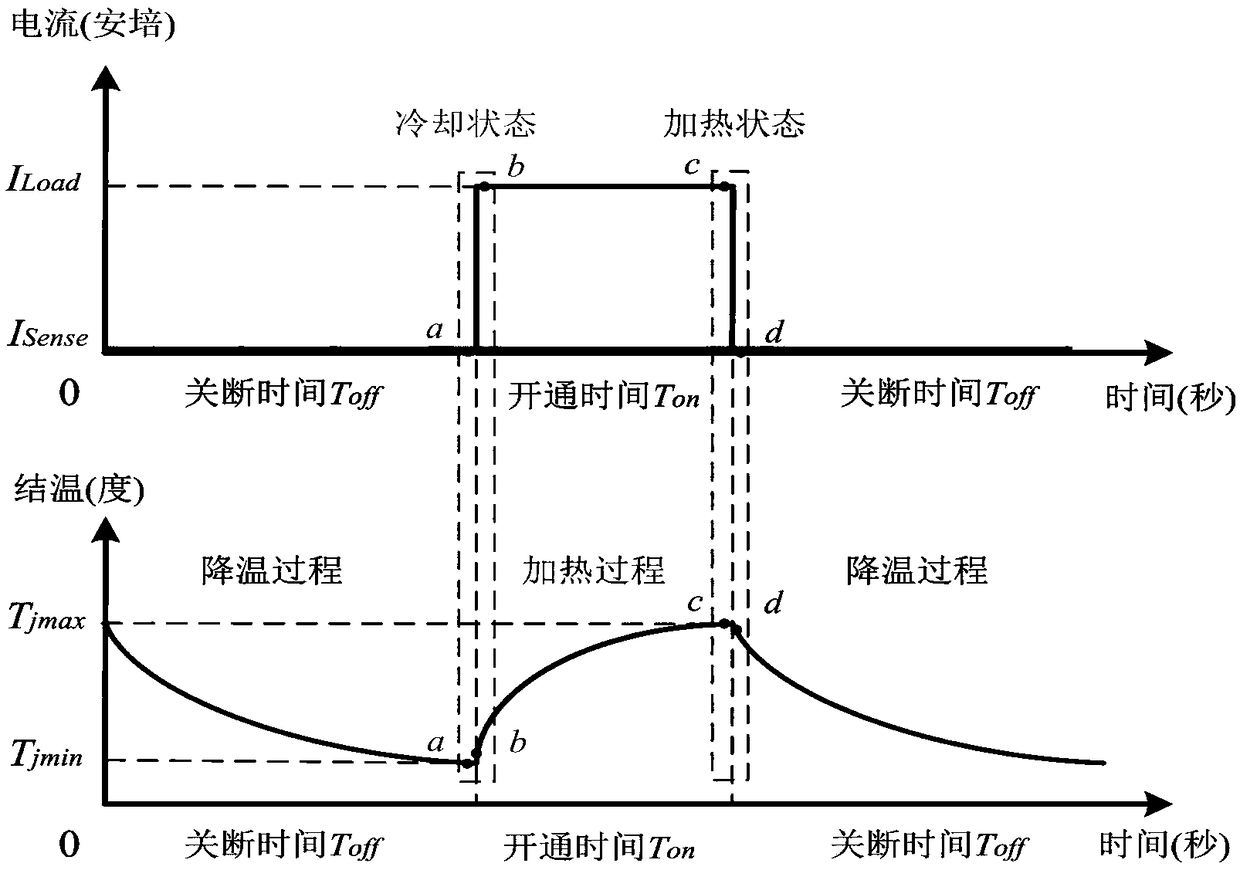

[0078] figure 2 It is a flowchart of a power cycle testing method for a semiconductor device provided in Embodiment 1 of the present invention. Such as figure 2 As shown, the power cycle test method of the semiconductor device is applied to a power cycle test device, and the power cycle test device includes a plurality of test branches connected in parallel, a DC power supply and a water cooler, and each test branch includes: A test branch switch, a number of devices under test connected in series with the test branch switch, and each of the devices under test is connected in series, each of the test branches is connected to the DC power supply to form a closed loop, and each The test branch switch is only turned on once in a power cycle test cycle, the DC power supply is used to provide a constant load current for the test branch, the water cooler is set corresponding to the test branch, and the water cooler is used To cool each of the devices under test; the power cycle ...

Embodiment 2

[0128] Figure 7 A structural block diagram of a power cycle testing system for a semiconductor device provided in Embodiment 2 of the present invention. Such as Figure 7 As shown, the power cycle test system of semiconductor devices, the power cycle test system is applied to the power cycle test device, the power cycle test device includes a plurality of test branches connected in parallel, DC power supply and water cooler, each of the The test branch includes: a test branch switch, a number of devices under test connected in series with the test branch switch, and each of the test devices is connected in series, each of the test branches is connected to the DC power supply to form a closed circuit, and each test branch switch is only turned on once in a power cycle test period, the DC power supply is used to provide a constant load current for the test branch, and the water cooler is set corresponding to the test branch , the water cooler is used to cool each of the devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com