Self-regulation temperature control heater for spacecraft

A heater and self-regulating technology, applied in auxiliary controllers with auxiliary heating devices, using electric methods for temperature control, etc., can solve the problem that the temperature stability of the controlled object is difficult to control, and the temperature stability of the controlled object is greatly affected Large, difficult to adapt to real-time changes in the external environment, etc., to achieve the effects of easier temperature stability control, lower system costs, and avoid shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

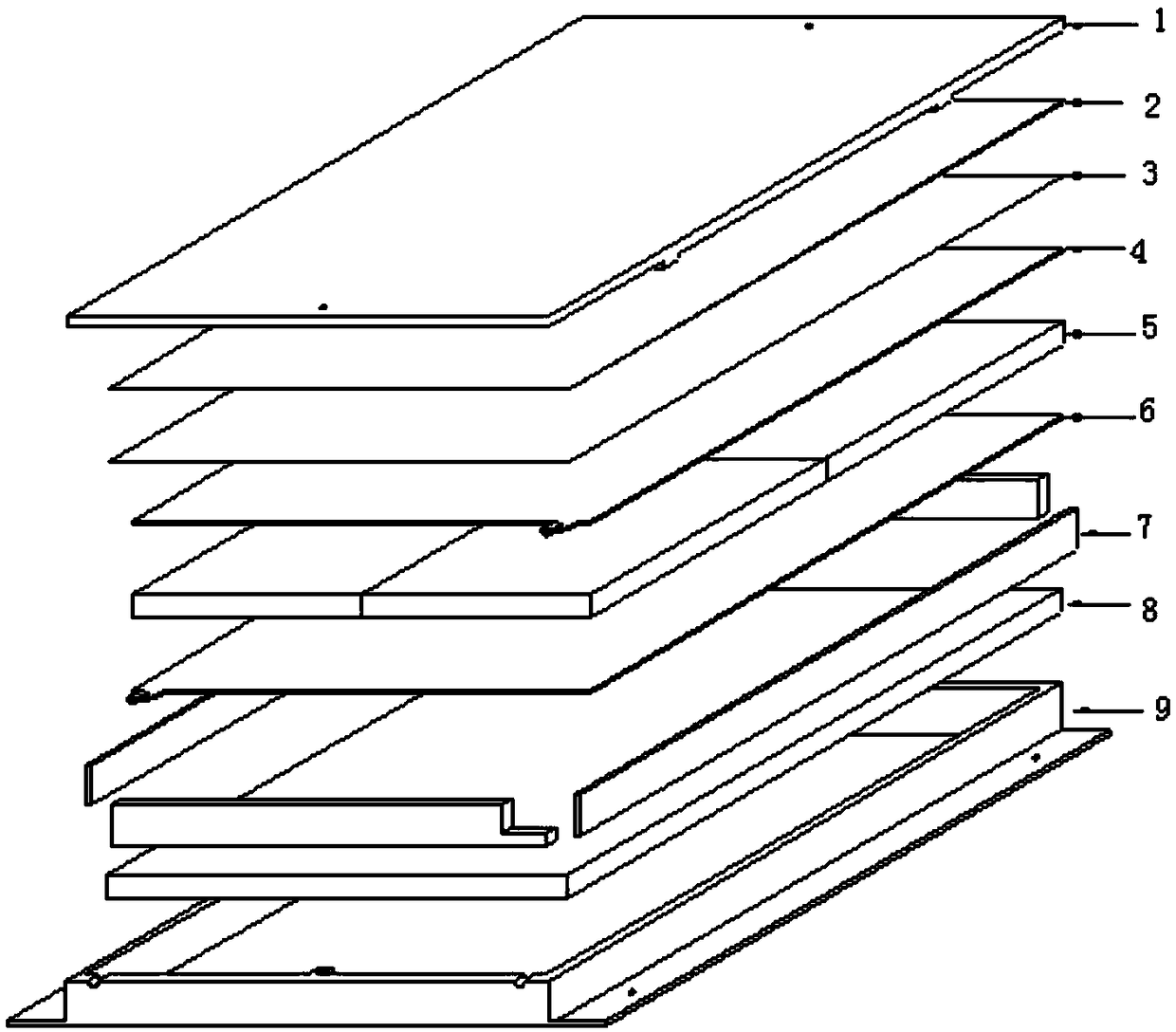

[0035] See attached figure 1 , This embodiment provides a self-regulating temperature control heater for a spacecraft, including: a cover plate 1, a heat insulating layer 2, an insulating layer 3, a positive conductive sheet 4, a PTC heating element 5, a negative conductive sheet 6, an insulating sheet 7, Heat insulating gasket 8 and base structure 9;

[0036] The PTC heating element 5 is installed in the heater shell composed of the cover plate 1 and the base structure 9; the cover plate 1 is the upper surface shell of the heater, which is used for fixing the PTC heating element 5 and the positive conductive sheet 4, the negative The installation and compression of the conductive sheet 6; the base structure 9 is used to fix the PTC heating element 5 and provide an external installation interface for the heater;

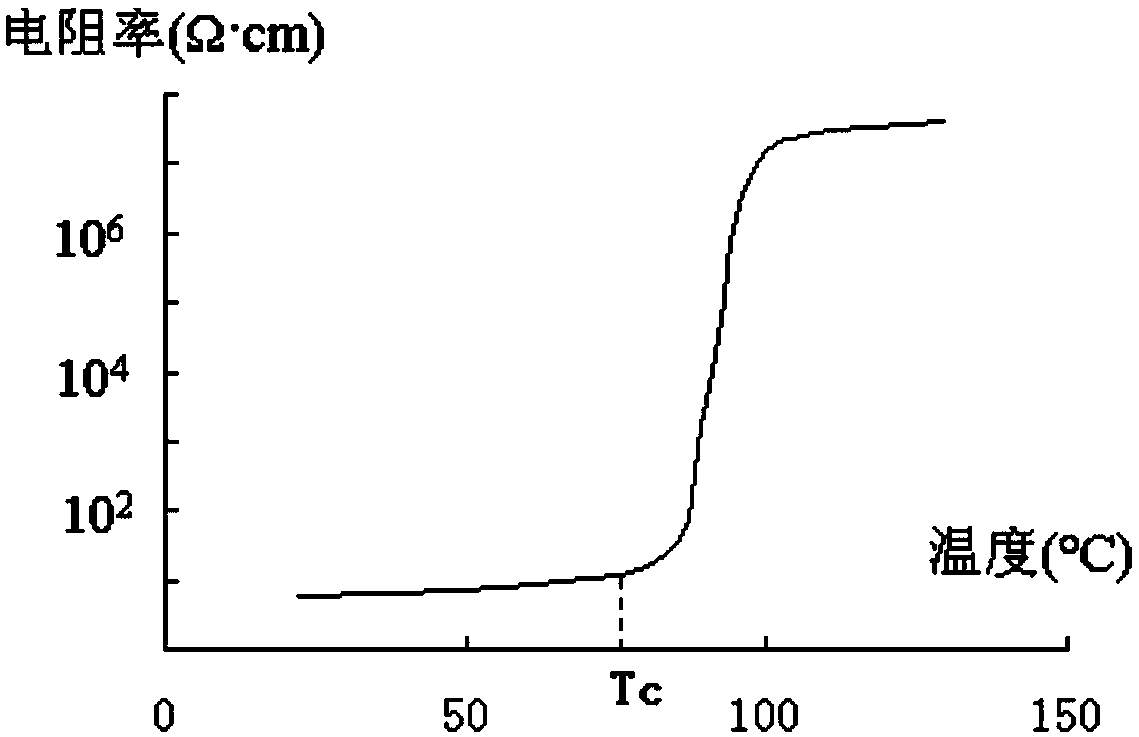

[0037] See attached figure 2 , the PTC heating element 5 is composed of a PTC material 52 with a conductive coating 51 on the upper and lower surfaces, and the PT...

Embodiment 2

[0048] On the basis of Example 1, cover plate 1, heat insulating layer 2, insulating layer 3, positive conductive sheet 4, PTC heating element 5, negative conductive sheet 6, insulating sheet 7, heat insulating gasket 8 and base structure 9 Make specific restrictions:

[0049] The PTC heating element 5 adopts a highly stable ceramic-based material. In order to ensure reliable electrical contact between the PTC material 52 and the positive conductive sheet 4 and the negative conductive sheet 6, the upper and lower surfaces of the PTC material are coated with a conductive coating 51 respectively. 51 is conductive silver paste;

[0050] The size of a single PTC heating element 5 is 40mm×20mm×2mm, and the Curie temperature point is 50°C. In this example, four PTC heating elements 5 are used for the heater, and the four heating elements are arranged in parallel.

[0051] The positive conductive sheet 4 and the negative conductive sheet 6 are made of 0.1mm thick 2A12 aluminum alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com