A process fire extinguishing method for a flammable liquid storage tank

A storage tank and liquid technology, applied in the field of process fire extinguishing of combustible liquid storage tanks, can solve problems such as shortening combustion time, easy re-ignition, loss of stored materials, etc., to reduce the possibility of explosion and fire, and shorten the time of heat radiation. , the effect of reducing the cost of acquisition and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: 100,000 cubic meters of crude oil storage tank fire extinguishing

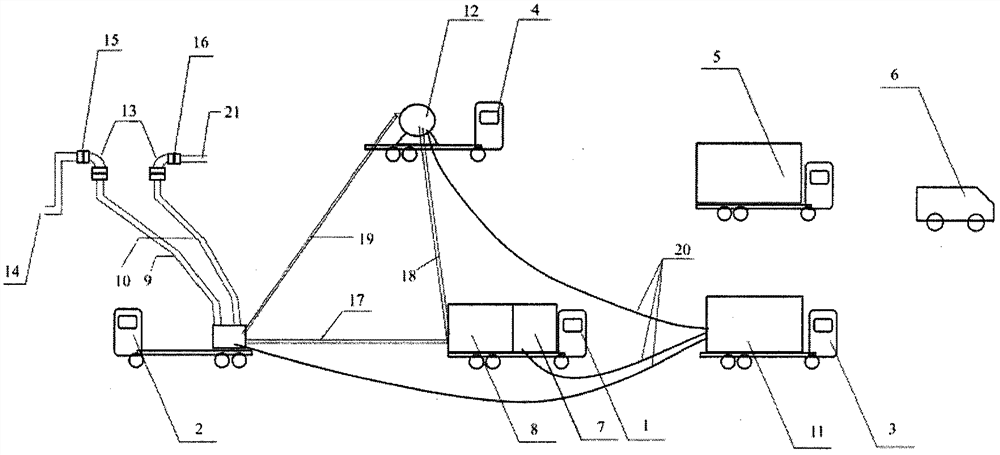

[0034] When a fire breaks out in a crude oil storage tank, in addition to organizing the existing firefighting forces for self-rescue, immediately notify the mobile cooling system to go to the fire scene. The composition of the mobile cooling system is as follows: figure 1 shown.

[0035] The mobile cooling system is composed of a refrigeration system, a heat exchange system, a pipeline system, a pipe diameter conversion system, a power system, a conveying system, an auxiliary system and a command system, wherein the refrigeration system and the heat exchange system are integrated into a heat exchange vehicle 1 , the pipeline system is integrated into pipeline vehicle 2, the power system is integrated into power vehicle 3, the delivery system is integrated into pump vehicle 4, the pipe diameter conversion system and auxiliary system are integrated into auxiliary tool vehicle 5, and the comman...

Embodiment 2

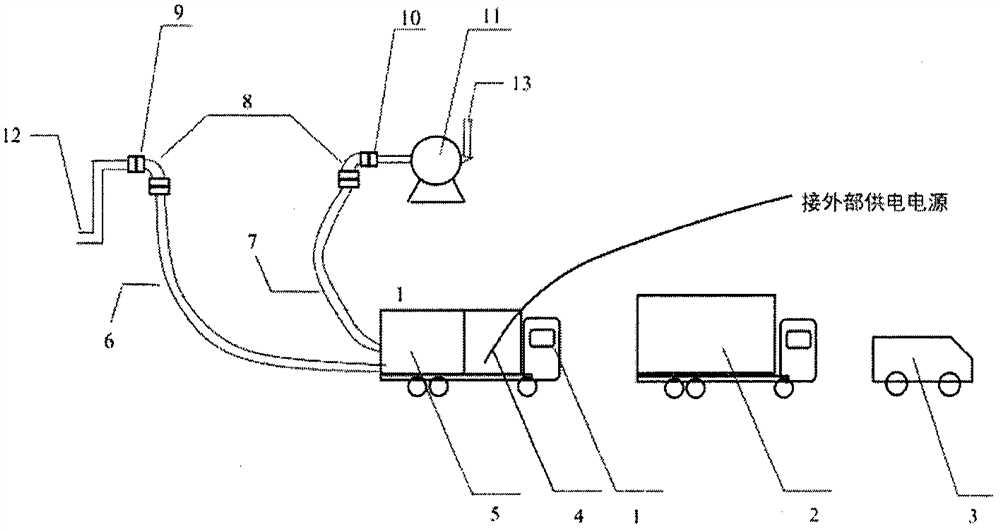

[0042] Example 2: 10,000 cubic meters of diesel storage tank fire extinguishing

[0043] When a fire breaks out in the diesel storage tank, in addition to organizing the existing firefighting forces to rescue themselves, immediately notify the mobile cooling system to go to the fire scene. The composition of the mobile cooling system is as follows: figure 2 shown.

[0044] The mobile cooling system is composed of a refrigeration system, a heat exchange system, a pipeline system, a pipe diameter conversion system, an auxiliary system and a command system, wherein the refrigeration system and the heat exchange system are integrated into a heat exchange vehicle 1, and the pipeline system, pipe The path conversion system and the auxiliary system are integrated into the auxiliary tool vehicle 2, and the command system is integrated into the command vehicle 3. The heat exchange cart 1 is equipped with an ammonia refrigerator 4 and a plate-fin heat exchanger 5, and the auxiliary to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com