A high-efficiency shearing device for plate parts

A technology of shearing device and plate parts, which is applied in the direction of shearing device, attachment device of shearing machine, shearing machine equipment, etc., can solve problems such as inapplicability, and achieve the effects of avoiding secondary cutting, high safety, and avoiding collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

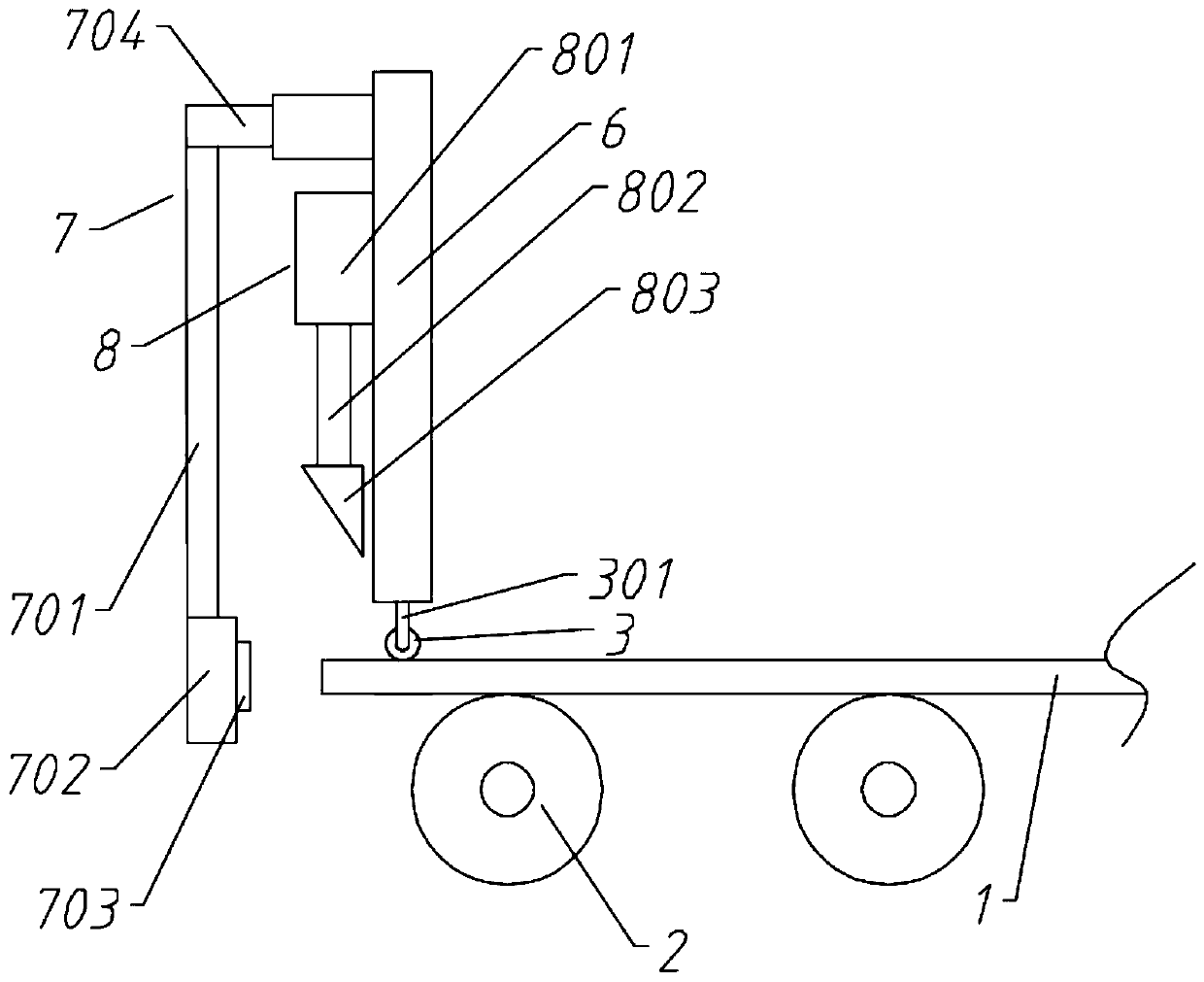

[0036] A high-efficiency shearing device for plates, including a driving roller shaft 2, a limit assembly 7 and a shear assembly 8;

[0037] The driving roller shaft 2 is evenly laid under the plate 1; the driving roller shaft 2 is externally connected with a motor, and the motor is provided with a power supply;

[0038] A support plate 6 is provided above the forward end of the plate 1, and a limit assembly 7 and a shear assembly 8 are provided on the front side of the support plate 6;

[0039] The limit assembly 7 includes an adjustment cylinder 704, a connecting rod 701 and a limit block 702. The adjustment cylinder is installed horizontally on the support plate 6. One end of the connection rod 701 is connected to the telescopic end of the adjustment cylinder 704, and the other end extends vertically downward and connects to the limit block. Block 702; the limit block 702 is provided with a contact switch corresponding to the plate 1;

[0040] The cutting assembly 8 includ...

Embodiment 2

[0042] A high-efficiency shearing device for plates, including a driving roller shaft 2, a limit assembly 7 and a shear assembly 8;

[0043] The driving roller shaft 2 is evenly laid under the plate; the driving roller shaft 2 is connected with a motor, and the motor is provided with a power supply;

[0044] A support plate 6 is provided above the forward end of the plate 1, and a limit assembly 7 and a shear assembly 8 are provided on the front side of the support plate 6;

[0045] The limiting assembly 7 includes an adjusting cylinder 704, a connecting rod 701 and a limiting block 702. The adjusting cylinder 704 is horizontally installed on the support plate 6. One end of the connecting rod 701 is connected to the end plate, and the other end extends vertically downward and connects to the limiting block 702. ; The limit block 702 is provided with a contact switch corresponding to the plate 1;

[0046] The shearing assembly 8 includes a hydraulic cylinder 801 and a cutter 8...

Embodiment 3

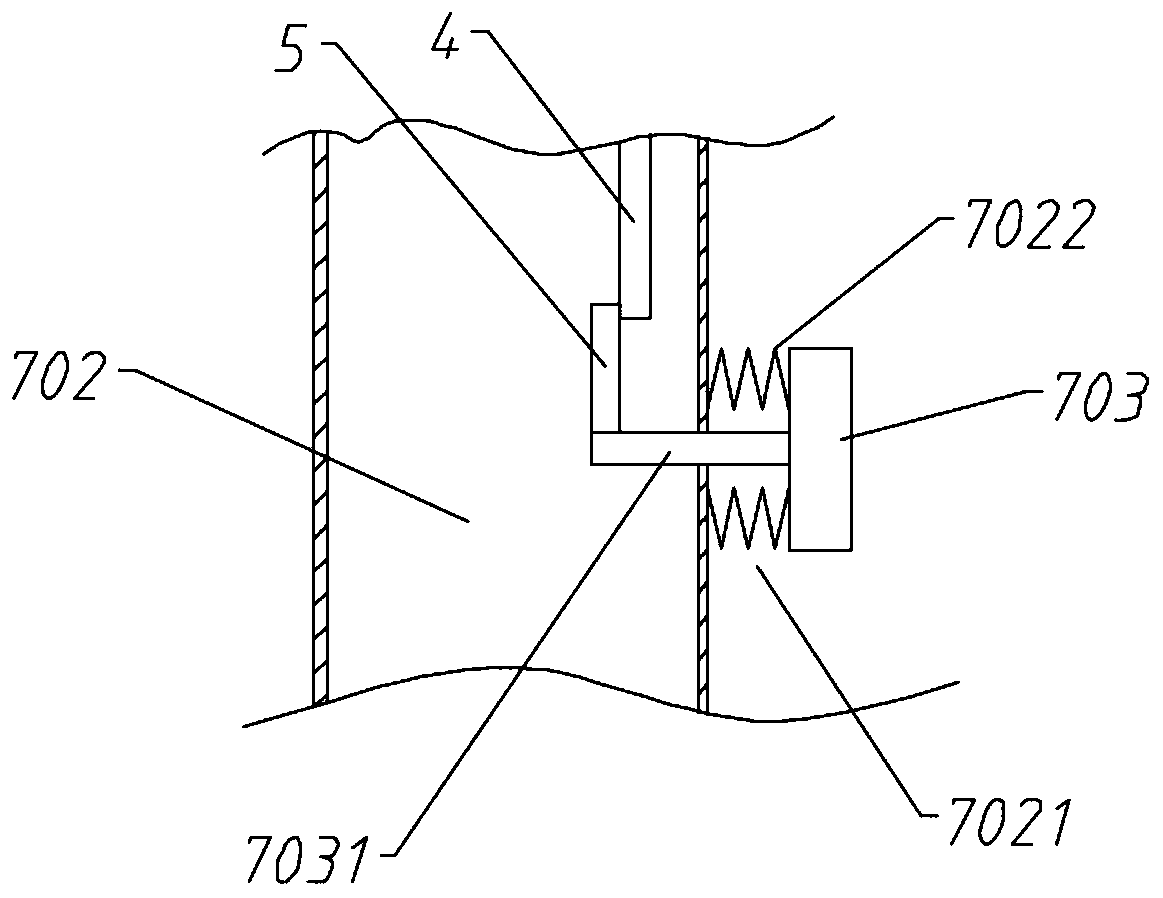

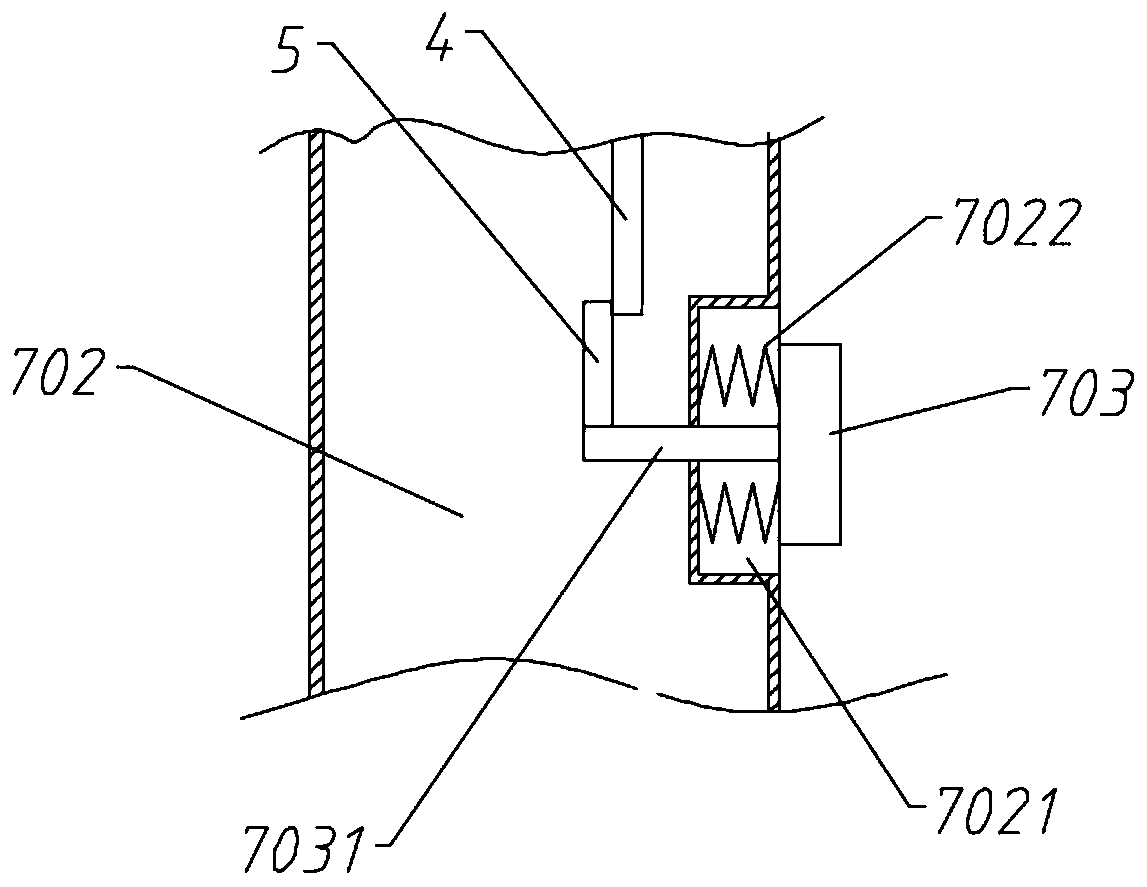

[0052] The limit block 702 is provided with a groove 7021 corresponding to the pressure block, and the spring 7022 is arranged between the groove 7021 and the pressure block to prevent overpressure. The limit block 702 plays a blocking role after the pressure block 703 enters the groove 7021 completely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com