Multi-cylinder synchronous lifting mechanism

A technology of left cylinder and throttle valve, applied in the direction of lifting device, etc., can solve the problems of rollover of heavy objects, inability to achieve synchronization of lifting speed and position, deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

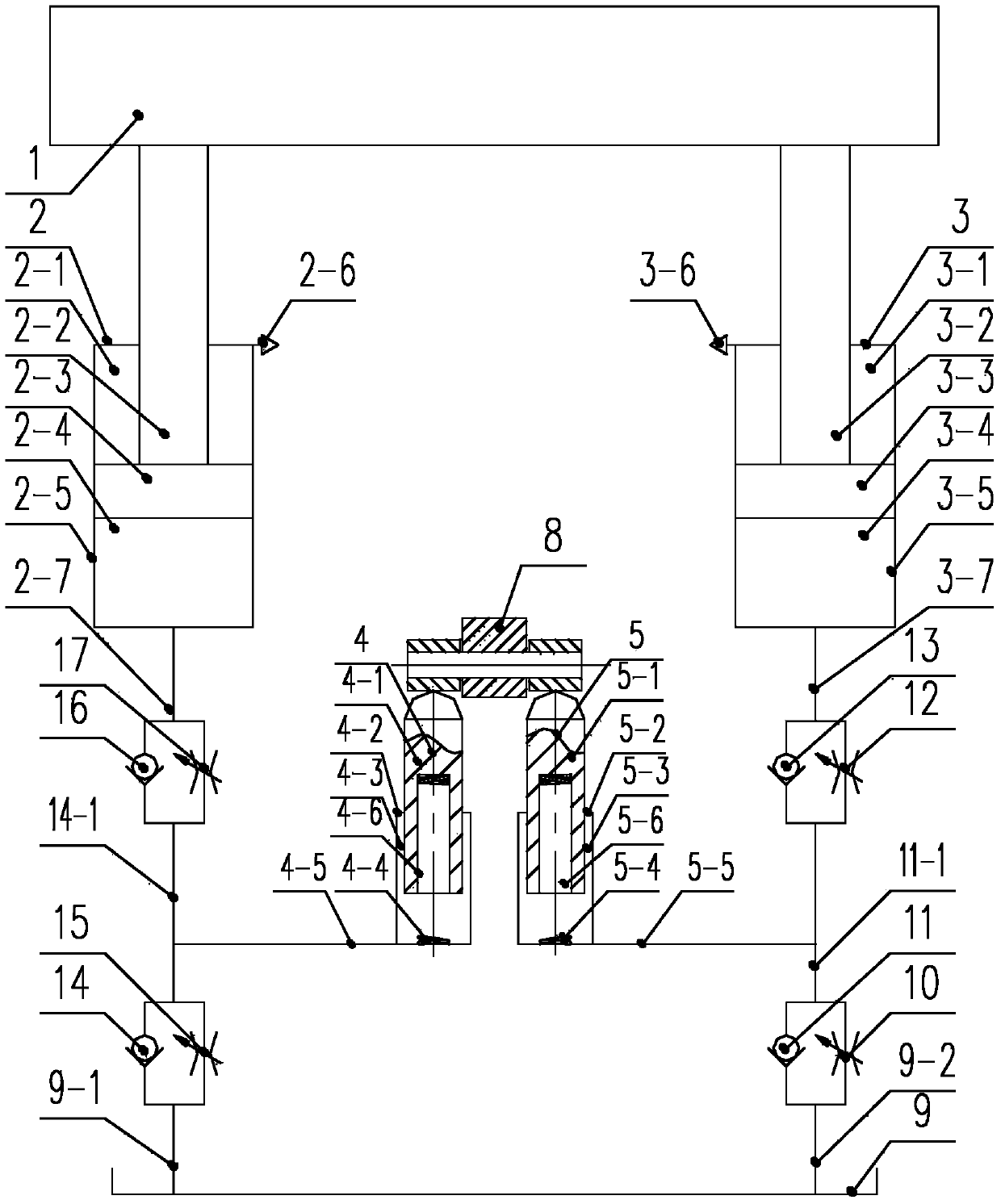

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

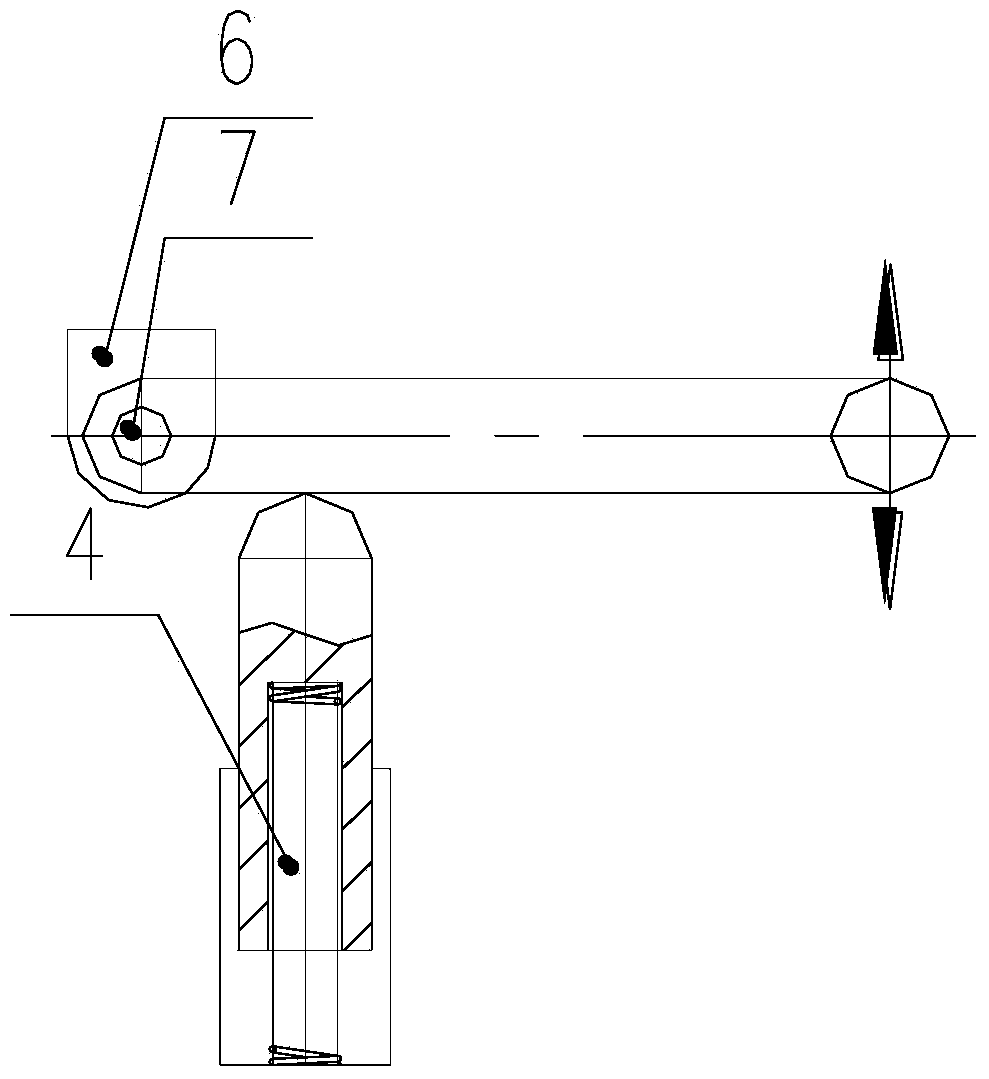

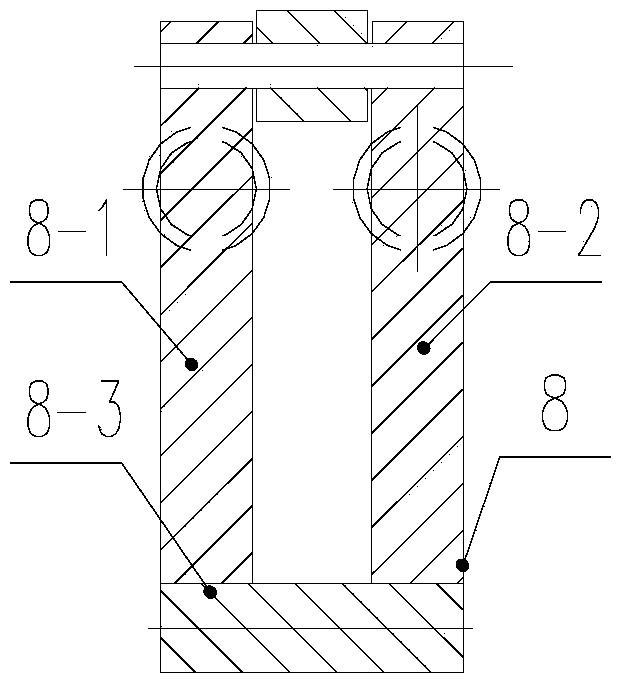

[0024] Such as figure 1As shown, a multi-cylinder synchronous lifting mechanism includes: left lifting cylinder 2, right lifting cylinder 3, left loader 4, right loader 5, pin seat 6, pin shaft 7, pressure rod assembly 8, fuel tank 9, the first A throttle valve 10, a second throttle valve 12, a third throttle valve 15, a fourth throttle valve 17, a first check valve 11, a second check valve 13, a third check valve 14, a fourth check valve One-way valve 16 and several pipelines, pipelines include pipeline one 2-7, pipeline two 3-7, pipeline three 14-1, pipeline four 11-1, pipeline five 4-5, pipeline six 5-5, pipeline seven 9-1, pipeline eight 9-2.

[0025] The left lifting cylinder 2 and the right lifting cylinder 3 are respectively arranged on the left and right sides below the weight 1 lifted by the mechanism. Left lifting cylinder 2 includes left cylinder upper ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com