A kind of anti-dust equipment for construction site

A construction site, anti-dust technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as the inability to actively reduce air dust content, achieve good dust removal effect and reduce power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

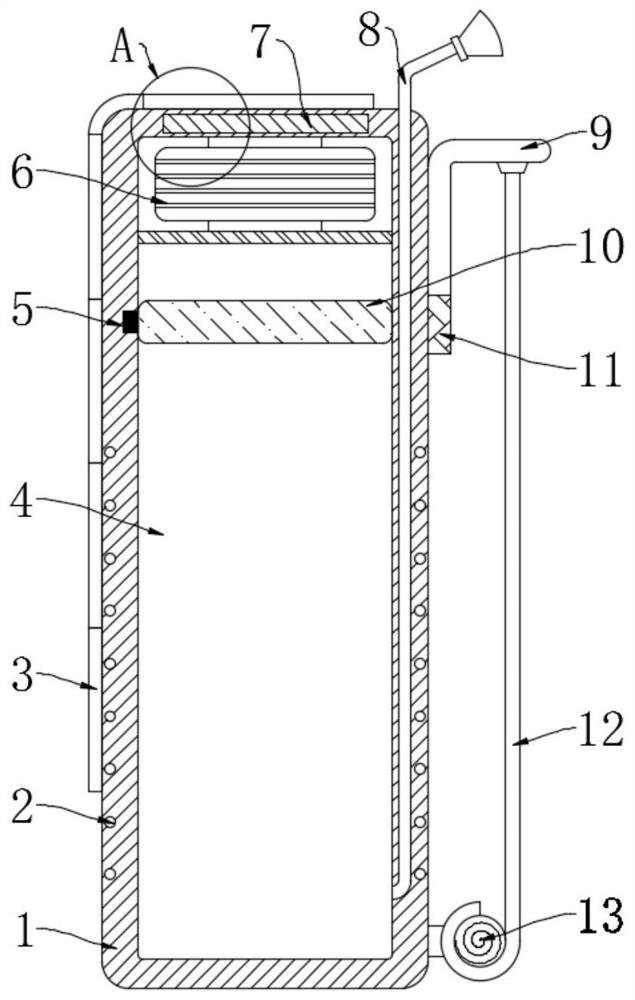

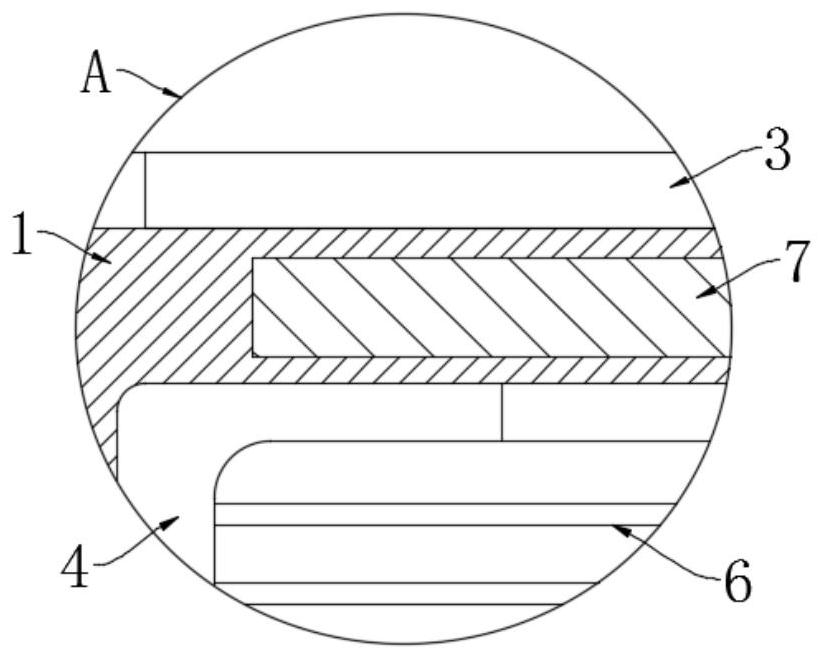

[0024] refer to Figure 1-2 , a kind of anti-dust equipment for a construction site, comprising a fixed plate 1, a hollow groove 4 is opened in the fixed plate 1, an electromagnetic coil 6 is fixedly installed on the inner top wall of the hollow groove 4, and a permanent magnet is arranged for sealing and sliding in the hollow groove 4 10. A plurality of photovoltaic panels 3 are arranged in an array on the outer wall of the fixed plate 1. The wire group 2, the touch panel 5 and the circuit board 7 are fixed inside the side wall of the fixed plate 1, and the circuit board 7 is connected with the wires. The group 2 is respectively located above and below the electromagnetic coil 6, and the touch panel 5 is located between the wire group 2 and the electromagnetic coil 6;

[0025] A storage battery (not shown) electrically connected to the photovoltaic panel 3, the touch panel 5, the electromagnetic coil 6, and the circuit board 7 is also arranged in the fixed plate 1, and the wi...

Embodiment 2

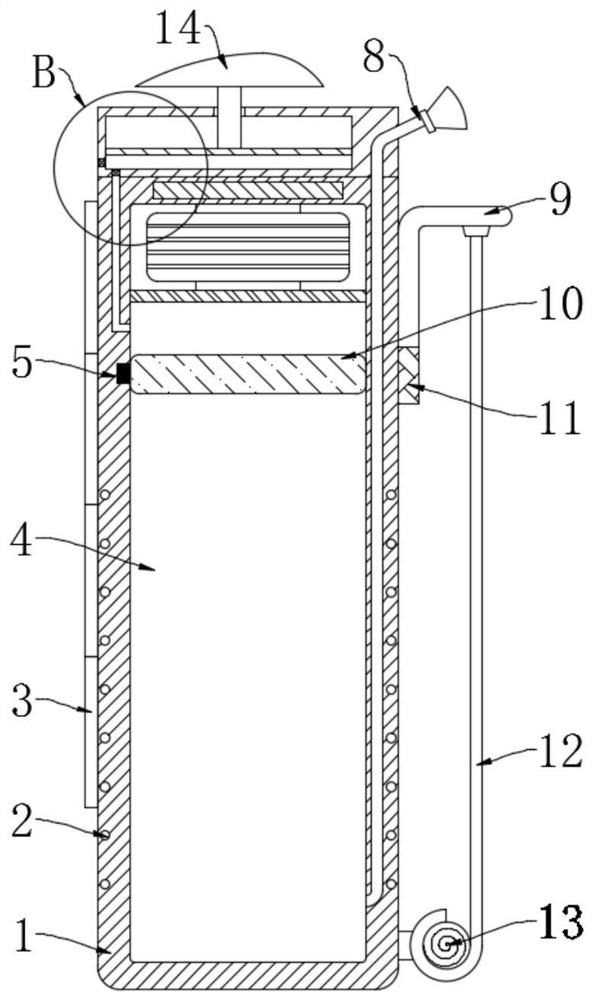

[0038] refer to Figure 2-4 , the present embodiment differs from Embodiment 1 in that: the upper end of the fixed plate 1 is fixedly provided with a sealing box 15, and a sliding plate 16 is arranged for sealing and sliding in the sealing box 15, and a straight rod is welded on the sliding plate 16, and the upper end of the straight rod Through the top of the sealing box 15 and connected with the wing plate 14, the side wall of the sealing box 15 is provided with an air inlet 17 and an exhaust port 19, and the air inlet 17 is connected with the hollow groove 4 through an elbow 18, and the elbow The junction of the tube 18 and the hollow slot 4 is located above the permanent magnet 10 .

[0039] In this embodiment, a one-way valve is installed in the air inlet 17 and the exhaust port 19. Under the action of the one-way valve, the air can only flow along the hollow groove 4-intake port 17-sealed box 15-exhaust port 19 direction of movement.

[0040] When the equipment is in u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com