Translational shoe-hub type brake

A technology of hub brakes and brakes, which is applied in the direction of drum brakes, brake types, brake parts, etc., can solve the problems of unequal positive pressure and friction, unequal displacement of brake shoes, and decreased bearing capacity, etc., to achieve positive The same pressure and friction force, higher load capacity and lower manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

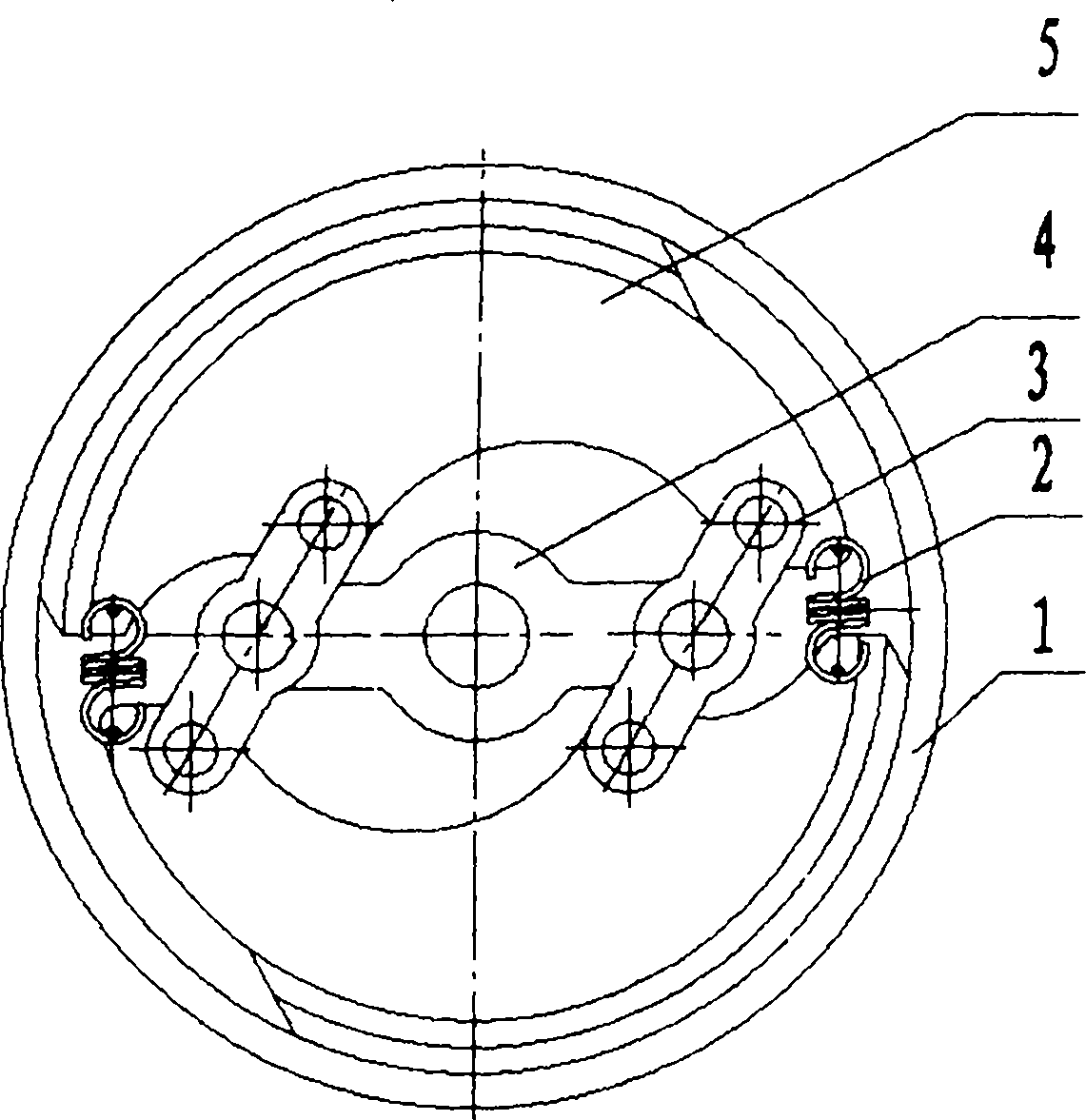

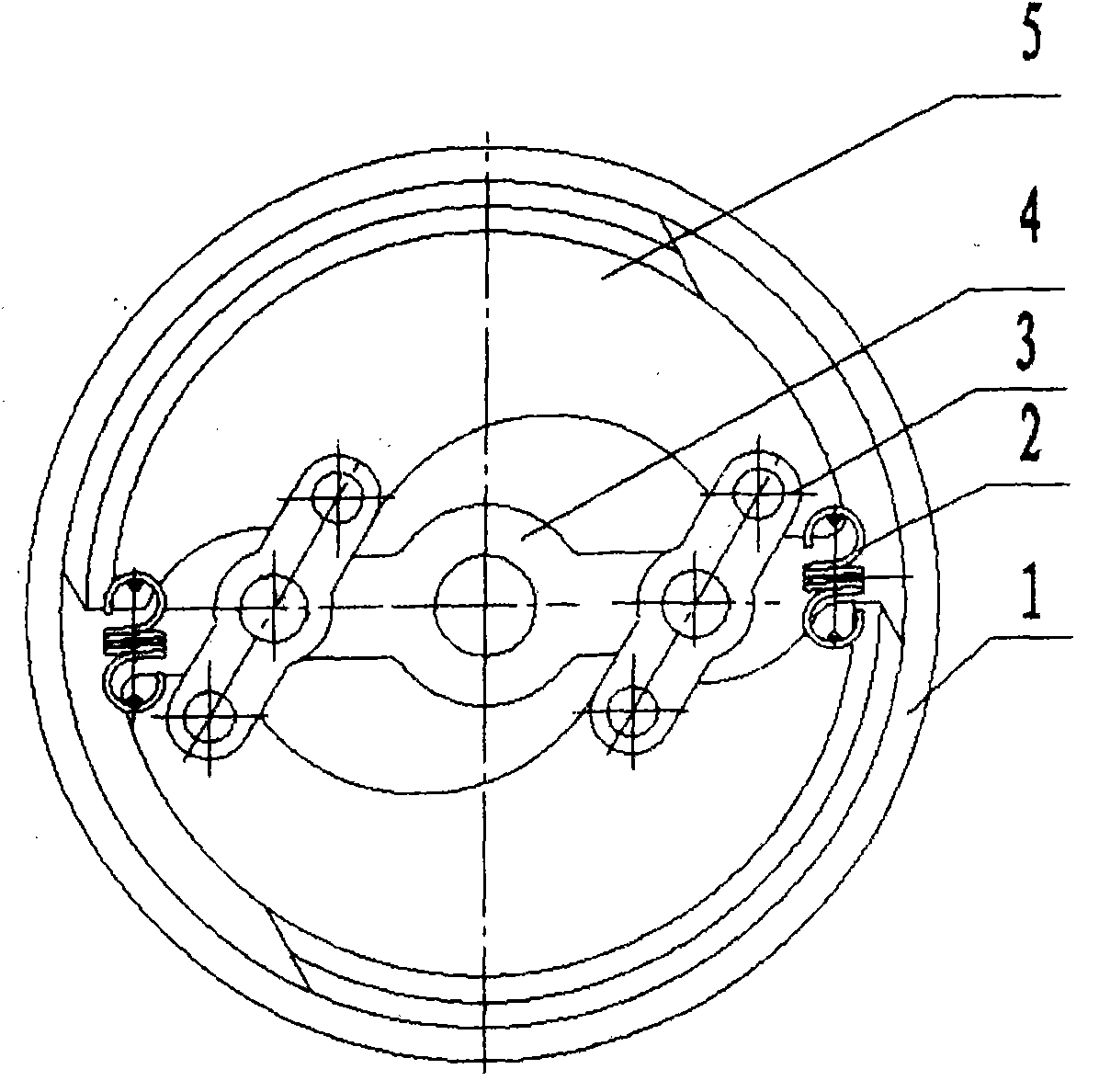

[0012] figure 1 The structure of the translational shoe-hub brake shown is: it is composed of a brake back plate 4, a wheel hub 1, a brake shoe 5, a crank 3, and a return spring 2, and the two ends of the brake back plate 4 pass through cylindrical pins and two The cranks 3 are hinged, and the two ends of the two cranks 3 are respectively connected with the two ends of the two brake shoes 5 through cylindrical pins, forming a double parallelogram mechanism. After the crank 3 and the brake cylinder of the vehicle or the piston rod (not shown) of the oil cylinder are hinged, under the action of the brake cylinder or the oil cylinder, the two equal-length cranks 3 rotate to drive the two brake shoes 5 (equivalent to the connecting rod ) translationally moving outward to extrude the hub 1 to generate positive pressure and frictional force to achieve the purpose of braking.

[0013] In order to reduce the friction force of each hinge point, each hinge point is equipped with a corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com