Portable welding device used for processing LED lamps

A technology of LED lamps and welding devices, applied in auxiliary devices, welding equipment, metal processing equipment, etc., can solve the problems of inconvenient portability, high cost, and complicated operation, and achieve the effects of easy portability, messy changes, and reduced harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

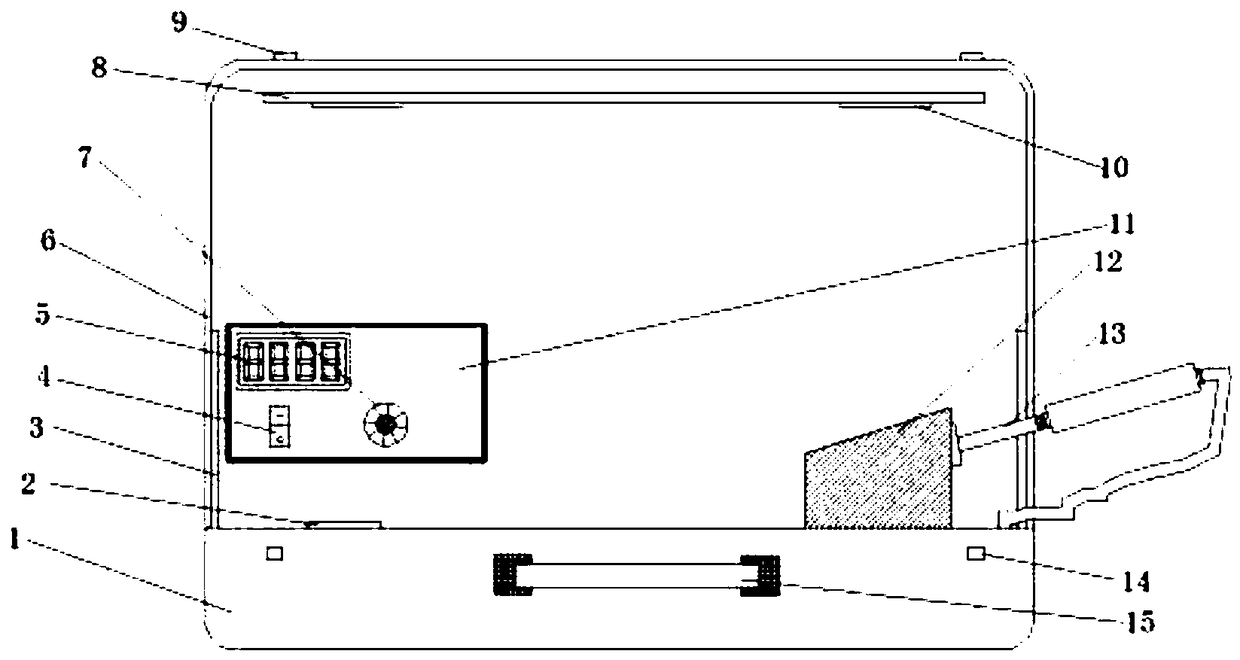

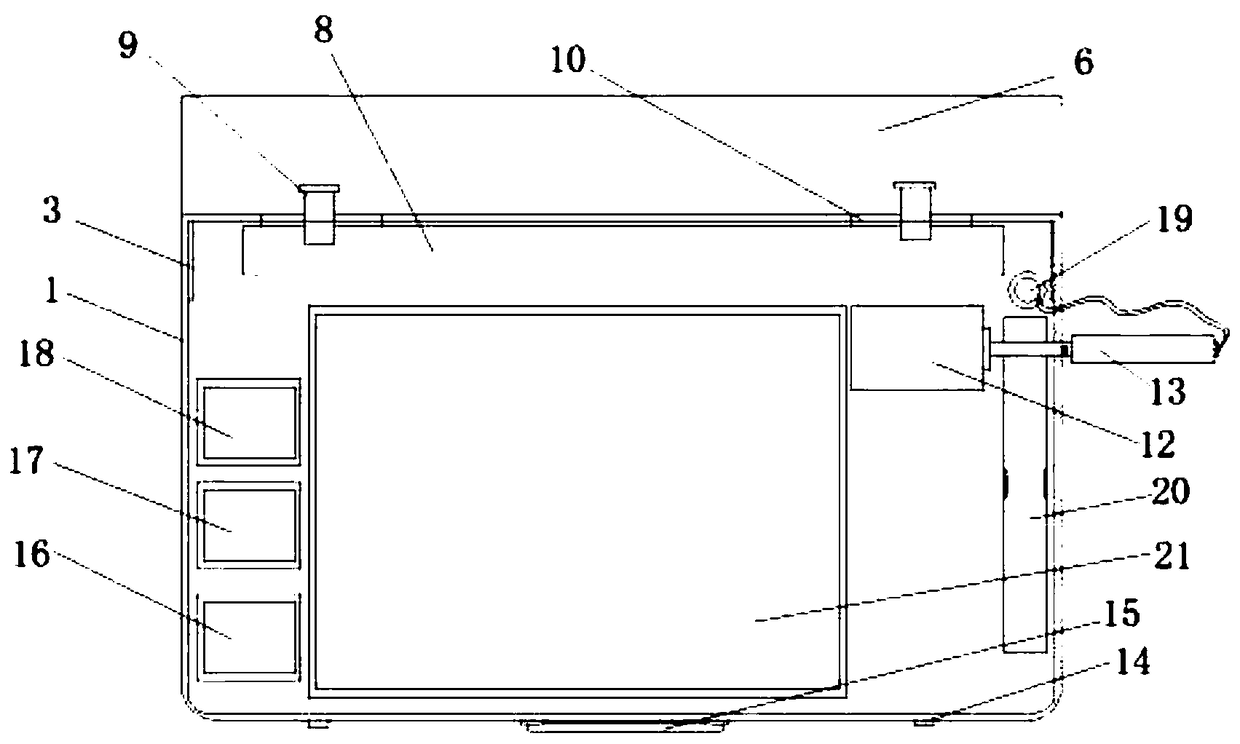

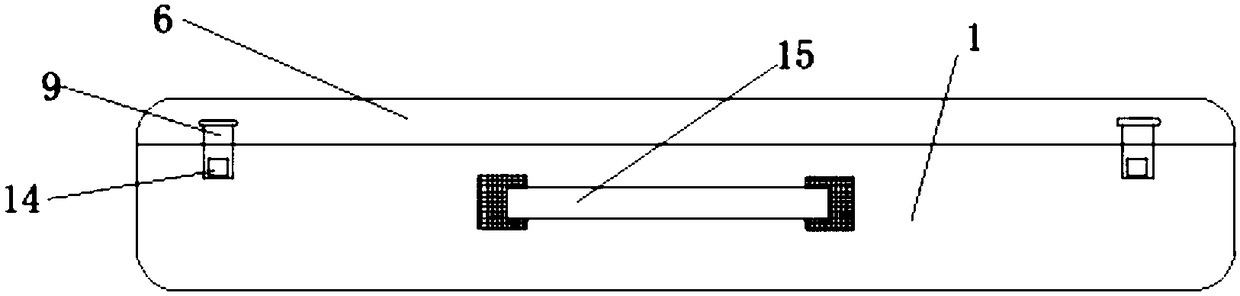

[0021] refer to Figure 1-3 , a portable welding device for LED lamp processing, comprising a box bottom 1, a box handle 15 is connected to the middle of one side of the box bottom 1 by bolts, both ends of one side of the box bottom 1 are connected to fastening bolts 14 by bolts, and the top of the box bottom 1 The center is connected with an operating platform 21 by bolts, and two hinges 2 are connected by bolts on the top side of the box bottom 1. The side of the two hinges 2 away from the box bottom 1 is connected by bolts to the box cover 6, and the top of the box cover 6 is connected by bolts. Two box buckles 9, the bottom of one side of the box cover 6 is conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap